Method for casting multi-box hot pot

A multi-format, hot pot technology, applied in the field of iron pot casting, can solve the problems of difficult movement of the pot body, change of taste of the hot pot, and easy-to-corrosion compartments, etc., to reduce the risk of fragility, slow down the heat dissipation speed, and improve the heat conduction effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

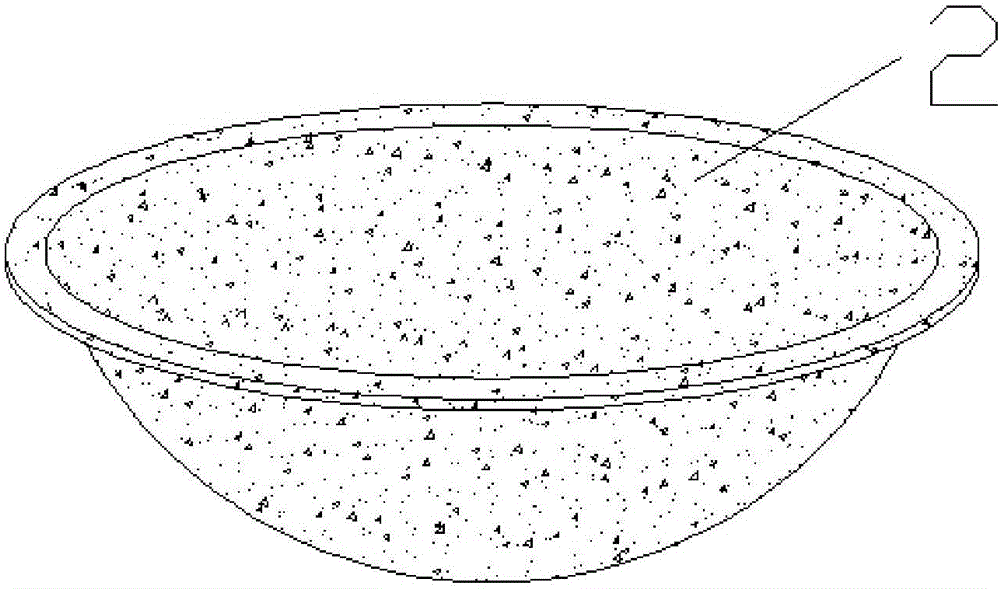

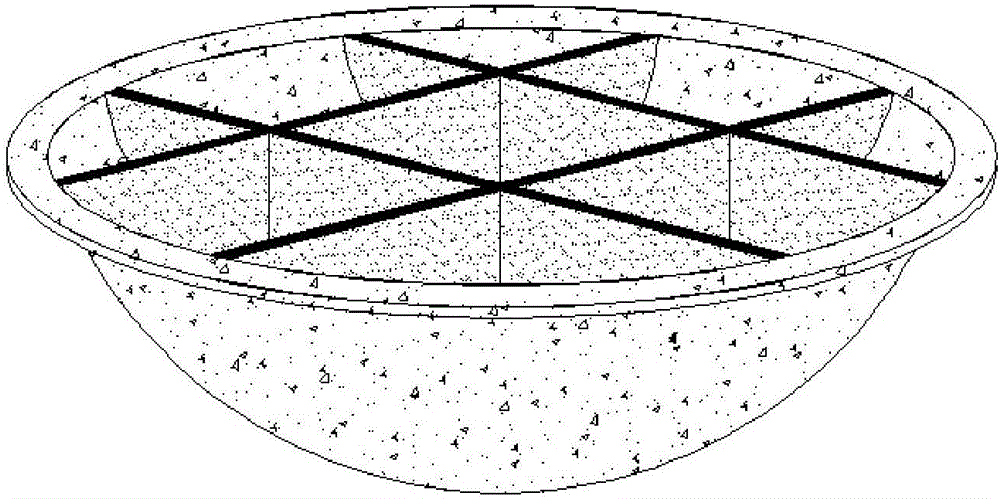

[0035] A casting method for a multi-format hot pot pot, the hot pot pot includes a pot body and a partition arranged inside the pot and connected to the pot body, the partition divides the inner space of the pot into at least two compartments, the Described casting method comprises the following steps:

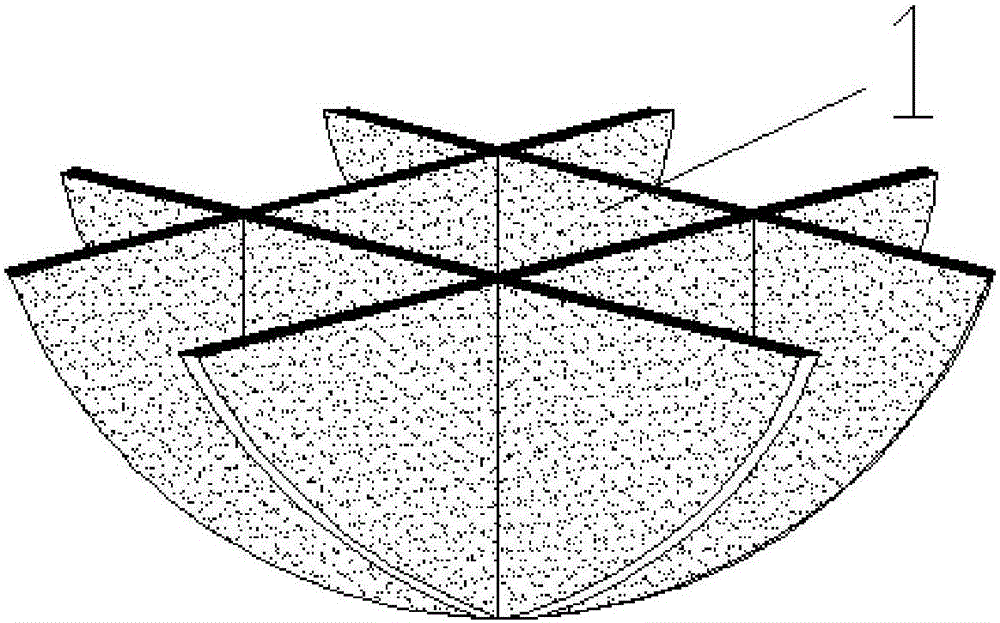

[0036] (1) Forming of the clapboard: select a well-shaped clapboard mold, and a gap corresponding to the shape and size of the well-shaped clapboard is provided in the clapboard mold, and the molten cast iron is slowly introduced into the gap until the molten iron Just overflowing the mould, the molten iron is cooled and formed and then taken out to obtain the separator, as figure 1 and Figure 5 shown;

[0037] (2) Partition plate is molded and polished: select the upper pot mold, the outer surface of the upper pot mold matches the inner surface structure of the pot main body, and the center of the bottom of the upper pot mold is provided with a well-shaped partition that c...

Embodiment 2

[0042] A casting method for a multi-format hot pot pot. The hot pot pot includes a pot body and a partition arranged inside the pot and connected to the pot body. The partition divides the inner space of the pot into two compartments. The casting method includes the following steps:

[0043] (1) Forming of the partition: select an S-shaped partition mold, and a gap corresponding to the shape and size of the S-shaped partition is provided in the partition mold, and the molten cast iron is slowly introduced into the gap until the molten iron Just until it overflows the mould, the molten iron is cooled and formed and then taken out to obtain the separator;

[0044] (2) Partition plate is molded and polished: select the upper pot mold, the outer surface of the upper pot mold matches the inner surface structure of the pot main body, and the center of the bottom of the upper pot mold is provided with an S-shaped partition that can only accommodate the obtained step (1). The gap, th...

Embodiment 3

[0049] A casting method for a multi-format hot pot pot, the hot pot pot includes a pot body and a partition arranged inside the pot and connected to the pot body, the partition divides the inner space of the pot into four compartments, the The casting method includes the following steps:

[0050] (1) Forming of the clapboard: use a cross-shaped clapboard mold, which is provided with a gap corresponding to the shape and size of the cross-shaped clapboard, and slowly introduce molten cast iron into the gap until the molten iron Just until it overflows the mould, the molten iron is cooled and formed and then taken out to obtain the separator;

[0051] (2) Partition plate is molded and polished: select the upper pot mold, the outer surface of the upper pot mold matches the inner surface structure of the pot main body, and the bottom center of the upper pot mold is provided with a cross-shaped partition that can only accommodate the obtained step (1). The gap, the shape of the gap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com