Device and method for producing type II anhydrous gypsum from phosphogypsum

Anhydrous gypsum, phosphogypsum technology, applied in chemical instruments and methods, inorganic chemistry, calcium/strontium/barium sulfate, etc., can solve the problems of high raw material cost, impact on performance, large product fluctuation, etc. The effect of resource utilization, stable performance and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

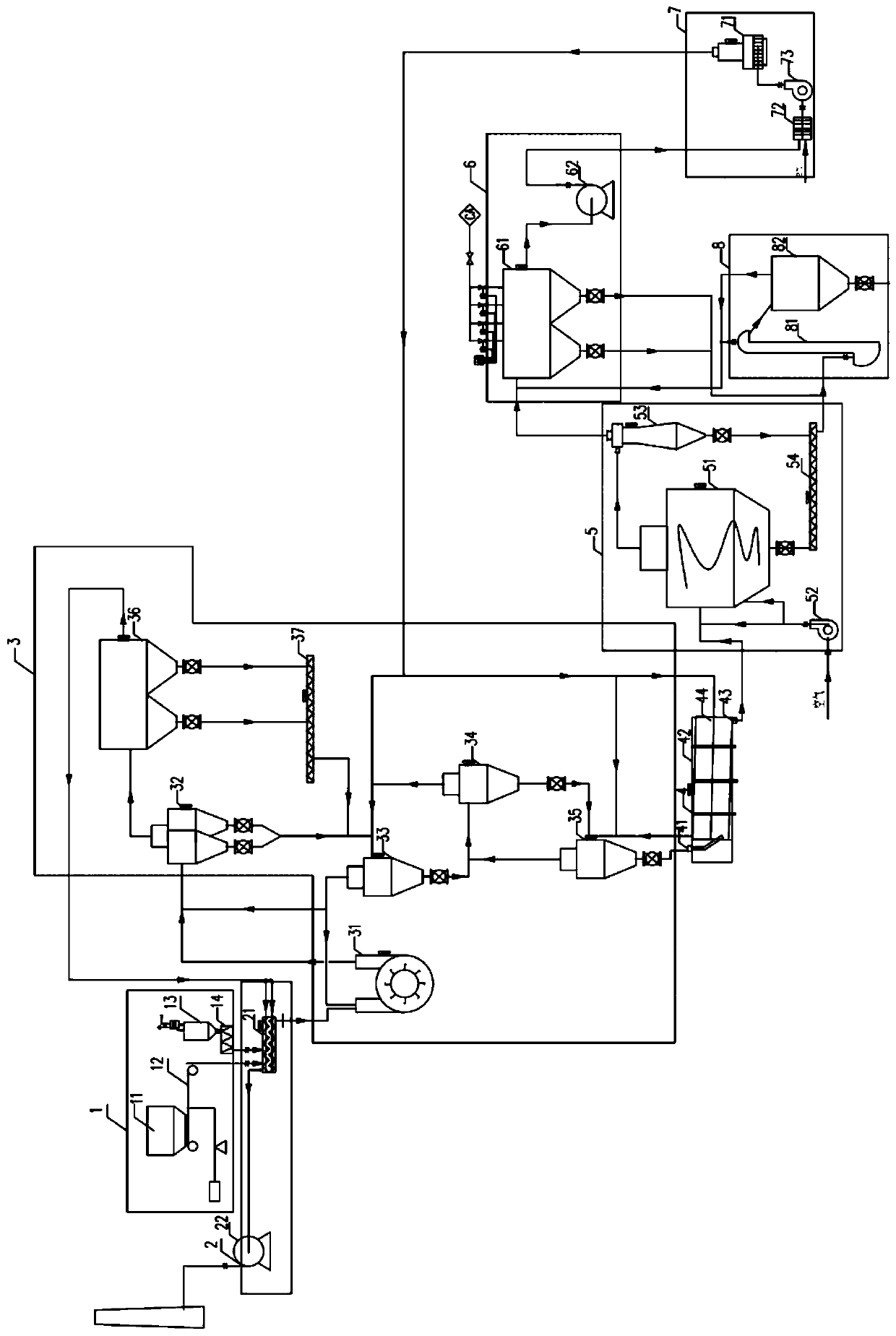

[0089] This embodiment provides a device for producing type II anhydrite from phosphogypsum, the structural connection schematic diagram of the device is as follows figure 1 As shown, it includes a pretreatment unit 2, a drying unit 3, a calcining unit 4 and a product collection unit 8 connected in sequence, the pretreatment unit 2 includes a spiral stirring device 21, and the drying unit 3 includes a breaking device 31 and at least one A drying device, the calcining unit 4 includes a calcining device 42, and a heat source pipeline is arranged in the calcining device 42.

[0090] The helical stirring device 21 comprises a double-helical stirrer, the double-helical stirrer is provided with a stirring paddle, and the stirring paddle is an internal hollow structure; the upper part of the spiral stirring device 21 is provided with a moisture outlet, and the lower part is also provided with a There is a supplementary air port; the pretreatment unit 2 also includes a first induced d...

Embodiment 2

[0100] This embodiment provides a device for producing type II anhydrite from phosphogypsum. The structure of the device refers to the structure in embodiment 1, the difference is that the drying device of the drying unit 3 includes two stages, two stages of drying The solid outlet of the device 33 is connected to the calcining unit 4; the calcining device 42 is inclined downward from the inlet to the outlet, with a gradient of 1.5%.

Embodiment 3

[0106] This embodiment provides a method for producing Type II anhydrite from phosphogypsum, said method is carried out using the device in Example 1, comprising the following steps:

[0107] (1) react after mixing phosphogypsum and calcium oxide, the content of free hydrogen ion in the phosphogypsum satisfies the pH value of 3, the content of soluble phosphate is 1.4wt%, the content of soluble fluorine is 0.75wt%, and the content of free water accounts for 20wt% of the total amount of phosphogypsum, the grade of phosphogypsum is 92%, the mass ratio of said phosphogypsum to calcium oxide is 17500:1, and the temperature of said reaction is 60°C;

[0108] (2) Dispersing and drying the product obtained in step (1), the average particle size of the raw material after disintegration is 35 μm, the number of drying stages is 4, and the temperature of the next stage of drying is higher than that of the previous stage of drying The temperature of dispersing and drying at different leve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com