Coal gangue-based composite geopolymer grouting filling material and preparation method thereof

A filling material and geopolymer technology, which is applied in the field of coal gangue-based composite geopolymer grouting filling material and its preparation, can solve the problems of high stone body strength, ineffective reinforcement of roadbed, and accelerated reaction rate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

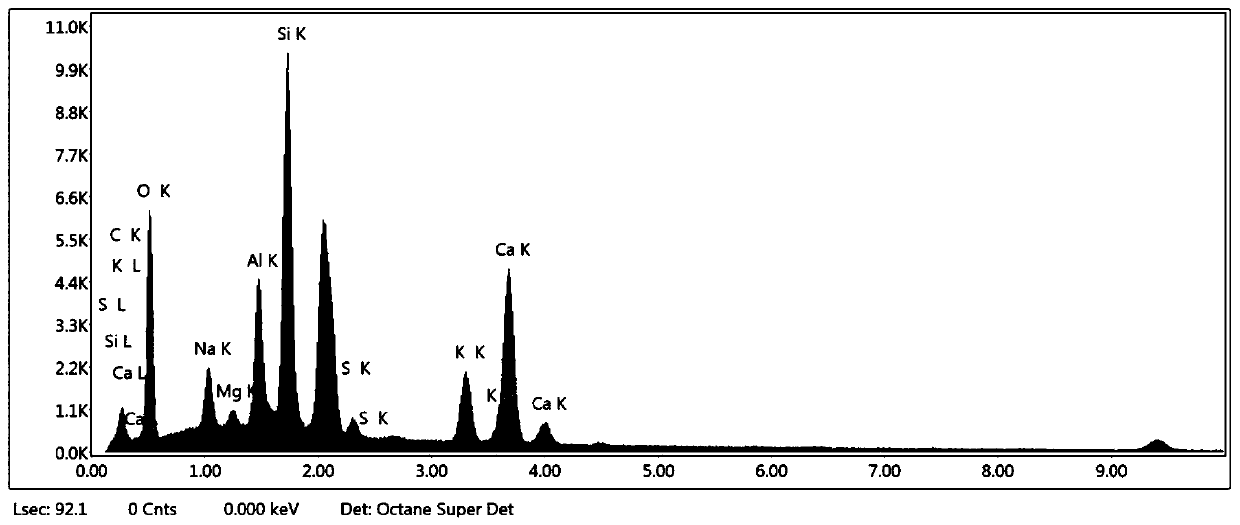

Image

Examples

preparation example Construction

[0035] A preparation method of coal gangue-based composite geopolymer grouting filling material, comprising the following steps:

[0036] Step 1), take the following raw materials in parts by mass: 100-140 parts of slag powder, 60-100 parts of coal gangue powder, 60-100 parts of water, 30-48 parts of water glass solution, 4-10 parts of KOH solid, 1 -2 parts of water reducer, 2-5 parts of toughening agent, 1-2 parts of retarder and 1 part of expansion agent;

[0037] Step 2), mix the KOH solid and the water glass solution until the KOH solid is completely dissolved to obtain the B solution. Since the KOH solid dissolves in the water glass solution and dissolves quickly and emits a large amount of heat, if a large amount is prepared, it needs to be added in batches and stirred slowly;

[0038] Step 3), dry slag powder and coal gangue powder in a blender and mix evenly, then put retarder, water reducing agent, water and toughening agent in turn and mix uniformly to obtain A mixtu...

Embodiment 1

[0042] Step 1), get the following raw materials by mass parts:

[0043] 120 parts of slag powder above grade S95, 80 parts of 325 mesh gangue powder, 80 parts of water, 40 parts of water glass solution, 5 parts of KOH solid, 1 part of water reducer, 3 parts of toughening agent, 1 part of retarder, expansion 1 dose.

[0044] Step 2), pour the weighed KOH solid into the water glass solution and stir until the KOH is completely dissolved to obtain the B solution;

[0045] Step 3), the weighed slag powder and coal gangue powder were dry-stirred and mixed evenly in a mixer, then put in water reducing agent and water in sequence, and stirred at 100r / min for 5min to obtain the A mixture;

[0046] Step 4), mix the B solution and the A mixture, and stir at 300r / min for 2min to obtain a composite geopolymer grouting material;

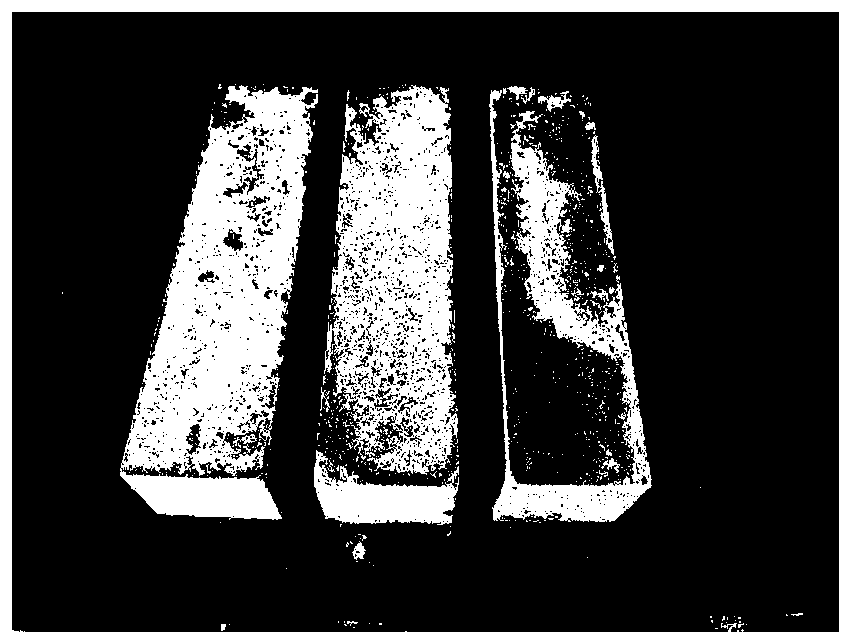

[0047] Step 5), testing the fluidity and water separation rate of the prepared grouting material, pouring the prepared grouting material into the mold, putting i...

Embodiment 2

[0050] Step 1), get the following raw materials by mass parts:

[0051] 100 parts of S95 and above blast furnace slag powder, 100 parts of coal gangue powder, 60 parts of water, 48 parts of water glass solution, 8 parts of KOH solid, 2 parts of water reducer, 4 parts of toughening agent, 2 parts of retarder, expansion agent 1 copy;

[0052] Step 2), pour the weighed KOH solid into the water glass solution and stir until the KOH is completely dissolved to obtain the B solution;

[0053] Step 3), dry-mix the weighed slag powder and coal gangue powder in a mixer, then add water reducer and water in turn, and stir at 110r / min for 5min to obtain A mixture;

[0054] Step 4), mix solution B and mixture A, and stir at 200 r / min for 3 minutes to obtain a composite geopolymer grouting material.

[0055] Step 5), testing the fluidity and water separation rate of the prepared grouting material, pouring the prepared grouting material into the mold, putting it into the curing box for 7 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com