Hydrophobic phosphogypsum, and preparation method and application thereof

A phosphogypsum, hydrophobic technology, applied in the field of phosphogypsum, can solve the problems of occupying land, polluting the environment, complex modification process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

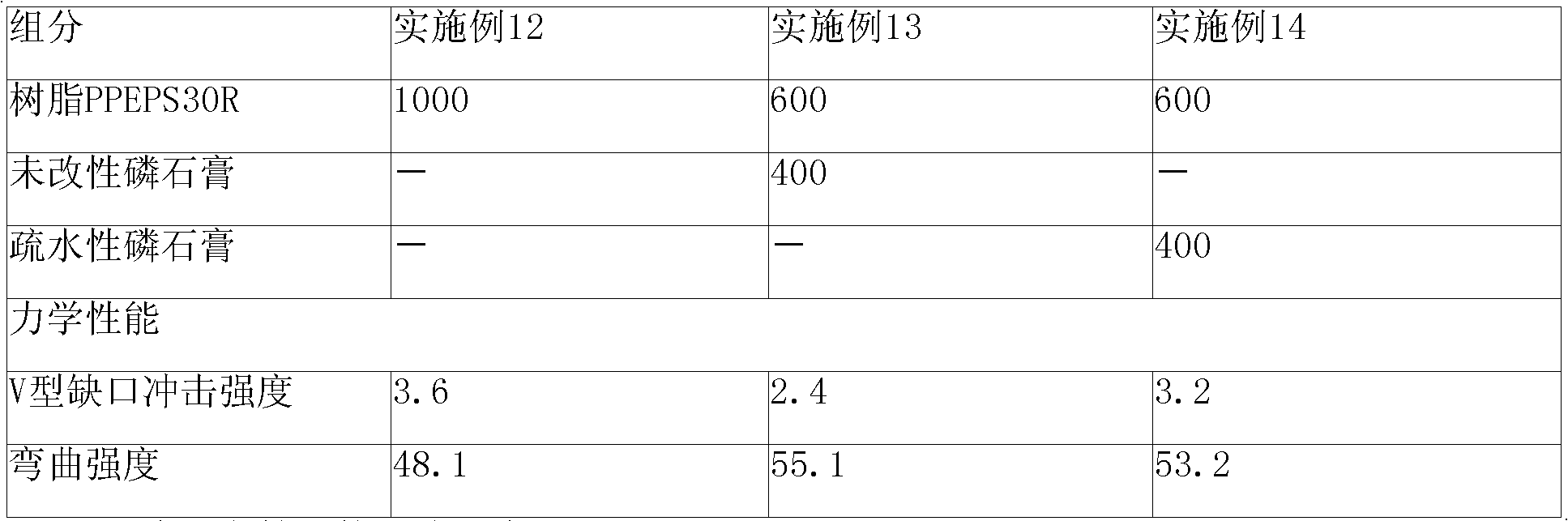

Examples

Embodiment 1

[0044] Example 1: Grind 10 g of solid waste-phosphogypsum to 100 μm, add it into deionized water, stir evenly, adjust the pH value to 7.5 with sodium hydroxide solution, heat to 80 ° C, react for 10 min, and suction filter while it is hot. After drying at 60°C, the activation index is 5%. It can be seen that the hydrophobic performance of phosphogypsum without hydrophobic modifier is very low.

Embodiment 2

[0045] Example 2: Take 10g of phosphogypsum and grind it to 500 μm for later use; another 0.05g of stearic acid solid is dissolved in deionized water to make a hydrophobic modifier solution with a mass percentage of 0.5%, and the pH value is adjusted with potassium hydroxide solution If it is 7, add phosphogypsum powder, heat to 80°C, react for 10 minutes, suction filter while hot, and dry the filter residue at 60°C to obtain hydrophobic phosphogypsum. The activation index is 40%.

Embodiment 3

[0046] Example 3: Take 10g of phosphogypsum and pulverize it to 0.1 μm for later use; another 0.05g of stearic acid solid is dissolved in deionized water to make a hydrophobic modifier solution with a mass percentage of 0.1%, and the pH is adjusted with potassium hydroxide solution When the value is 7.5, add phosphogypsum powder, heat to 80°C, react for 10 minutes, suction filter while hot, and dry the filter residue at 60°C to obtain hydrophobic phosphogypsum. The activation index is 45%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com