Method for reinforcing recycled aggregates through biological carbonization

A recycled aggregate and biological technology, applied in the field of recycled aggregate reinforcement, can solve the problems of restricting the reuse of recycled aggregate, high crushing index, and high porosity, and achieves the improvement of hydration reaction rate, quality and water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

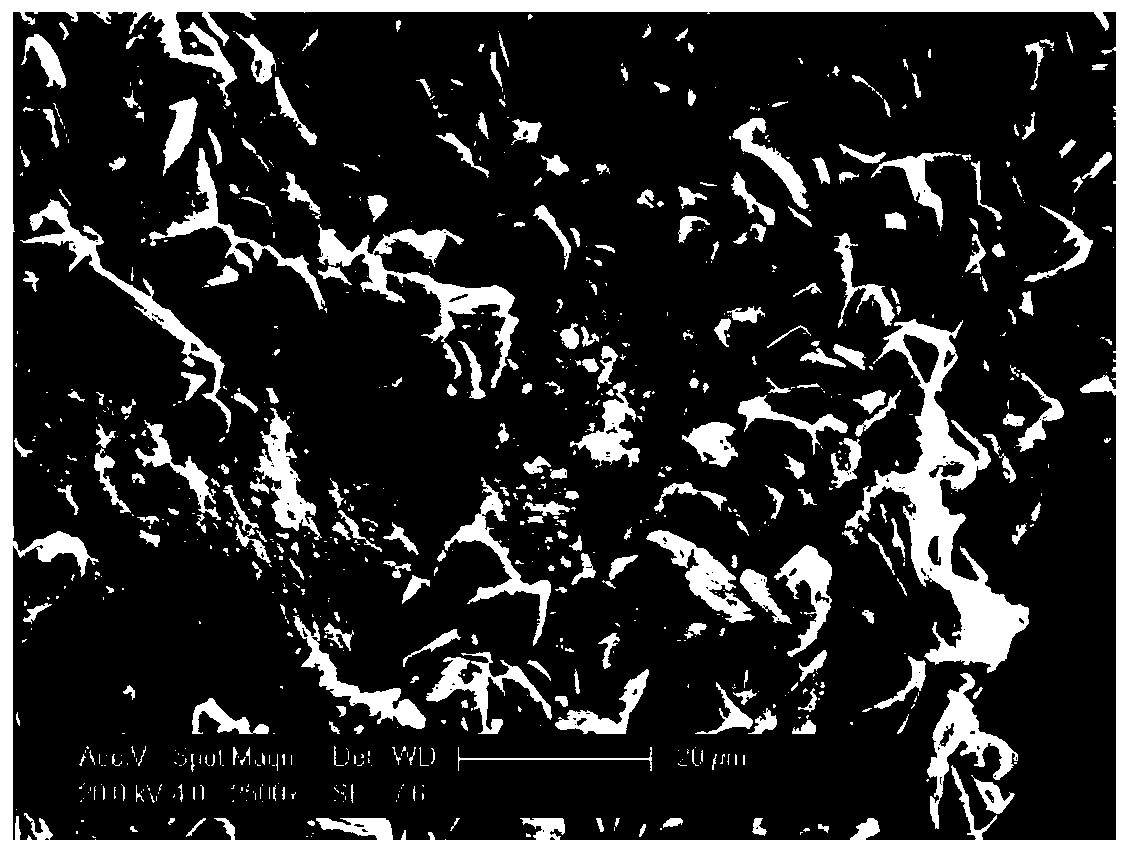

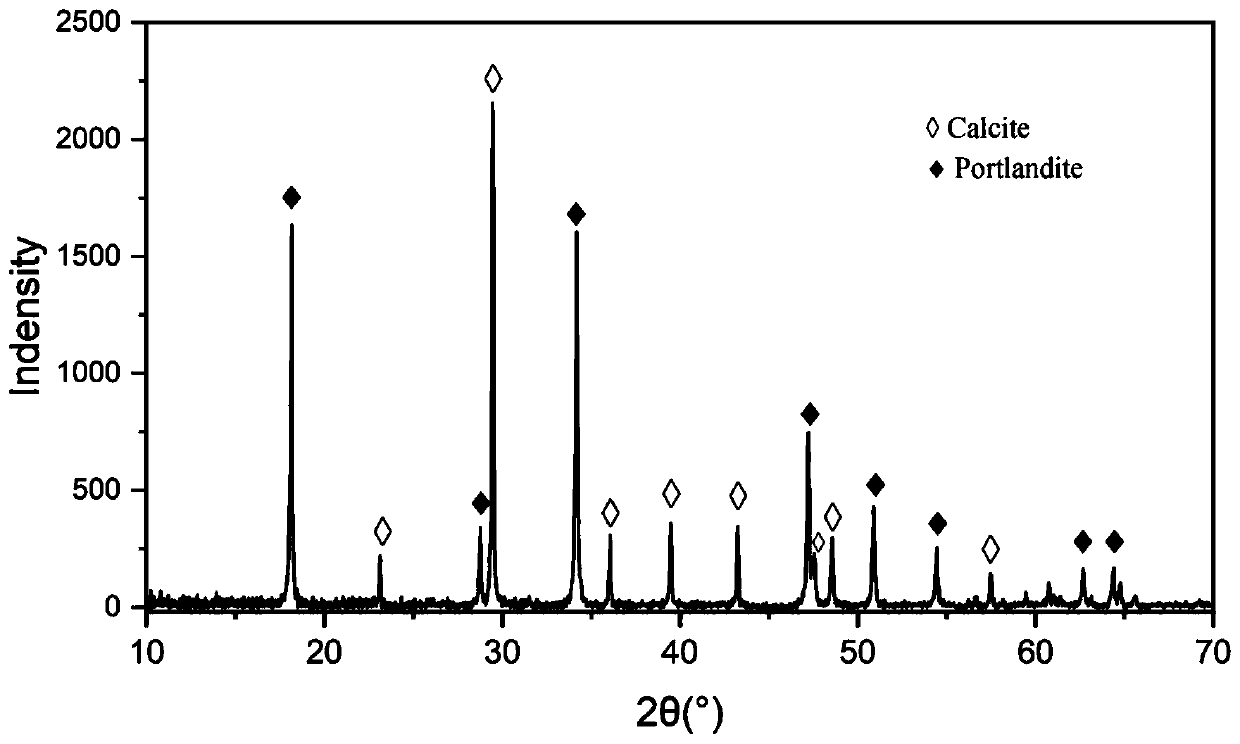

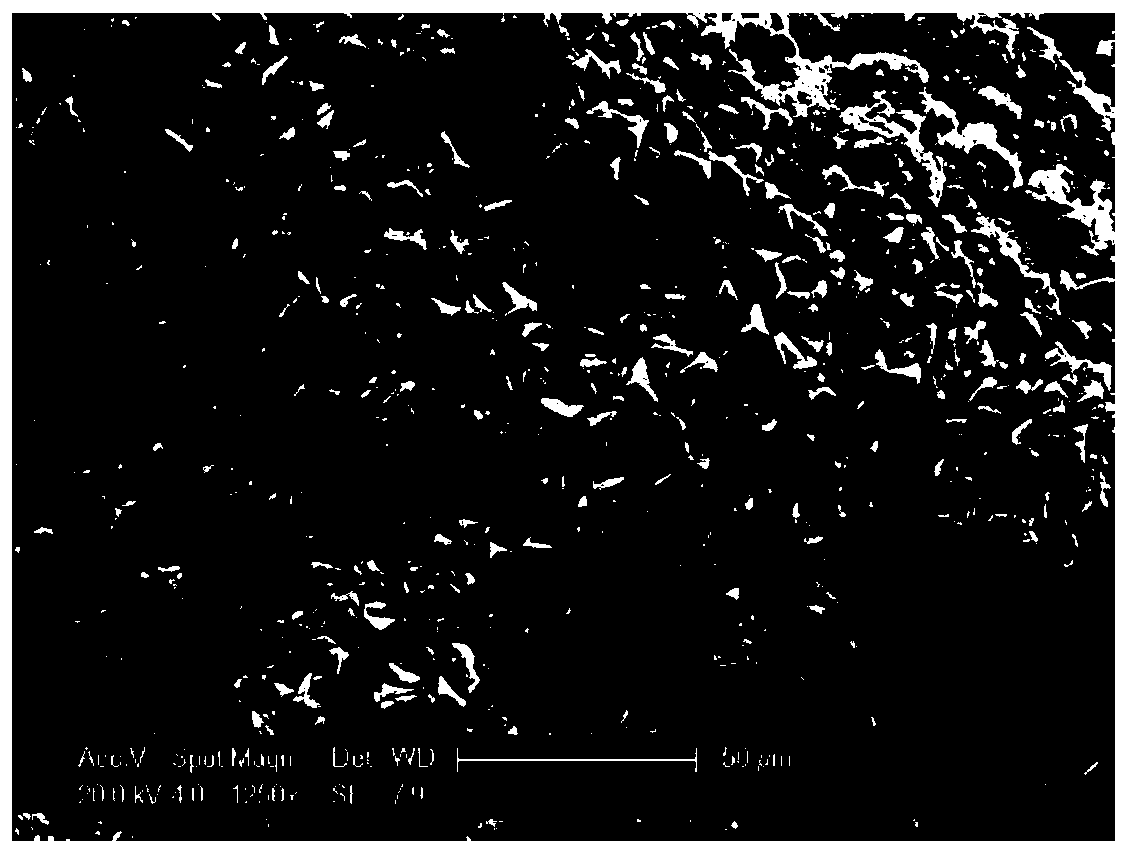

Image

Examples

Embodiment 1

[0027] Embodiment 1: A kind of method of biological carbonization strengthening recycled aggregate, the steps are as follows:

[0028] (1) collect recycled aggregate, prepare calcium hydroxide solution, concentration is 0.02mol;

[0029] (2) Obtain the Bacillus colloidus bacterium liquid: Inoculate the Bacillus colloidus into the culture medium solution after sterilization, every liter of medium contains sucrose 9g, Na 2 HPO 4 12H 2 O2g, MgSO 4 0.5g, CaCO 3 1.0g, KCl0.1g, (NH 4 ) 2 SO 4 0.4g, 0.4g of yeast extract powder, and control the pH to 7, shake culture at 30°C for 24 hours to obtain the bacterial liquid containing Bacillus colioids;

[0030] (3) Carry out carbonization strengthening treatment: spray calcium hydroxide solution and colloidal bacillus bacteria solution on the surface of the recycled aggregate successively until the surface of the aggregate is wet, once every 6 hours, repeat 3 times, put the aggregate after spraying In a closed container or curing ...

Embodiment 2

[0032] Embodiment 2: A kind of method of biological carbonization strengthening recycled aggregate, the steps are as follows:

[0033] (1) collect recycled aggregate, prepare calcium chloride solution, concentration is 1.00mol;

[0034] (2) Obtain the Bacillus colloidus bacterium liquid: inoculate the Bacillus colloidus into the culture medium solution after sterilization, every liter of medium contains sucrose 12g, Na 2 HPO 4 12H 2 O3g, MgSO 4 0.6g, CaCO 3 1.5g, KCl0.2g, (NH 4 ) 2 SO 4 0.4g, 0.4g of yeast extract powder, and control the pH to 9, shake culture at 37°C for 24h to obtain the bacterial liquid containing Bacillus colioids;

[0035] (3) Carry out carbonization strengthening treatment: spray calcium hydroxide solution and colloidal bacillus bacteria solution on the surface of the recycled aggregate successively until the surface of the aggregate is wet, once every 6 hours, repeat 5 times, put the aggregate after spraying In a closed container or curing room,...

Embodiment 3

[0037] Embodiment 3: A kind of method of biological carbonization strengthening recycled aggregate, the steps are as follows:

[0038] (1) collect recycled aggregate, prepare calcium acetate solution, concentration is 0.50mol;

[0039] (2) Obtain the Bacillus colloidus bacterium liquid: inoculate the Bacillus colloidus into the culture medium solution after sterilization, every liter of medium contains sucrose 8g, Na 2 HPO 4 12H 2 O2g, MgSO 4 0.4g, CaCO 3 0.5g, KCl0.1g, (NH 4 ) 2SO 4 0.4g, 0.2g of yeast extract powder, and control the pH to 8, shake culture at 37°C for 24h to obtain the bacterial liquid containing Bacillus colioids;

[0040] (3) Carry out carbonization strengthening treatment: spray calcium hydroxide solution and colloidal bacillus bacteria solution on the surface of the recycled aggregate successively until the surface of the aggregate is wet, once every 6 hours, repeat twice, and put the aggregate after spraying In a closed container or curing room, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com