Silicon recovery method

A technology of silicon raw material and sodium silicate is applied in the field of solid waste resource utilization to achieve the effects of expanding application channels, high recovery rate and less residue.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

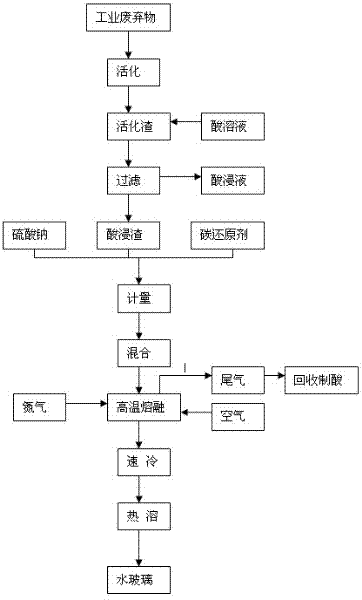

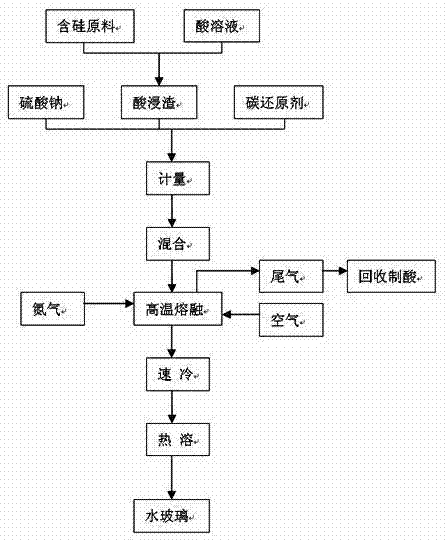

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1: the method for this recovery silicon, concrete operation is as follows:

[0028] Using fly ash as raw material, take 200g of fly ash and put it into a 1000ml three-neck flask, add 600g of sulfuric acid solution with a mass percentage concentration of 65%, that is, the liquid-solid ratio is 3:1, react at 115°C for 4h, filter, water Wash until the pH is 3 to obtain 137g of acid leaching residue. After analysis, the SiO in the acid leaching residue 2 、Al 2 o 3 , TFe, Ca0, MgO, SO 3 The contents are 85.55%, 3.22%, 1.35%, 3.45%, 0.10%, 5.45%, respectively.

[0029] Take 50g of the above acid leaching residue, use high-sulfur coal as a reducing agent (the fixed carbon content of high-sulfur coal is 72%, and the elemental sulfur content is 4.32%) to prepare sodium silicate with a modulus of 1.0. According to the overall reaction equation, anhydrous The amount of sodium sulfate and high-sulfur coal added is 95g and 5.7g respectively. After the raw materials a...

Embodiment 2

[0030] Embodiment 2: the method for this recovery silicon, concrete operation is as follows:

[0031] Coal gangue is used as raw material. Coal gangue is thermally activated at 750°C for 2 hours, and ground until the particle size is less than 5% after passing through an 80-mesh sieve. Take 200g of activated coal gangue and put it into a 1000ml three-necked flask, and add a mass percentage concentration of 60 % sulfuric acid solution 800g, that is, the liquid-solid ratio is 4:1, react at 110°C for 3h, filter, wash with water until the pH is 4, and obtain 125g of acid leaching residue. After analysis, the SiO in the acid leaching residue 2 、Al 2o 3 , TFe, Ca0, MgO, SO 3 The contents are 91.37%, 1.30%, 0.33%, 2.85%, 0.01%, 3.97%, respectively.

[0032] Take 50g of the above acid leaching residue, use high-sulfur coal as a reducing agent (the fixed carbon content of high-sulfur coal is 72%, and the elemental sulfur content is 4.32%) to prepare sodium silicate with a modulus o...

Embodiment 3

[0033] Embodiment 3: the method for this recovery silicon, concrete operation is as follows:

[0034] Use bauxite beneficiation tailings as raw material, heat-activate the tailings at 800°C for 1.5 hours, grind until the particle size is less than 5% after passing through an 80-mesh sieve, take 200g of activated tailings and put them into a 1000ml three-neck flask, add mass The percentage concentration is 700g of 30% hydrochloric acid solution, that is, the liquid-solid ratio is 3.5:1, react at 95°C for 3.5h, filter, wash with water until the pH is 3.5, and obtain 122g of acid leaching residue. After analysis, the SiO in the acid leaching residue 2 、Al 2 o 3 , TFe, Ca0, MgO, SO 3 The contents are 93.20%, 1.22%, 0.21%, 2.02%, 0.03%, 3.17%, respectively.

[0035] Take 50g of the above-mentioned acid leaching residue, and use ordinary coal as raw material (fixed carbon content is 83.6) to prepare sodium silicate with a modulus of 3.5. According to the overall reaction equatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com