Patents

Literature

76results about How to "Fully fused" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

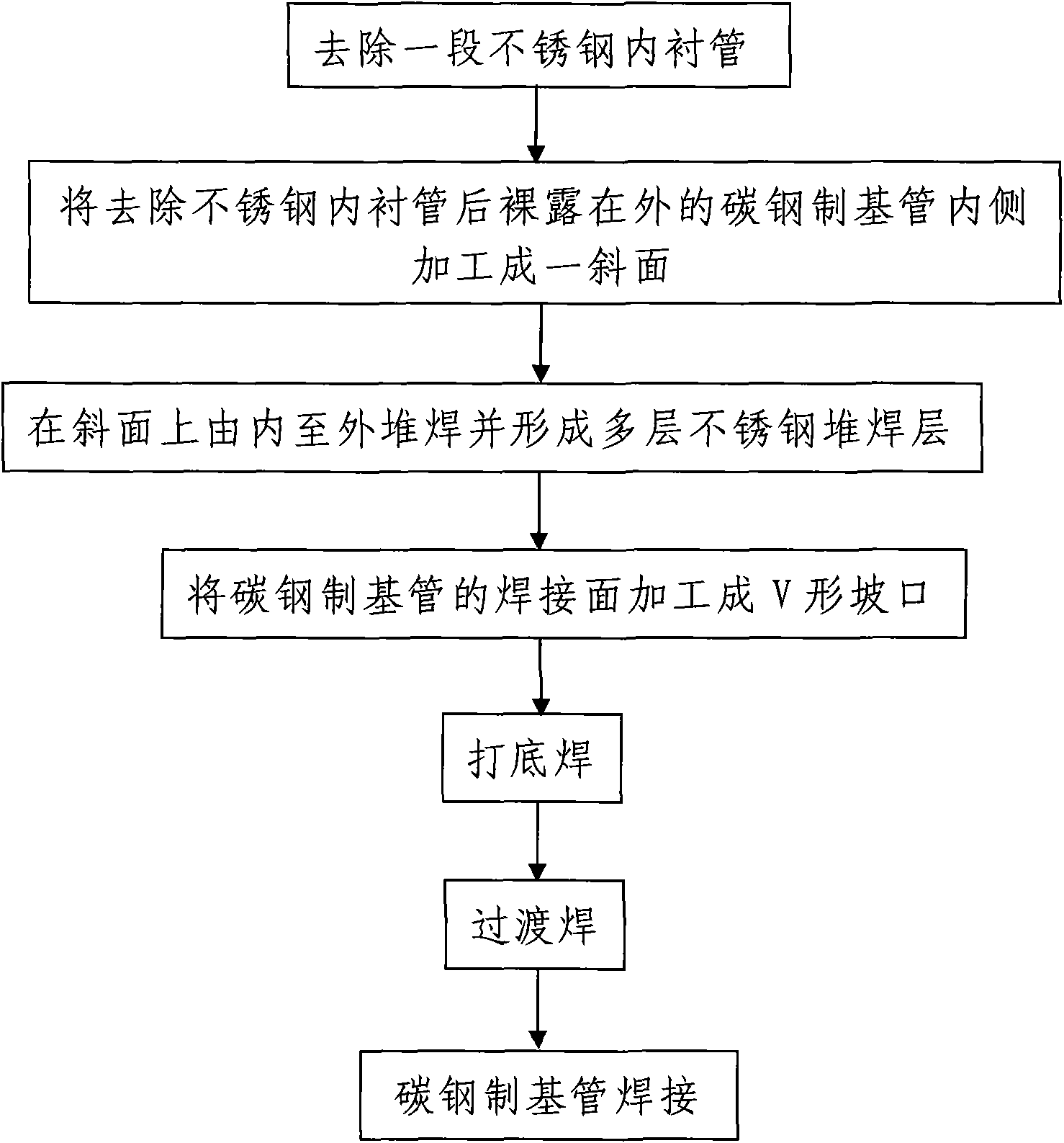

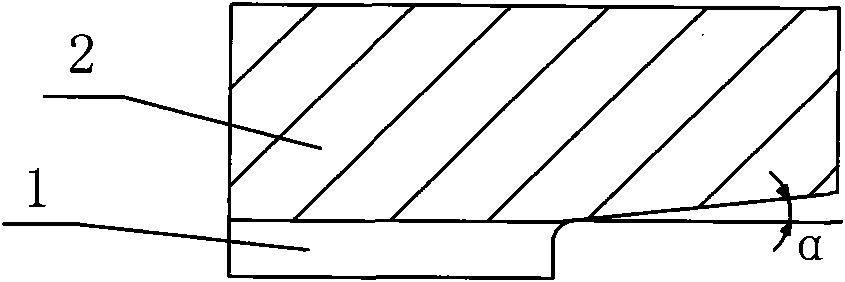

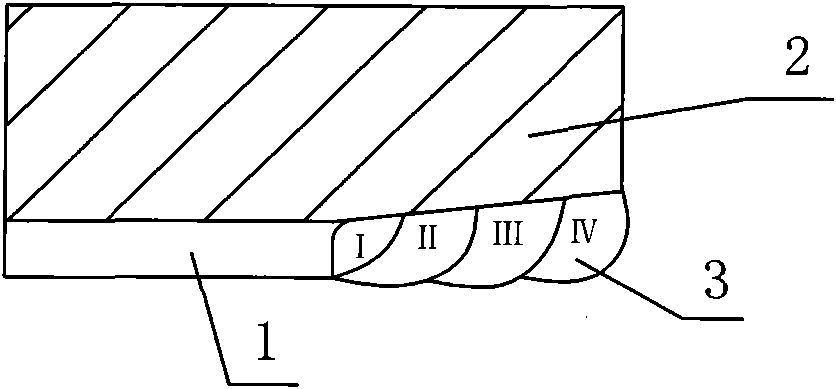

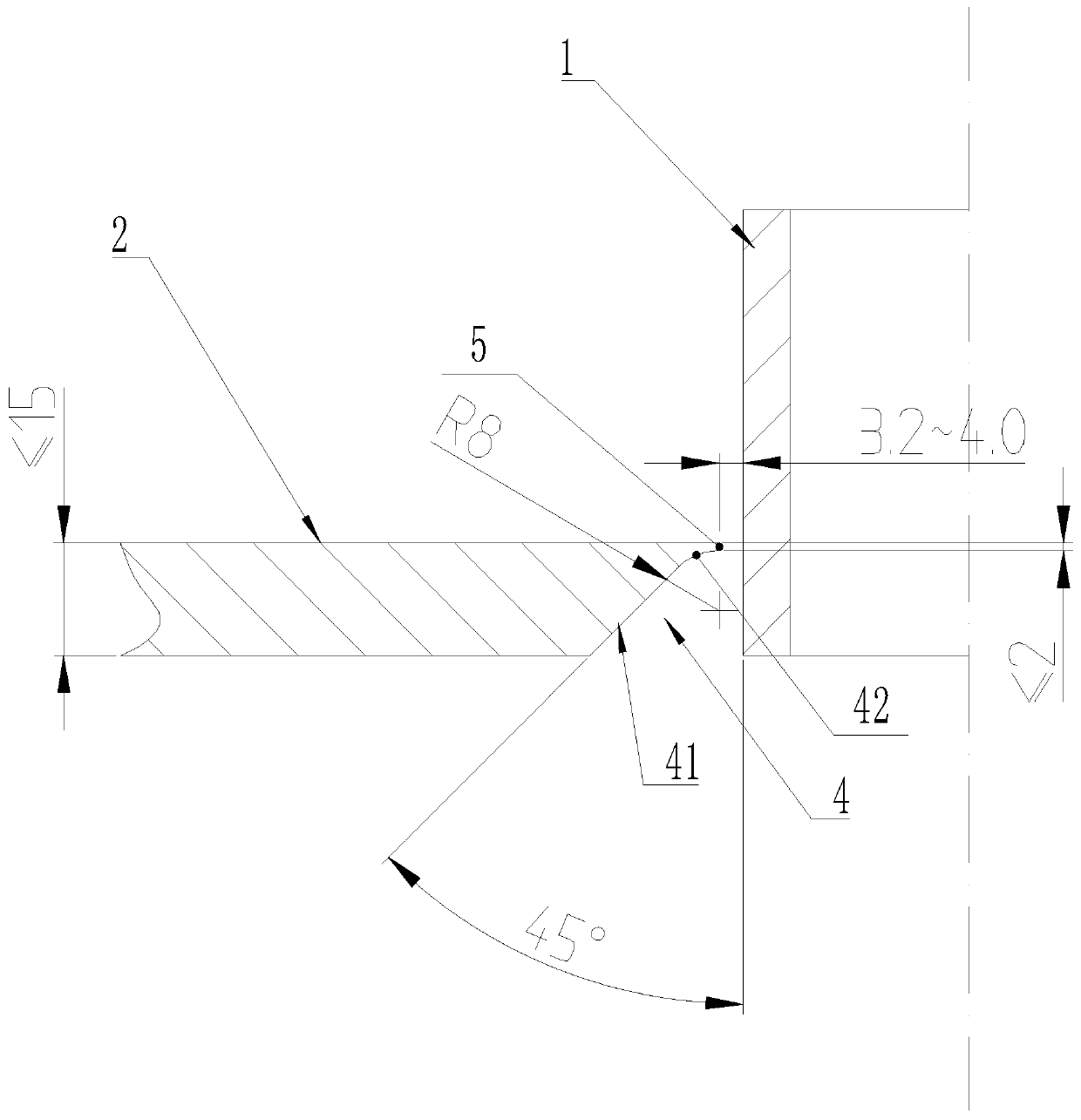

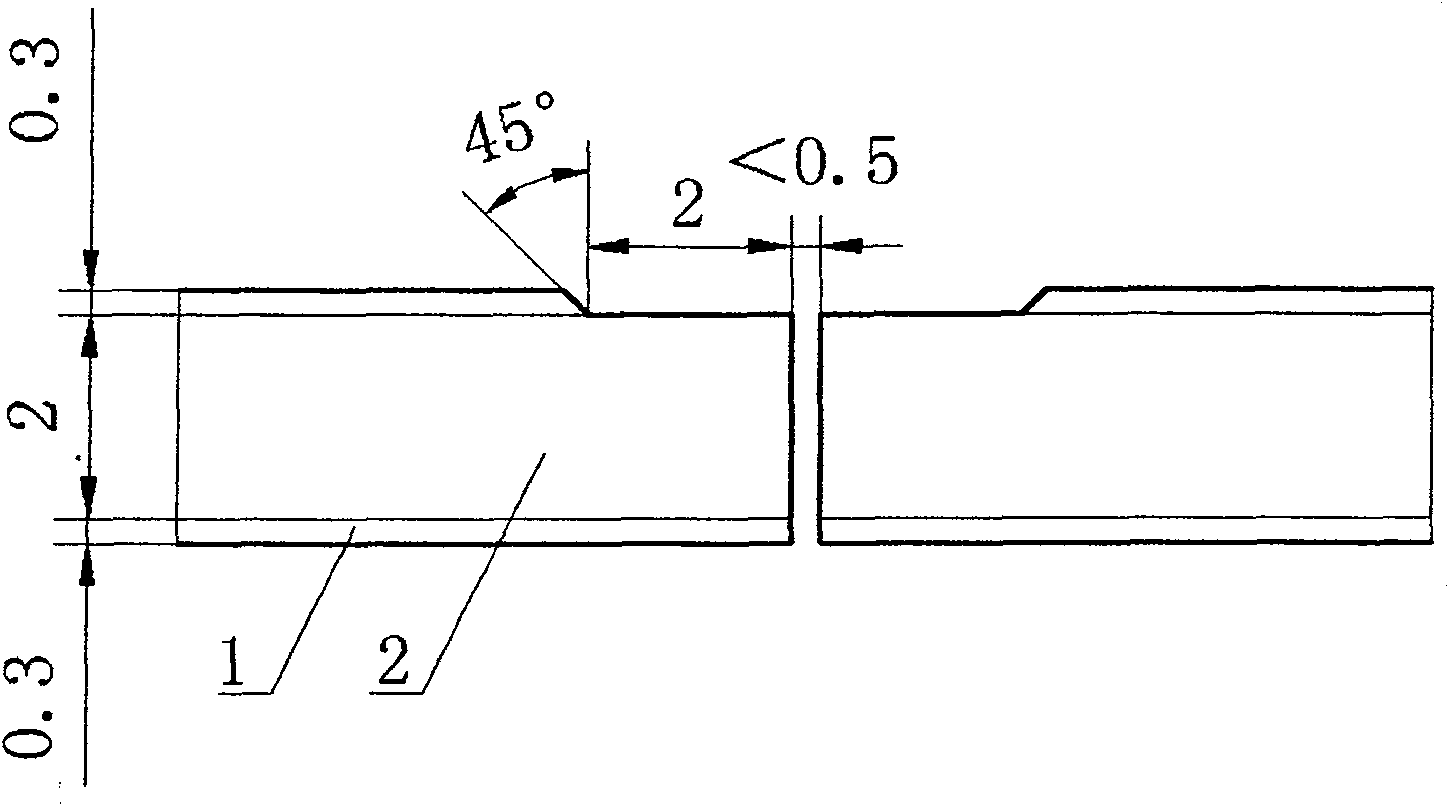

Method for welding composited tube at bonding interface of carbon steel/stainless steel machinery

ActiveCN101653855ASimple welding processExcellent weld mechanical properties and corrosion resistanceArc welding apparatusWelding/cutting media/materialsCarbon steelArc welding

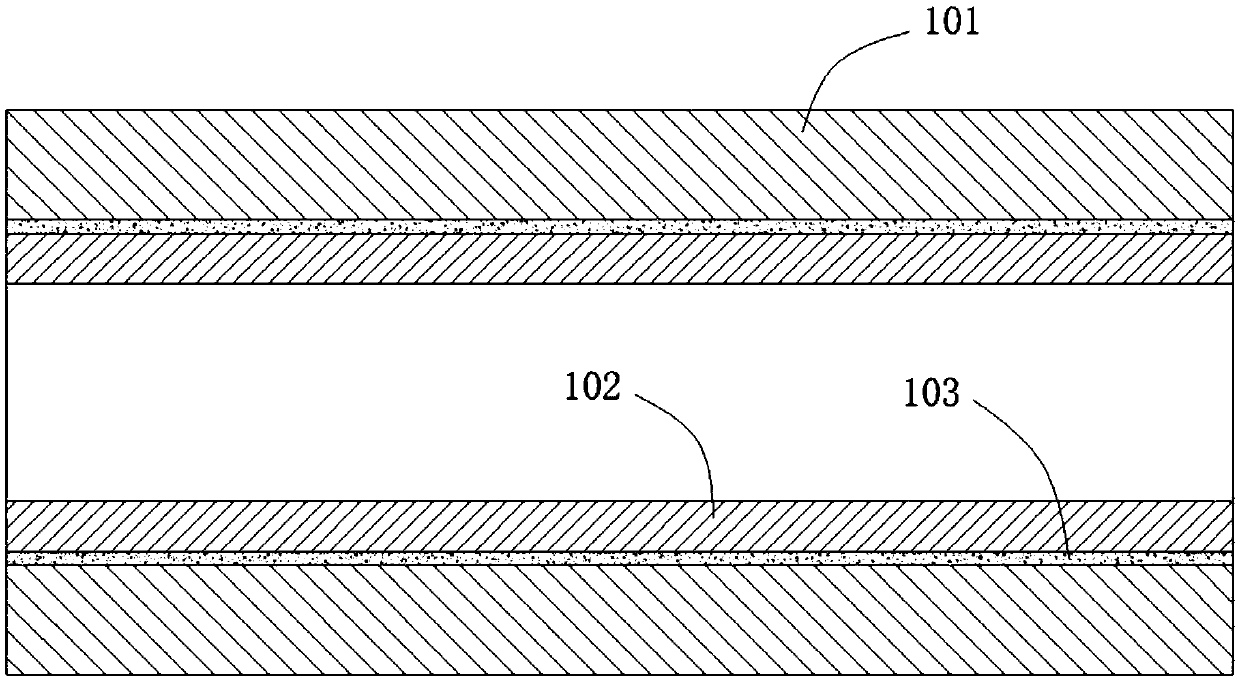

The invention discloses a method for welding composited tube at the bonding interface of carbon steel / stainless steel machinery, comprising the following steps: 1. welding groove treatment as follows:removing a section of stainless steel lined tube; processing the interior of the carbon steel parent tube exposed outside after removing the stainless steel lined tube into an inclined plane inclinedinwards from exterior to interior; using a tungsten electrode argon arc welding machine to carry out bead weld on the inclined plane from interior to exterior and forming multiple stainless steel bead weld layers; processing the weld surface of the carbon steel parent tube into a V-shaped groove; 2. backing weld: when fitting up the stainless steel bead weld layers before backing weld, adopting the tungsten electrode argon arc welding machine to carry out fitting-up and fixing in a manner of spot welding; 3. transition weld; and 4. carbon steel parent tube weld. The invention features simpleprocedure steps, less used weld materials, high weld pass percentage, good welding line mechanical property, high weld quality and improved production efficiency simultaneously.

Owner:XIAN SUNWARD AEROSPACE MATERIAL

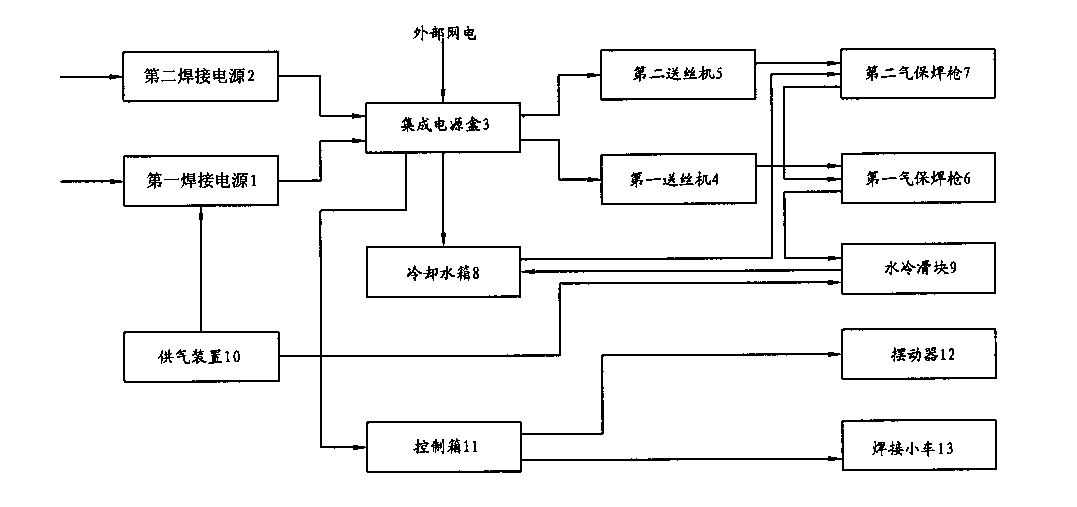

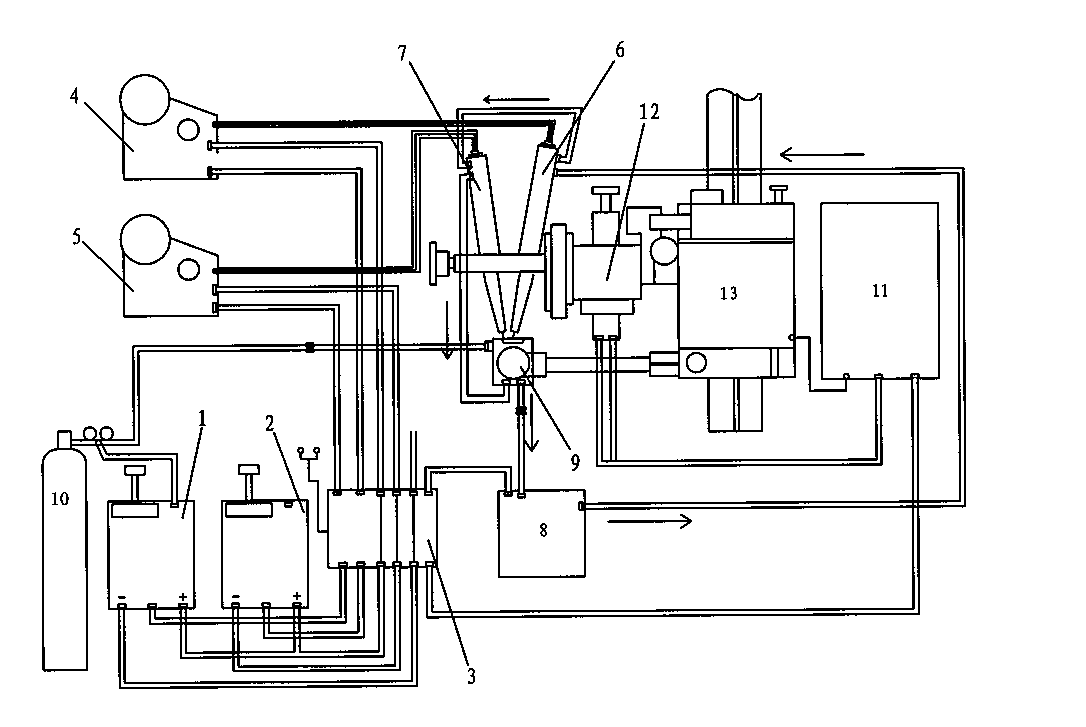

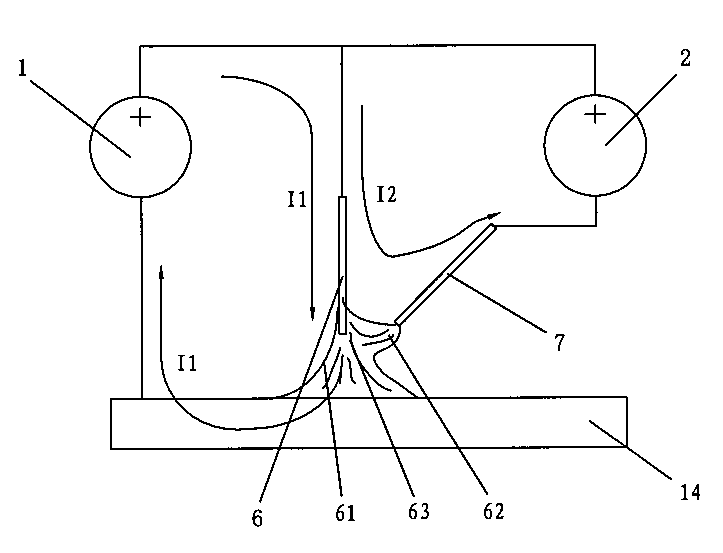

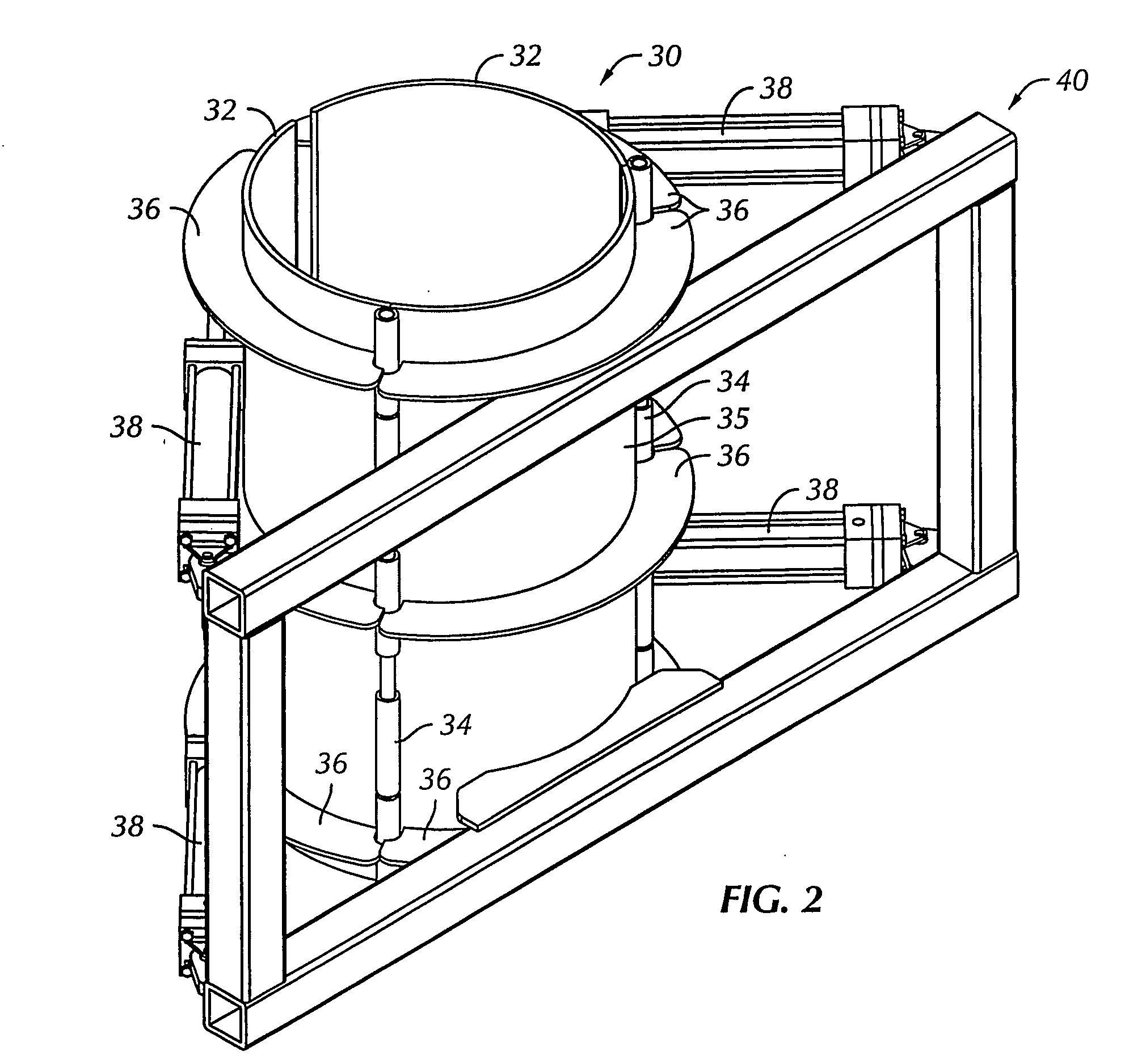

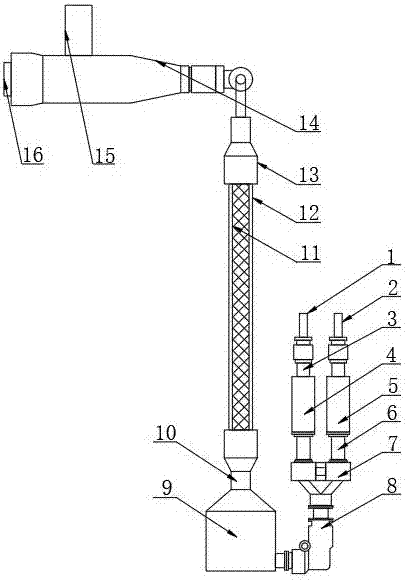

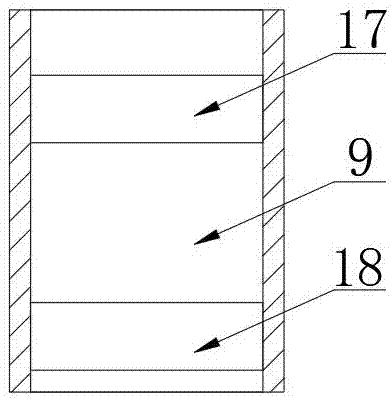

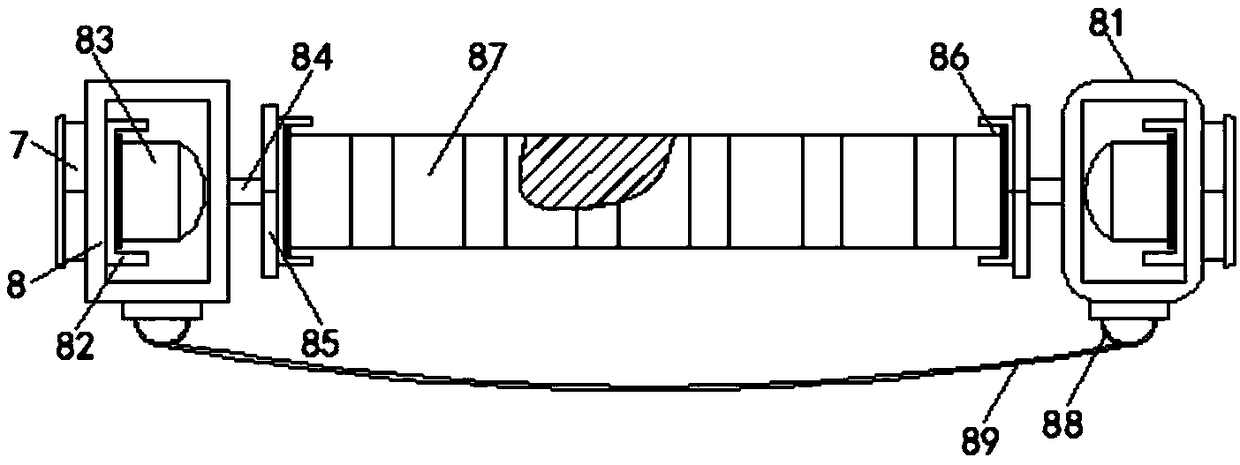

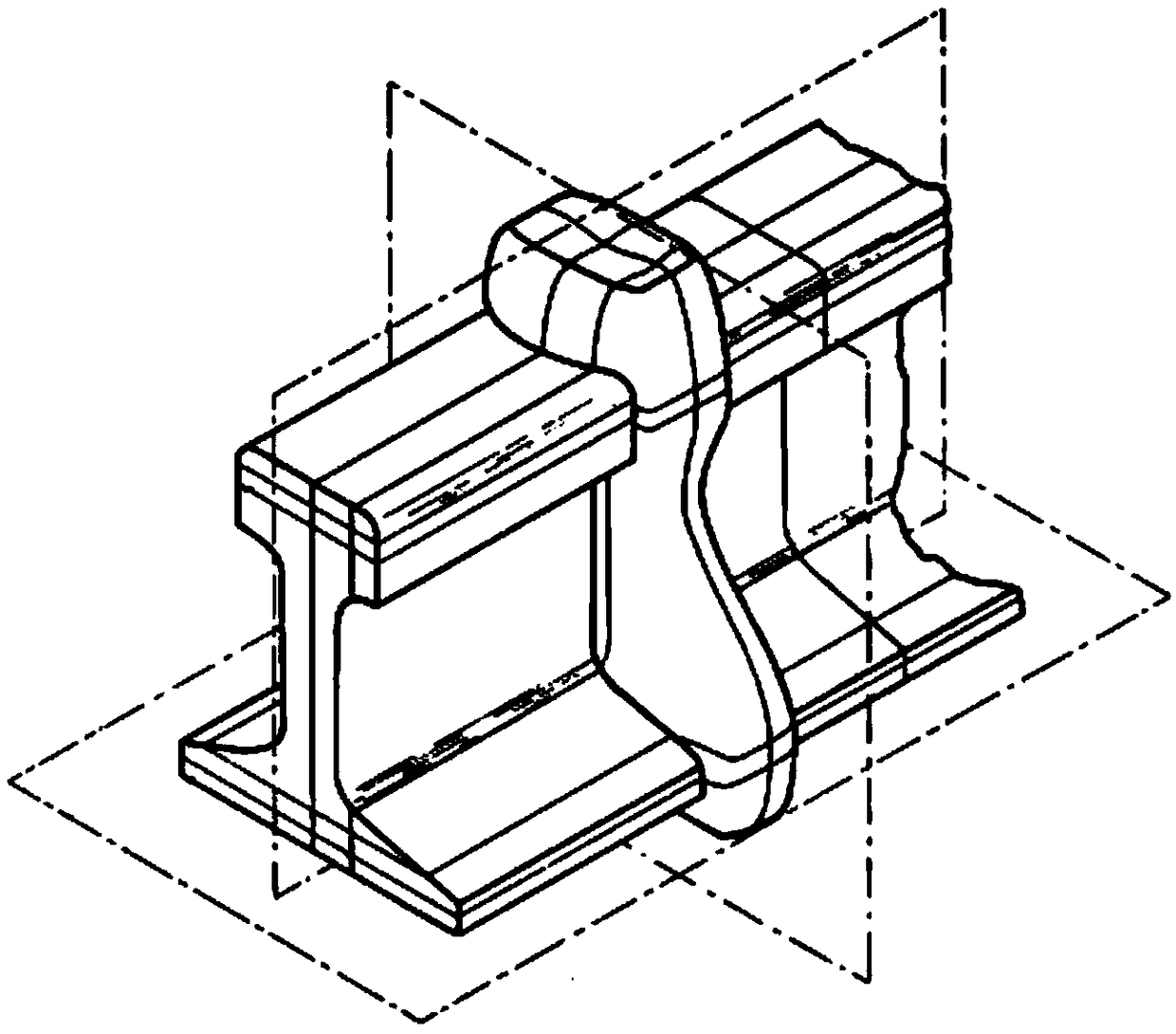

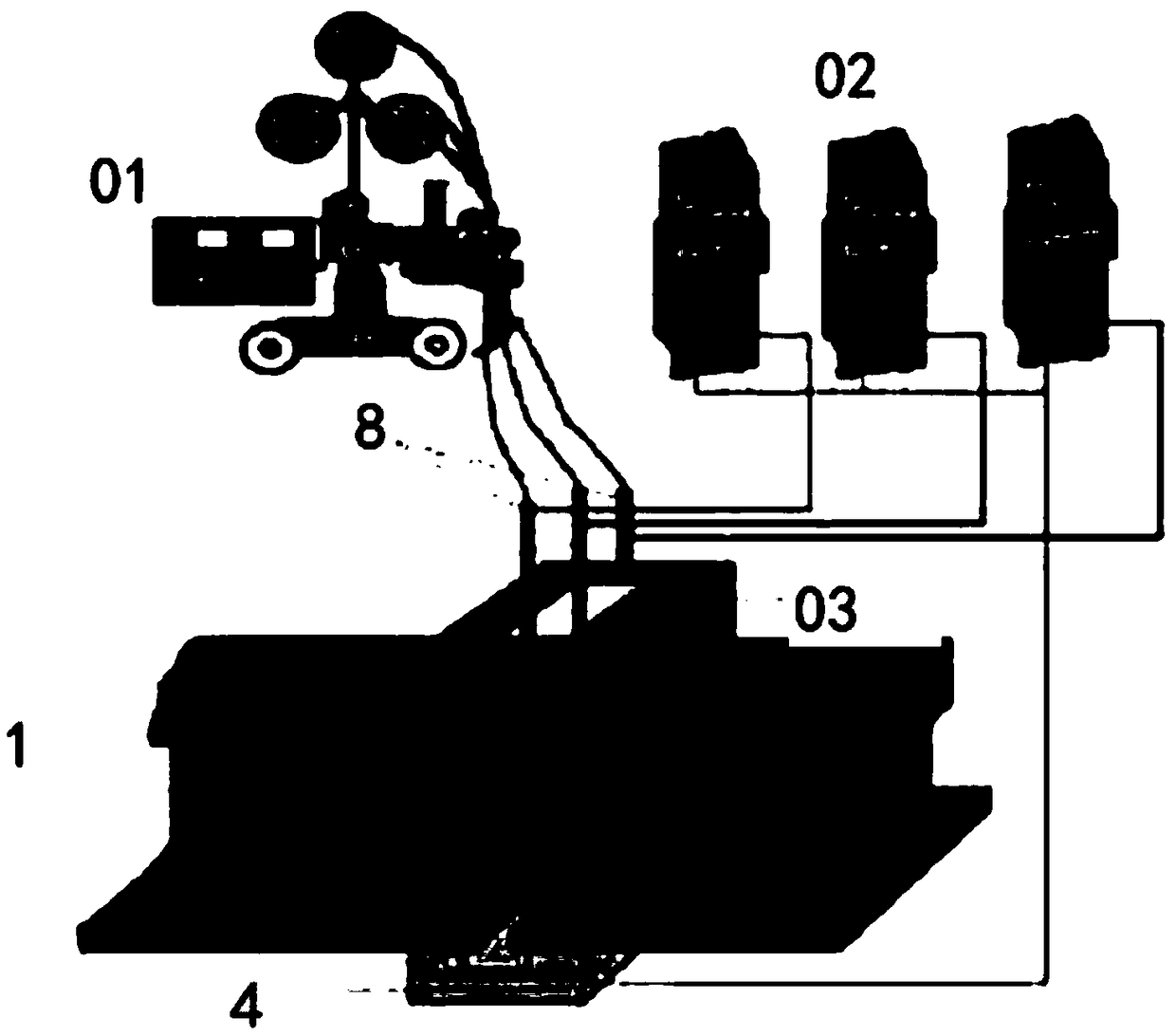

Twin-wire vertical electrogas welding system with low welding heat input and welding method

The invention provides a twin-wire vertical electrogas welding system with low welding heat input and a welding method. The system comprises a first welding power source, a second welding power source, an integrated power source box, a first wire feeder, a second wire feeder, a first gas shielded welding gun, a second gas shielded welding gun, a gas supply device, a control cabinet, an oscillator and a welding tractor, wherein homopolar output ends of the first welding power source and the second welding power source are in conductive connection with a head end of the first gas shielded welding gun, the other output end of the first welding power source is connected with a welded workpiece, and the other output end of the second welding power source is in conductive connection with a head end of the second gas shielded welding gun, so that heat input is greatly reduced while deposition rate can be increased, the system is stable and reliable, and impact toughness of a welding line is remarkably improved. Additionally, a twin-wire welding gun oscillating in the welding line can guarantee sufficient fusion of side walls of the welding line and a welding weld crater, so that mechanical properties of the welding line are remarkably enhanced.

Owner:SHENZHEN RILAND IND

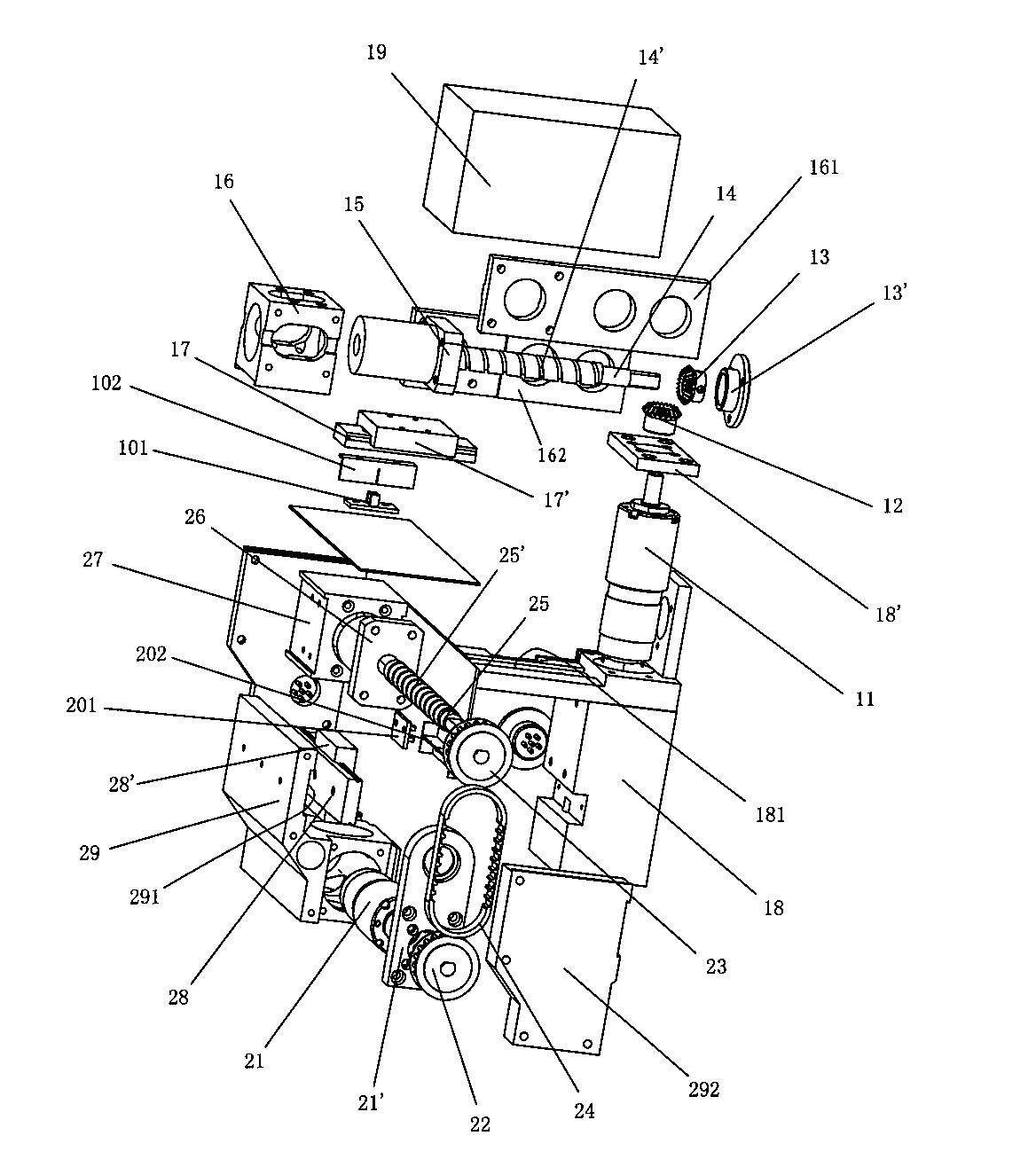

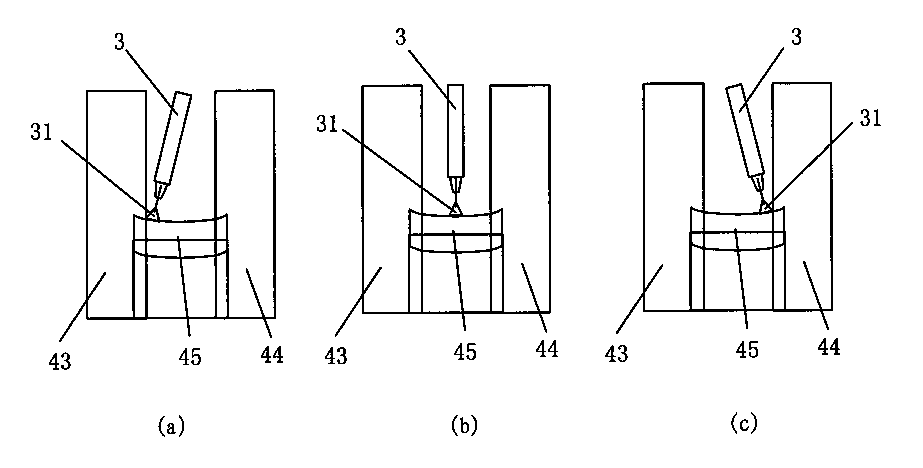

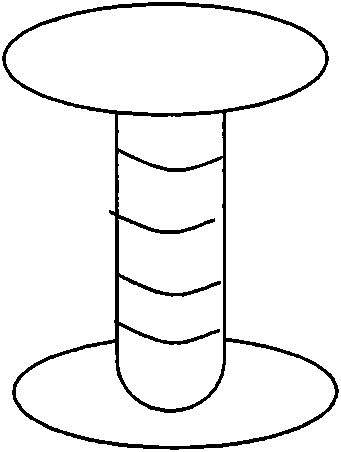

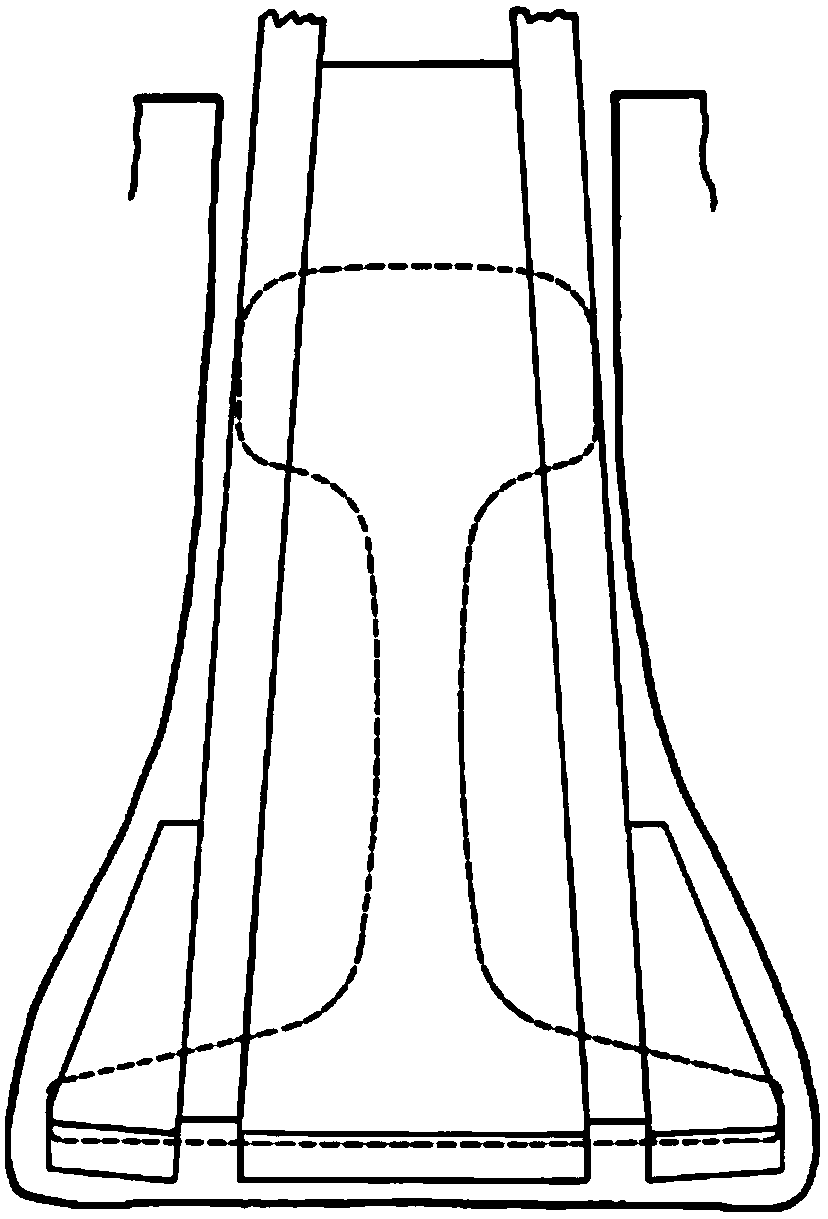

Welding gun swinging device for vertical electrogas welder

ActiveCN102423827AStrong penetrating powerImprove mechanical propertiesArc welding apparatusLinear motionReciprocating motion

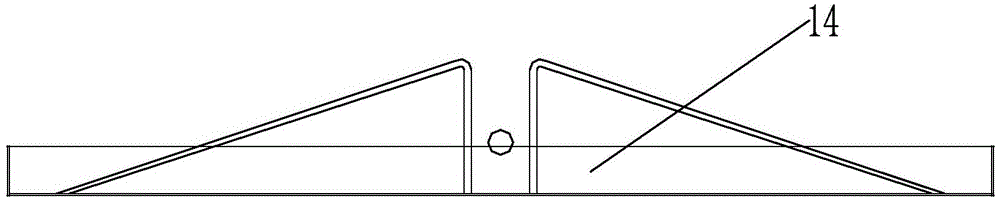

The invention provides a welding gun swinging device for a vertical electrogas welder, which comprises a horizontal sliding mechanism for leading a welding gun to carry out linear motion along the direction of a vertical weld seam and a serrated swinging mechanism for leading the welding gun to swing in a groove clearance of the vertical electrogas welder, wherein the serrated swinging mechanism on which the welding gun is mounted is arranged on the horizontal sliding mechanism. Thus, the invention has the beneficial effects that a welding electric arc can move back and forth and be welded between a forming cushion plate on the back surface of the weld seam and a water-cooled forming slide block on the front surface of the weld seam as well as between a left side plate and a right side plate of a groove of the vertical electrogas welder; the side wall of the weld seam can be effectively ensured to be fully fused with a welding pool; the depth of a weld penetration can be remarkably increased, so that the mechanical property of the weld seam can be remarkably improved; and even if the melting speed of a welding wire is improved and the welding heat input is reduced, the side wall of the weld seam can still be fully fused with the welding pool to avoid interruption or mutation, even crack.

Owner:SHENZHEN RILAND IND

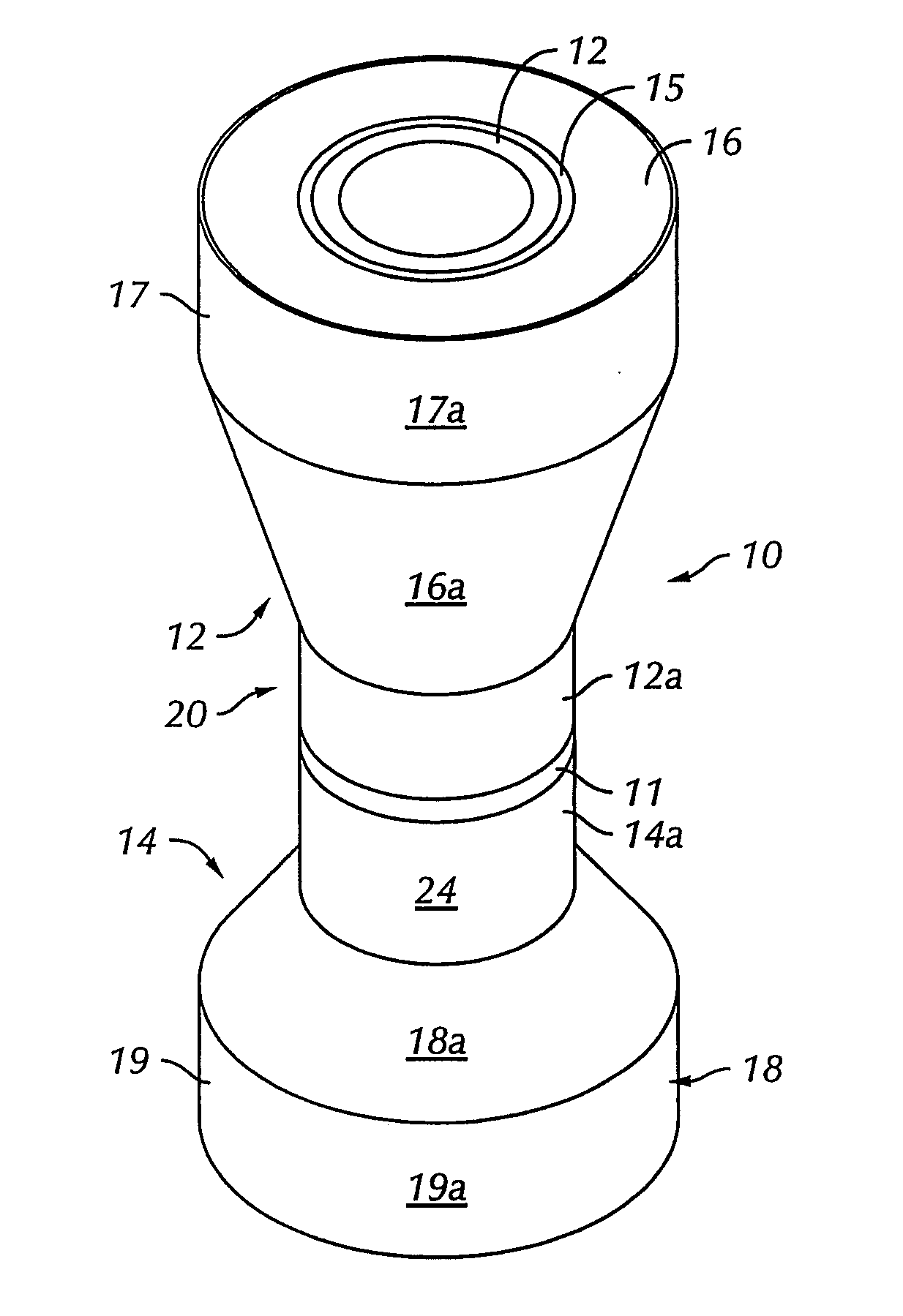

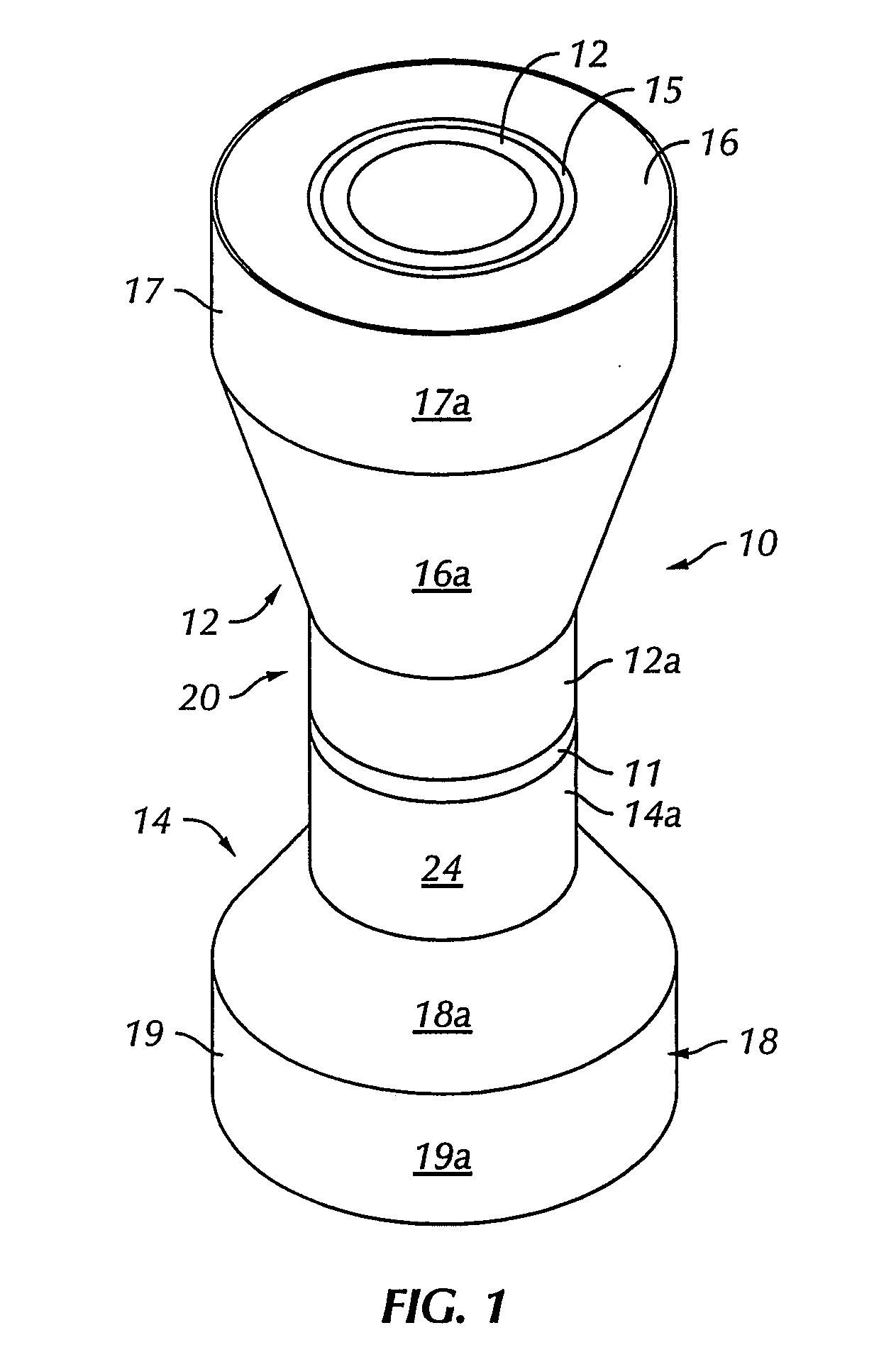

Pipeline field joint coating for wet insulation field joints

InactiveUS20080079260A1High strengthPrevent materialThermal insulationCorrosion preventionThermoplasticInfill

Thermoplastic wet insulation field joints for pipelines in bodies of water utilize the fast gelling nature of thermosetting systems, or other suitable fillers, coupled with a fully fused thermoplastic outer sheath for protecting the pipe joint from water contact. The outer sheath is fully fused circumferentially to the parent coating at each end of the field joint, and an outer closure patch is then fused to the sheath over the joining area and / or injection ports. This totally seals the filler material from direct contact with water, preventing water ingress from reaching the pipe surface. Hydrolysis of the infill material is thus also prevented. By use of a fast setting or solid infill material the system gains sufficient strength almost immediately to withstand the rigors of handling during the lay operation.

Owner:OFFSHORE JOINT SERVICES

Methanol diesel oil cleaning grade-raising emulsifier for vehicle

the invention discloses a cleaned standard-increasing emulsifier of vehicle carbinol gasoline, which is characterized by the following: loading positive octyl alcohol, positive heptyl alcohol, alcohol isopropylicum, positive butyl alcohol, positive decatyl alcohol, hexadecyl alcohol and spans 80 in the autoclave according certain weight percentage; stirring evenly under the condition of normal temperature without any fire.

Owner:段家祥

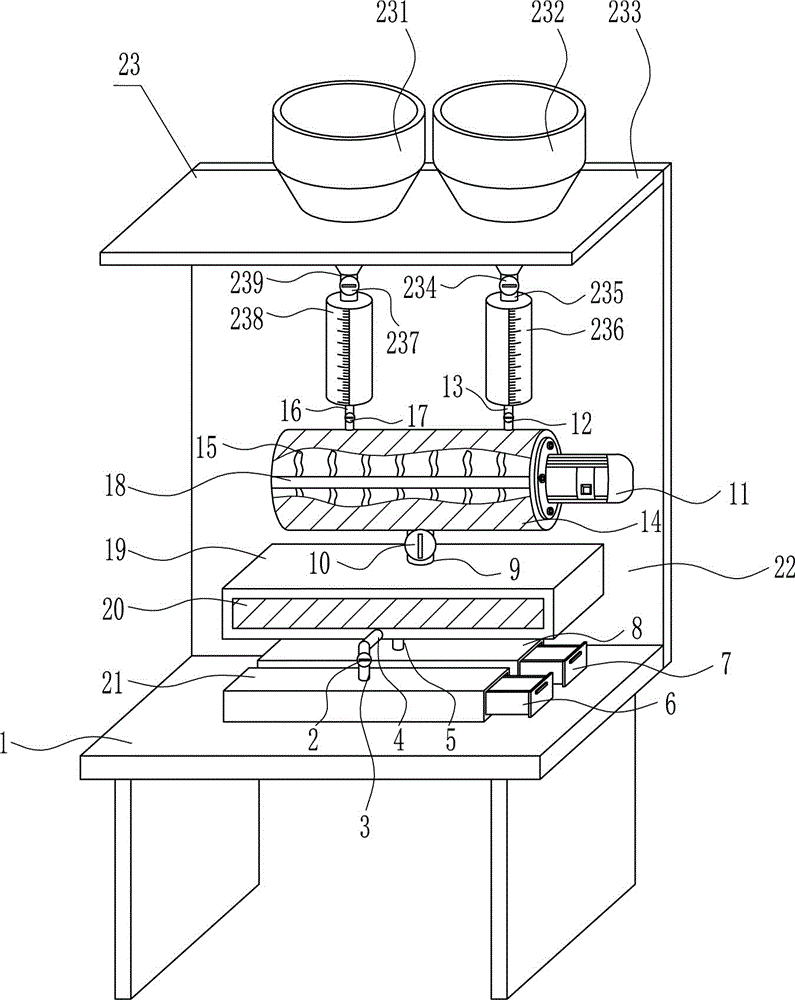

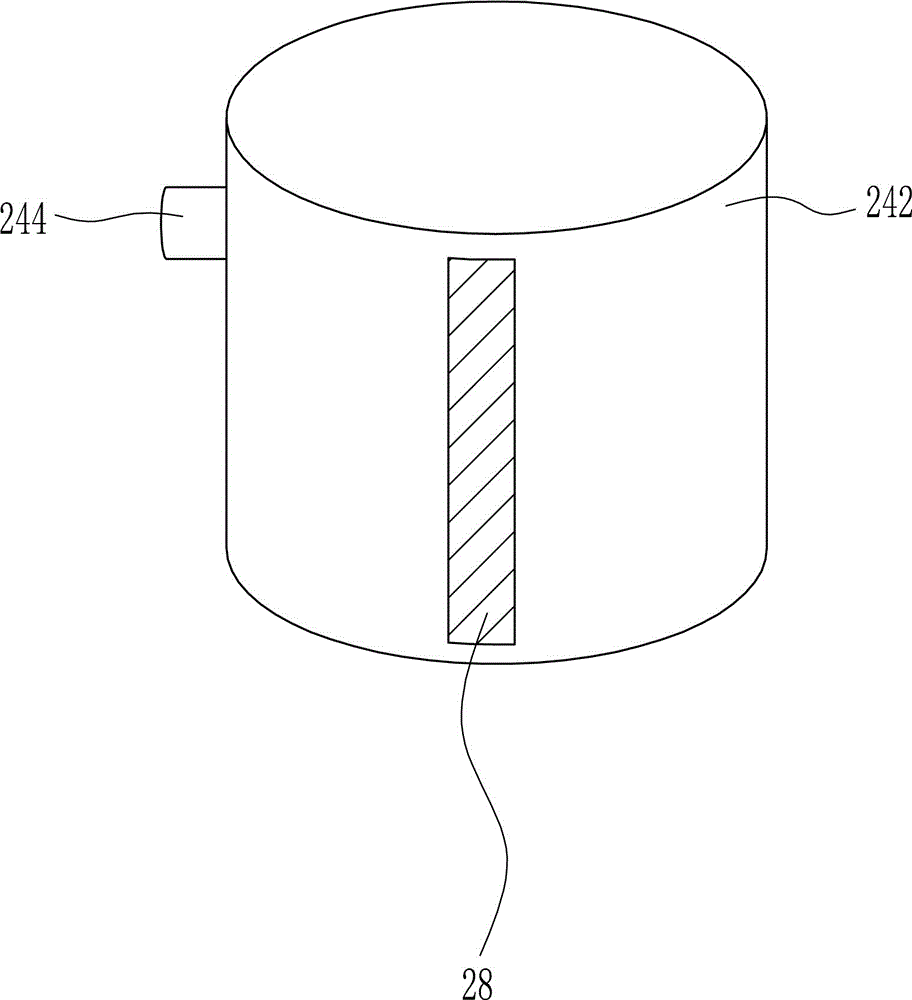

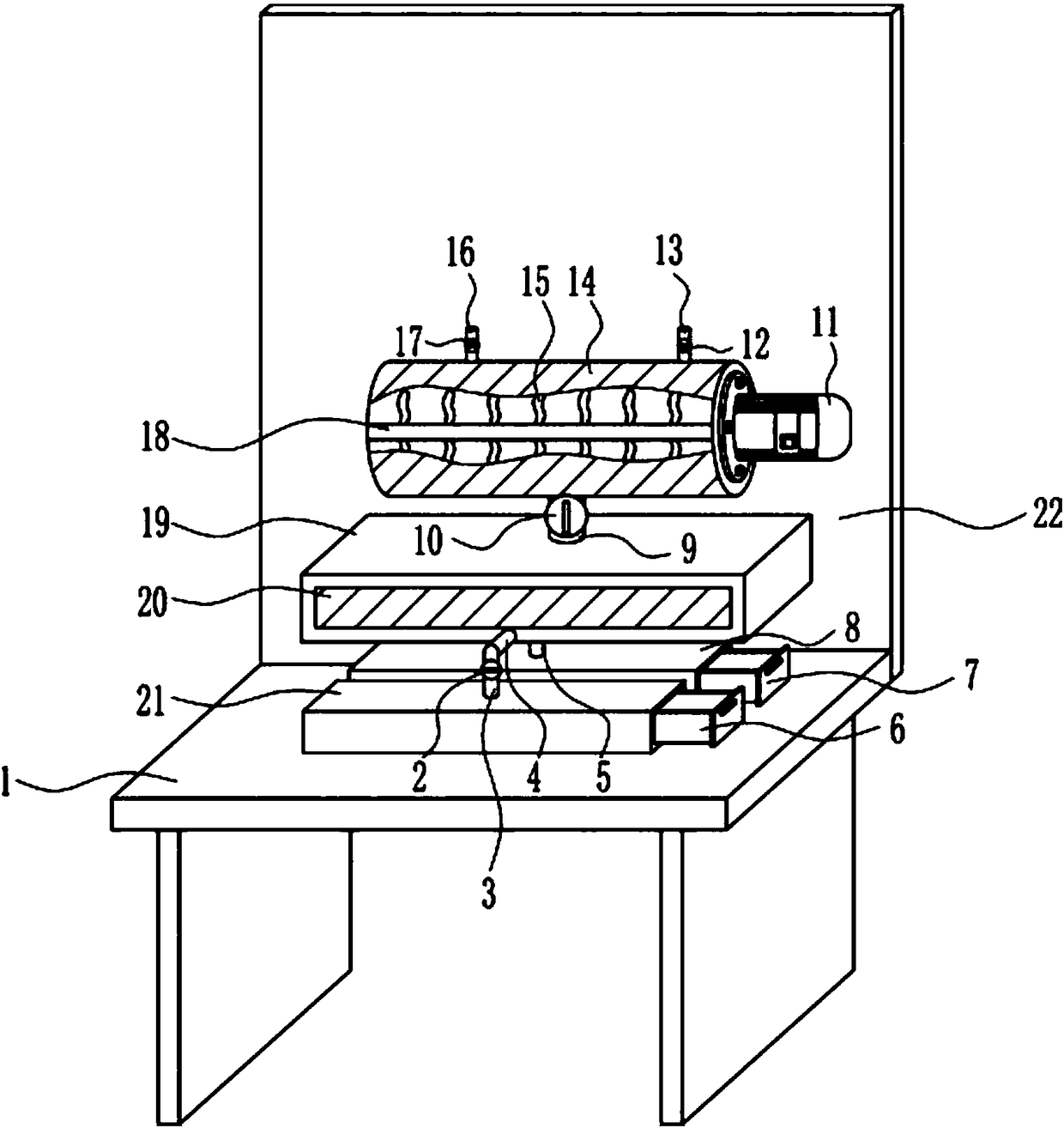

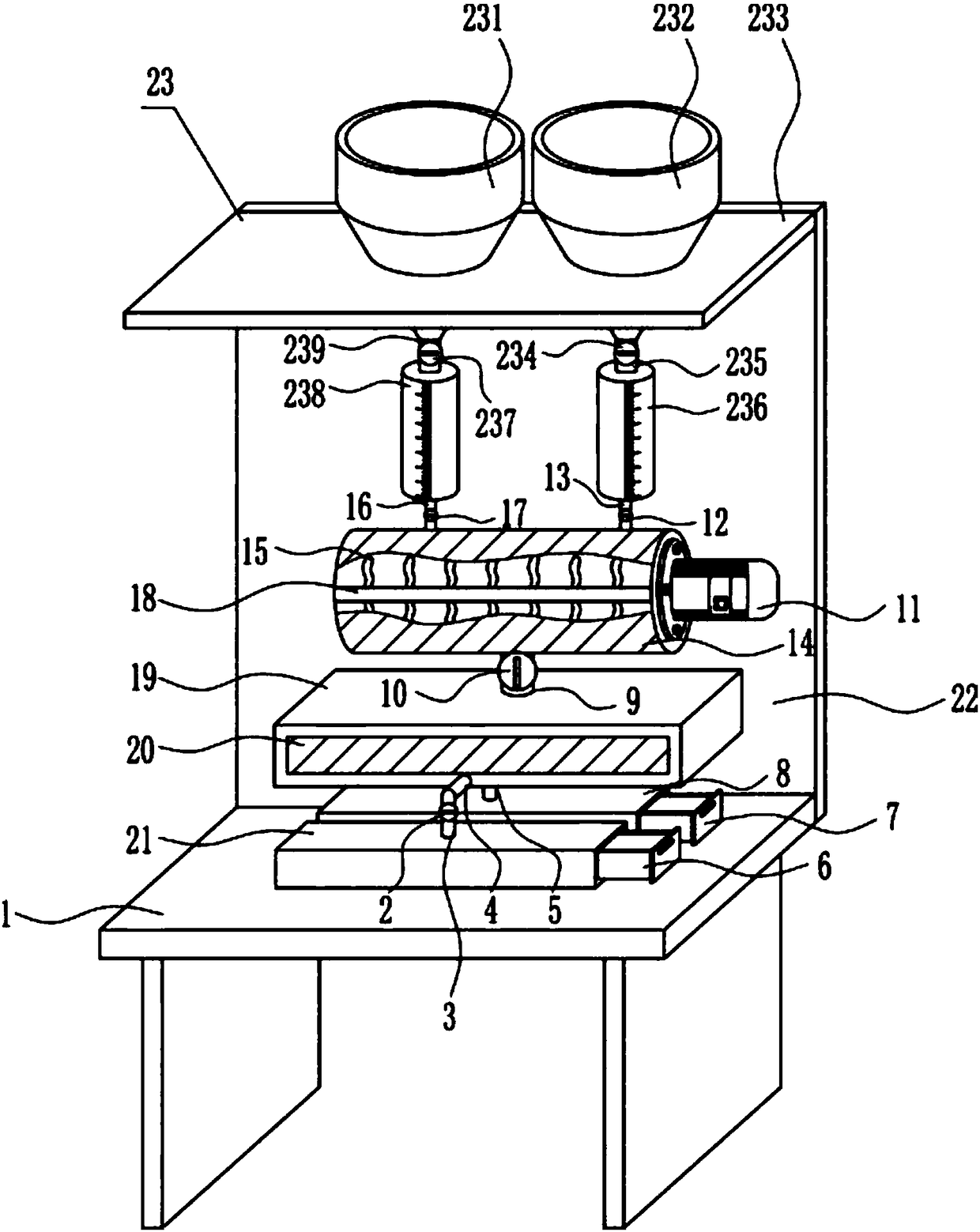

Rare earth oxide extraction equipment for rare earth waste recycling

InactiveCN106521149AFully fusedEasy extractionSolvent extractionProcess efficiency improvementScrapMother liquor

The invention relates to rare earth oxide extraction equipment, in particular to rare earth oxide extraction equipment for rare earth waste recycling. In order to achieve the technical aims, the rare earth oxide extraction equipment for rare earth waste recycling is good in extraction effect, high in extraction speed and capable of precisely observing the ratio of two solutions during mixing. To achieve the above technical aims, the rare earth oxide extraction equipment for rare earth waste recycling comprises a containing table, a first valve, a first liquid outlet pipe, a second liquid outlet pipe, a third liquid outlet pipe, a first storage box, a second storage box, a first storage tank, a fourth liquid outlet pipe and the like. A rear side plate is welded to the rear side face of the containing table. According to the rare earth oxide extraction equipment for rare earth waste recycling, the quantity of the mother solution and the quantity of the extraction solution can be precisely controlled through a first material metering pipe and a second material metering pipe.

Owner:充梦霞

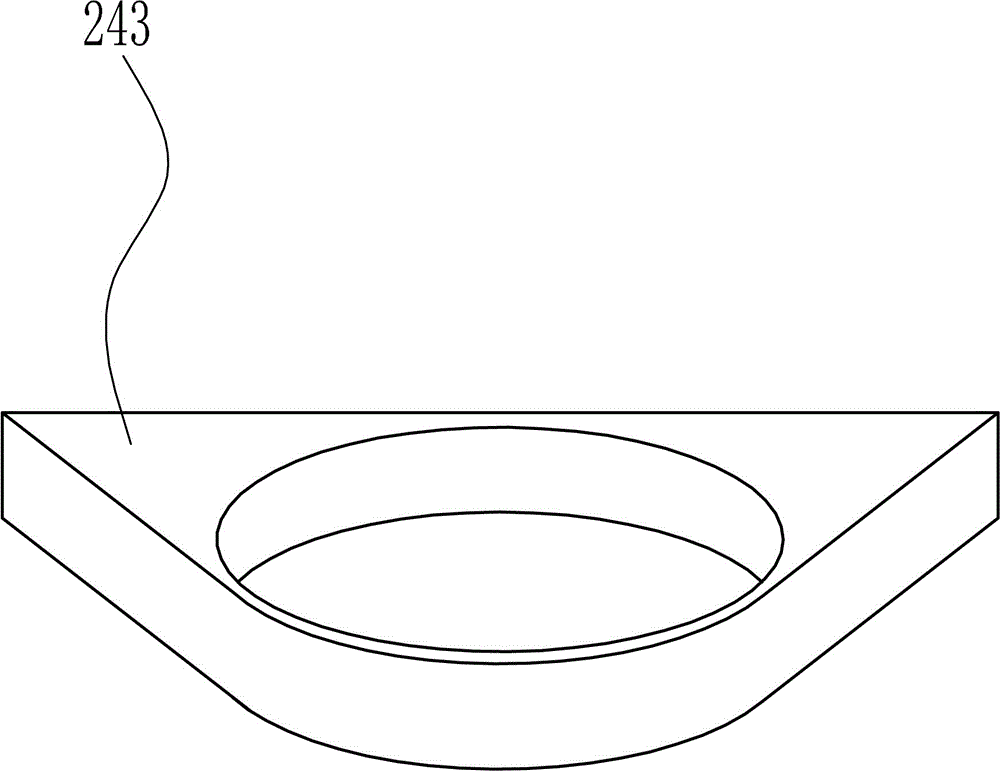

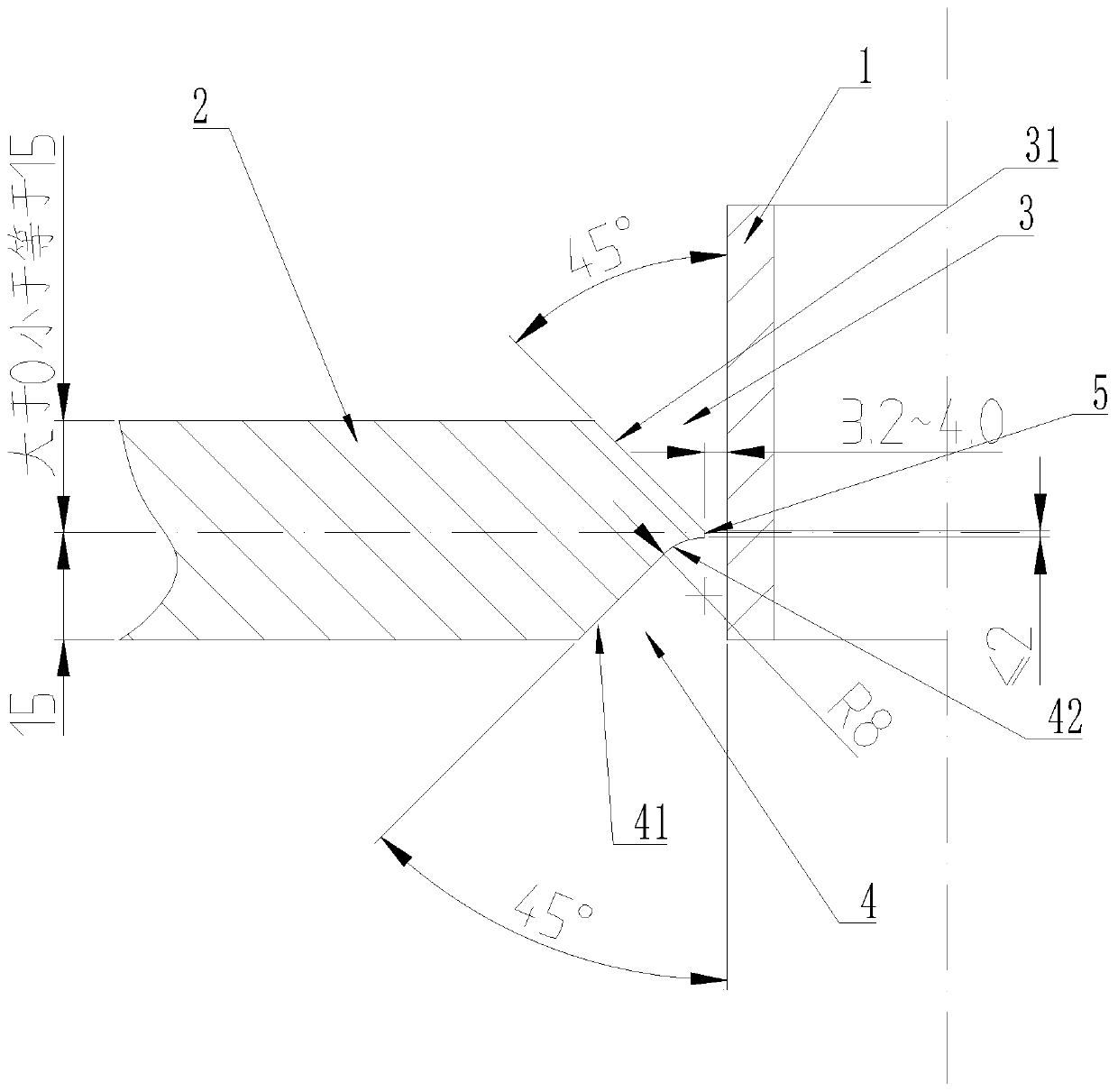

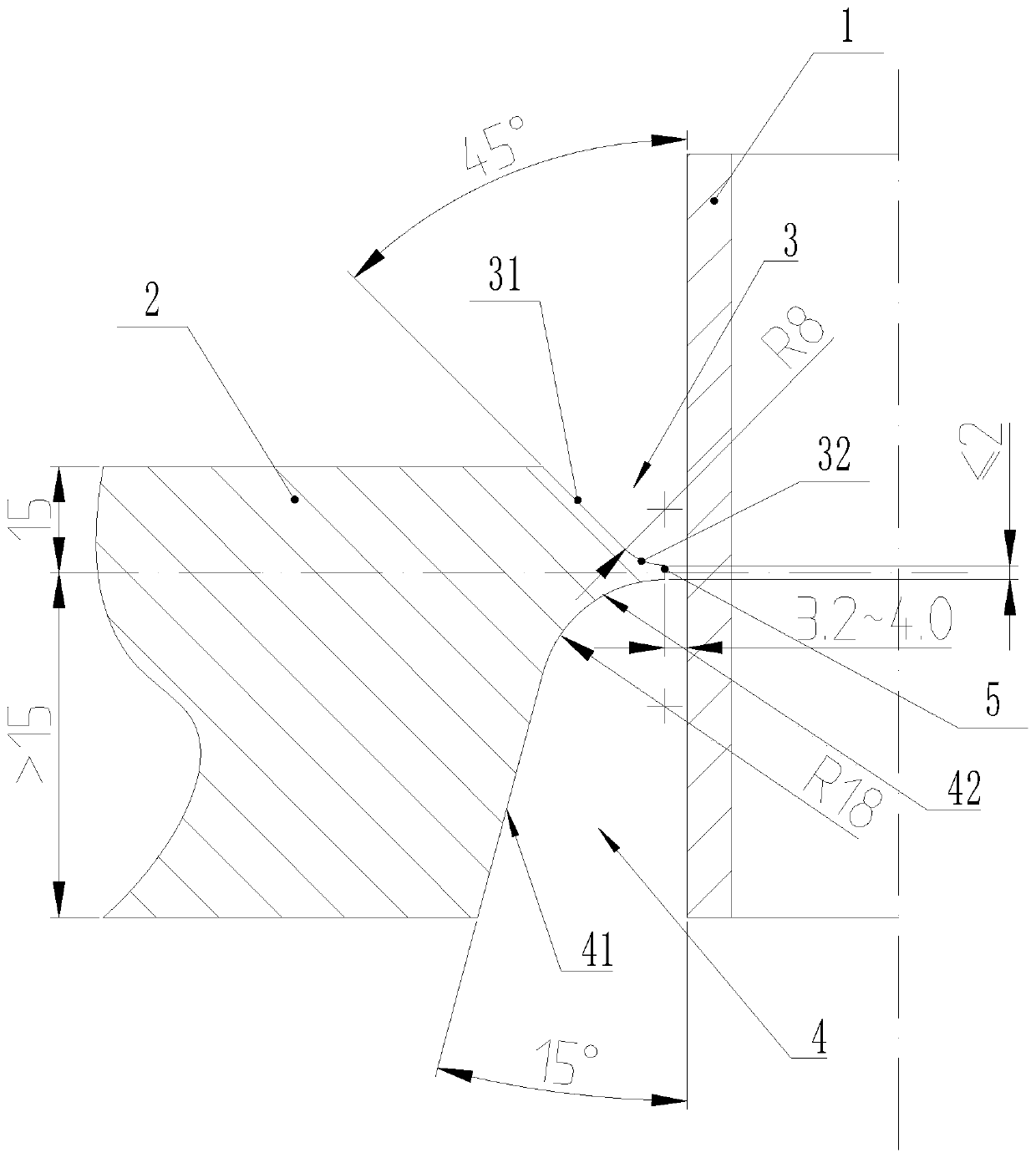

Welding groove form and welding process of container adapter tube or blind flange adapter tube

InactiveCN111438461AIncrease widthFully fusedArc welding apparatusWorkpiece edge portionsStructural engineeringWeld seam

The invention discloses a welding groove form and welding method of a container adapter tube or a blind flange adapter tube. According to the welding groove form, different groove forms are set according to the wall thickness, in this way, backing welding can be conveniently conducted through manual tungsten electrode argon arc welding, thus one-side welding both-side formation is completed, and the quality of a weld seam is more stable; and in the welding process, backing is conducted firstly through manual tungsten electrode argon arc welding, one-side welding both-side formation is achieved, the backing weld seam does not need to be polished, then whole welding is completed through manual arc welding, the weld seam is beautiful in formation, weld lines are uniform, the weld seam is stable in quality, and the deformation of a container or a blind flange is small.

Owner:江苏利柏特股份有限公司

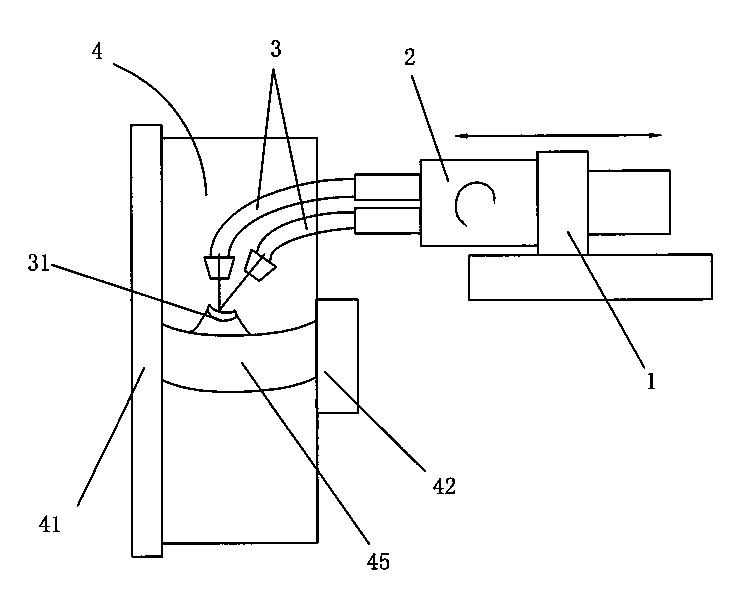

Method for steel rail surface treatment by laminar plasma

InactiveCN106637040AThe hardness enhancement effect is obviousImprove wear resistanceMolten spray coatingSurface finishingPlasma beam

The invention discloses a method for steel rail surface treatment by laminar plasma, and relates to the technical field of steel rail remanufacturing treatment. The method adopts a non-transfer arc laminar plasma generator as a heat source; the non-transfer arc laminar plasma generator moves relatively in parallel at constant speed along the longitudinal axis of a steel rail; a wire and powder feeding device axially feeds powder along the center of the non-transfer arc laminar plasma generator to spray composite powder to the surface of the steel rail; and a cladding layer is formed after injection cladding by the non-transfer arc laminar plasma generator. The method adopts laminar arc plasma beam remanufacturing system equipment to perform the heat surface reinforcement treatment for rail junctions, steel rails, wheels and other rail vehicle parts; and treated materials are more obvious in surface hardness reinforcing effect, and greatly improve the wear resistance.

Owner:四川金虹等离子技术有限公司

Device for generating carbonated water by immediately mixing water with carbon dioxide

InactiveCN107362706AIncrease contact areaExtension of timeTransportation and packagingMixersEngineeringTurbine

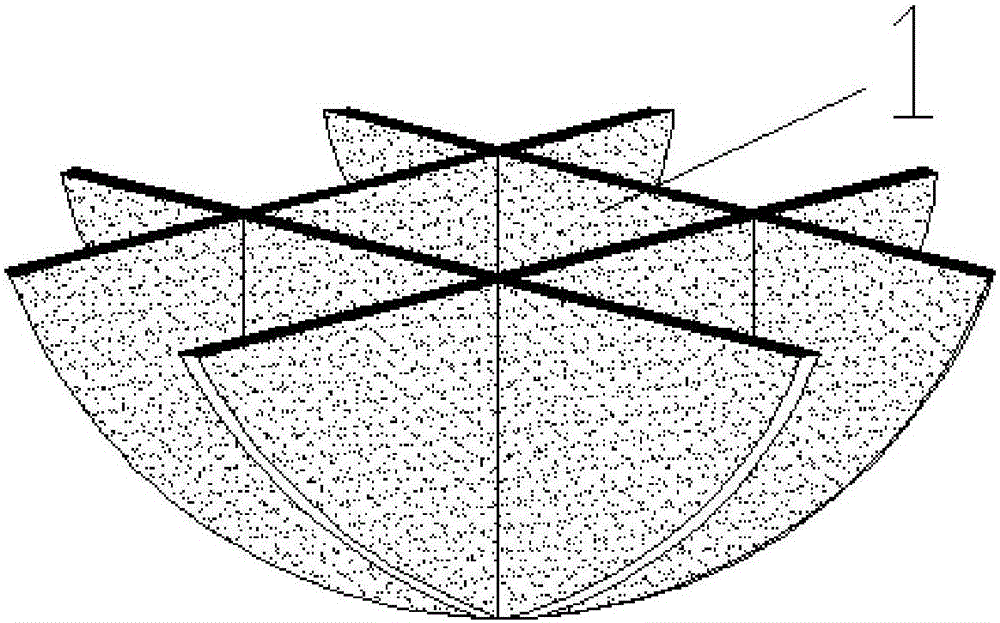

The invention discloses a device for generating carbonated water by immediately mixing water with carbon dioxide. The device comprises a cold water inlet, a carbon dioxide inlet, a water inlet pipe, a cold water one-way valve, a carbon dioxide one-way valve, an air inlet pipe, a three-way joint, a connecting pipe, a turbine pipe, a throttle hole, an X-shaped segmentation block, a static mixing pipe, a draining pipe, a throttle valve, a carbonated water outlet, a throttle valve adjusting knob, a lower turbine and an upper turbine, wherein a water inlet pipe and a water outlet pipe are respectively mounted at corresponding interfaces in two sides of the top of the three-way joint, a cold water inlet is formed in the top of the water inlet pipe, the cold water one-way valve is mounted on the water inlet pipe, and a carbon dioxide inlet is formed in the top of the air inlet pipe, the carbon dioxide one-way valve is mounted on the air inlet pipe; and a bottom outlet of the three-way joint is connected with the turbine pipe through the connecting pipe. According to the device, carbonated water which is good in taste and relatively sanitary can be provided; and furthermore, the device is convenient to use, small in volume and relatively safe and reliable.

Owner:CINO COFFEE MACHINE MFG CO LTD SHENZHEN

Aluminium alloy, core support prepared by same for forming of aluminum alloy casting and preparation of core support

InactiveCN102115838ASolve technical problems of poor fusionSolve the defect that non-dense gaps are easy to form cold shutFoundry mouldsFoundry cores5005 aluminium alloy5052 aluminium alloy

The invention relates to an aluminium alloy which comprises the following components by mass: 11-13% of Si, 0.15-0.30% of Mg, 86.7-88.85% of Al. Because the aluminium alloy provided by the invention has a melting temperature range lower than the pouring temperature of a casting aluminum alloy, the treated surface is easy to be melted by high-temperature casting aluminium alloy liquid and fused with a casting aluminum alloy matrix, and the technical problem of the poor fusion of a core support and an aluminium alloy casting body in the forming of a confined aluminum alloy casting in the prior art is effectively solved; and simultaneously, with the core support manufactured by the aluminium alloy, liquid flow stratifiedly flows as laminar flow when passing through the comb holes of the core support, and the flow process is subject to both the gravity action of the upper layer and the uplift action of the lower layer, which can effectively overcome the surface tension effect of liquid flow between layers and avoid the generation of stratified cold shut. The defect that existing core support always has incompact gaps which are easy to form cold shuts is effectively solved, and the internal quality requirements for confined castings are satisfied.

Owner:XIAN AERONAUSTIC POWER CONTROL ENG

Method for making opened red date health-care steamed bread

The invention discloses a method for making open-top red-date health-care steamed bread. The method comprises the following steps that: (1) according to weight portion, 100 portions of wheat flour are taken as a standard and added with corn flour, millet flour, baking powder and water, and the materials are stirred well to be pasty flour for first fermentation; (2) the pasty flour subjected to the first fermentation is added with wheat flour, small red bean flour and peanut flour, and the materials are stirred well to be mass-shaped flour for second fermentation; (3) the mass-shaped flour subjected to the second fermentation is added with milk and egg, kneaded well, added with dietary alkali and kneaded well into dough; (4) the dough in a step (3) is made into cylindrical dough; the periphery of the cylindrical dough is provided with dough holes; and red dates are inserted into the dough holes respectively; (5) a special impressing device is adopted to press the cylindrical dough from top to bottom so as to leave a mark and make the cylindrical dough into semi-finished steamed bread; and (6) the semi-finished steamed bread is steamed, and the steamed bread is in a round open-top shape. The method can ensure that staple food in diets of people is spongy in taste and suitable for various types of population for a long time, and has both health care function and auspicious appearance.

Owner:王淑敏

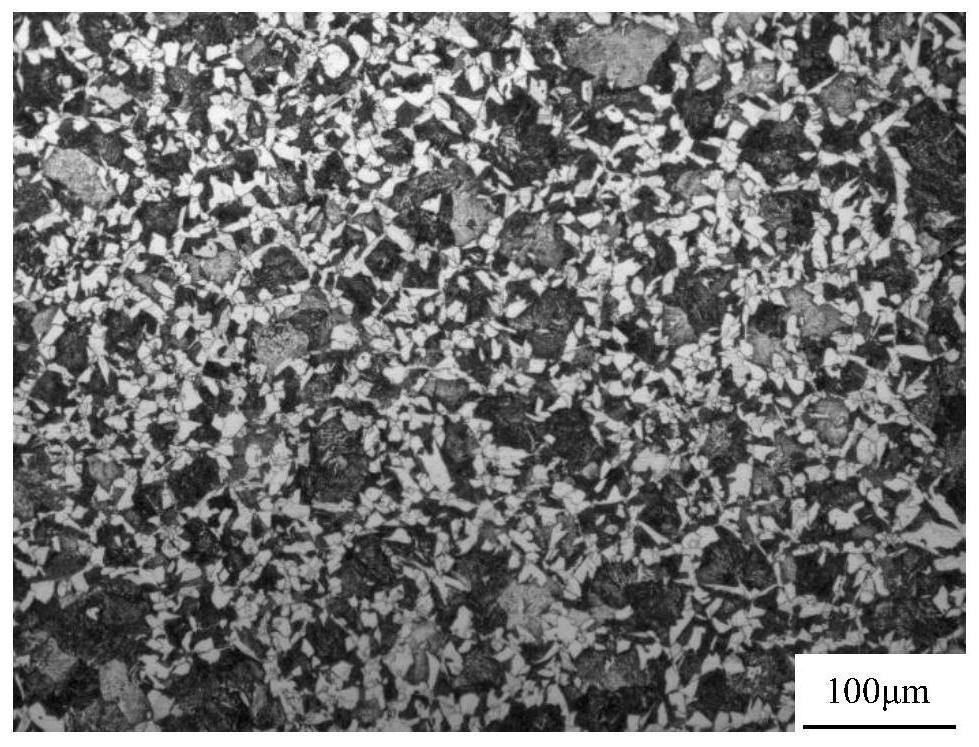

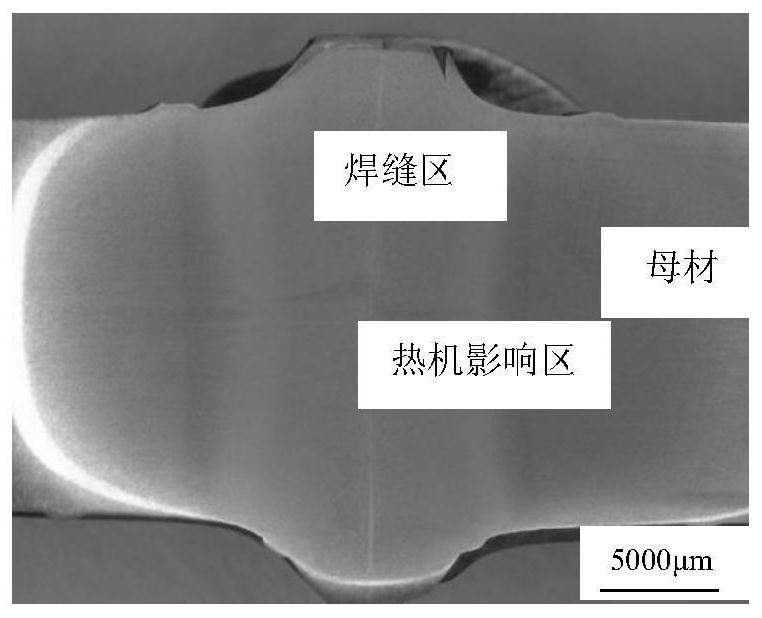

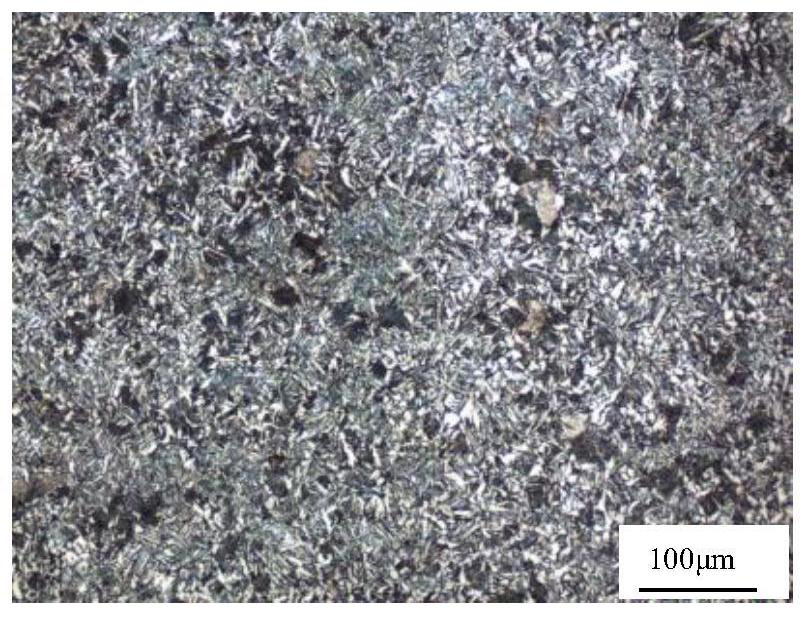

Flash welding method for HRB600 high-strength hot-rolled steel bar

ActiveCN111992862AImprove applicabilityEasy to operateResistance welding apparatusRebarFlash welding

The invention discloses a flash welding method for an HRB600 high-strength hot-rolled steel bar. The flash welding method comprises the following steps: (1) pretreating the welding end face of a steelbar to be welded; (2) clamping and fixing the steel bar to be welded, and adjusting the welding gap distance and the upsetting length; (3) setting flash welding process parameters matched with the specification of the steel bar to be welded; (4) starting a welding machine, and completing welding after the steel bar to be welded is sequentially subjected to welding area induction heating, flash discharging, pressure upsetting and pressure maintaining; and (5) carrying out air cooling to room temperature after welding. Flash welding of the high-carbon-equivalent HRB600 high-strength hot-rolledsteel bar can be achieved, a welding joint is made of acicular ferrite, polygonal ferrite and pearlite which are high in toughness, and the rapid, simple, convenient and reliable welding requirementsof the construction industry are met.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

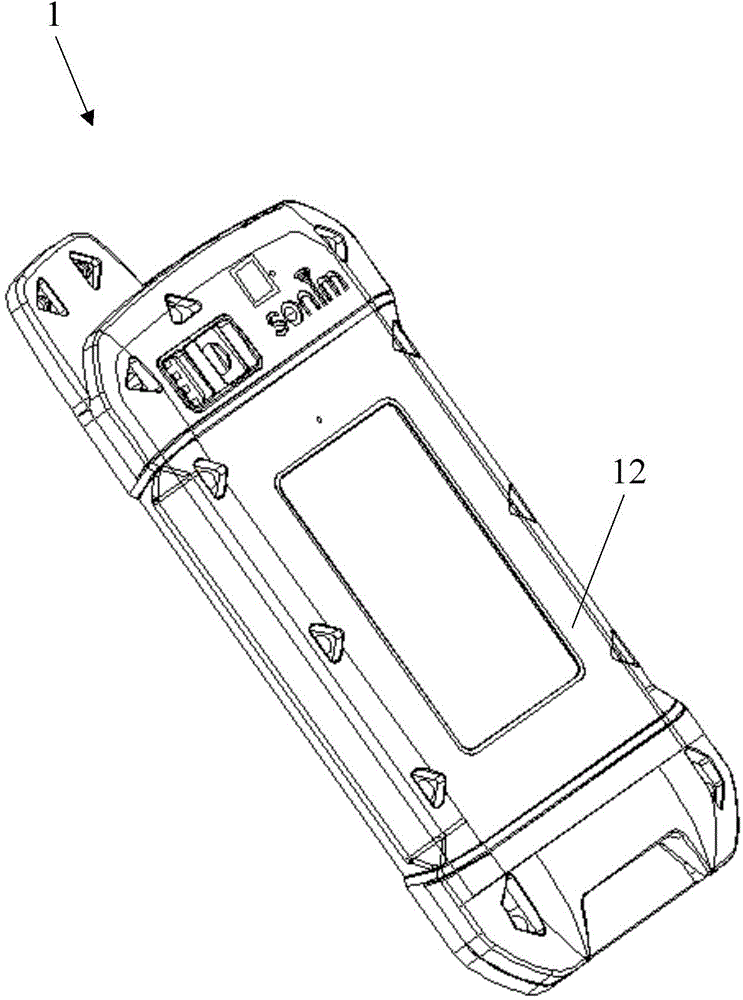

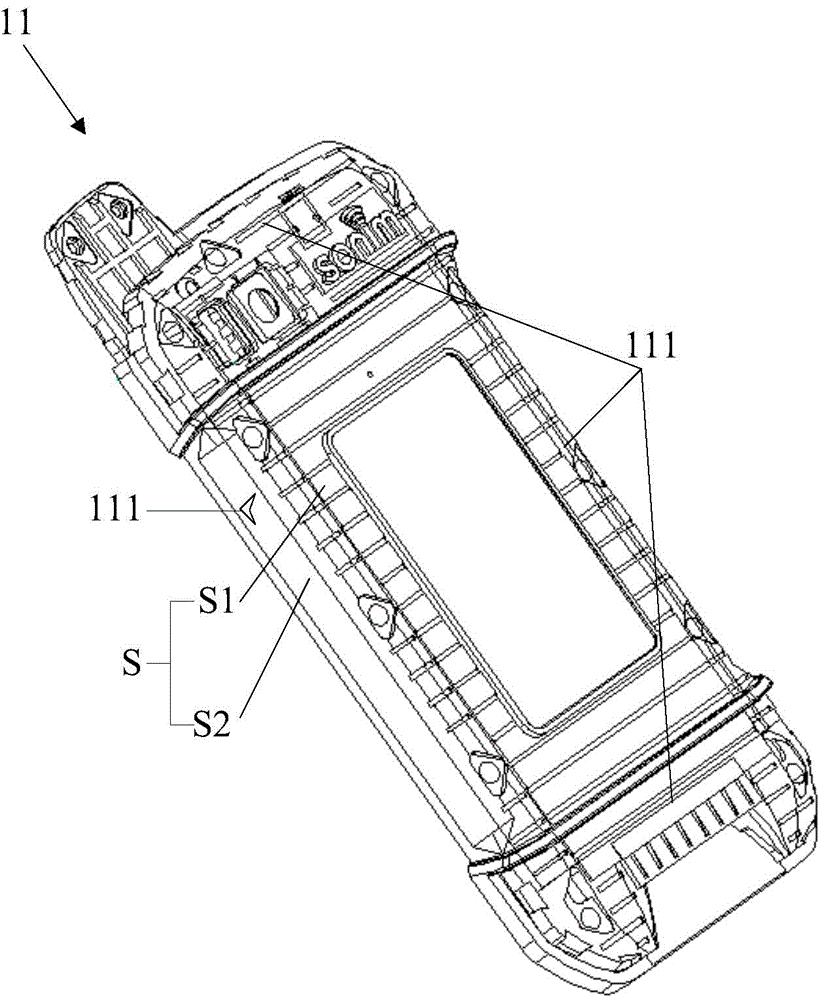

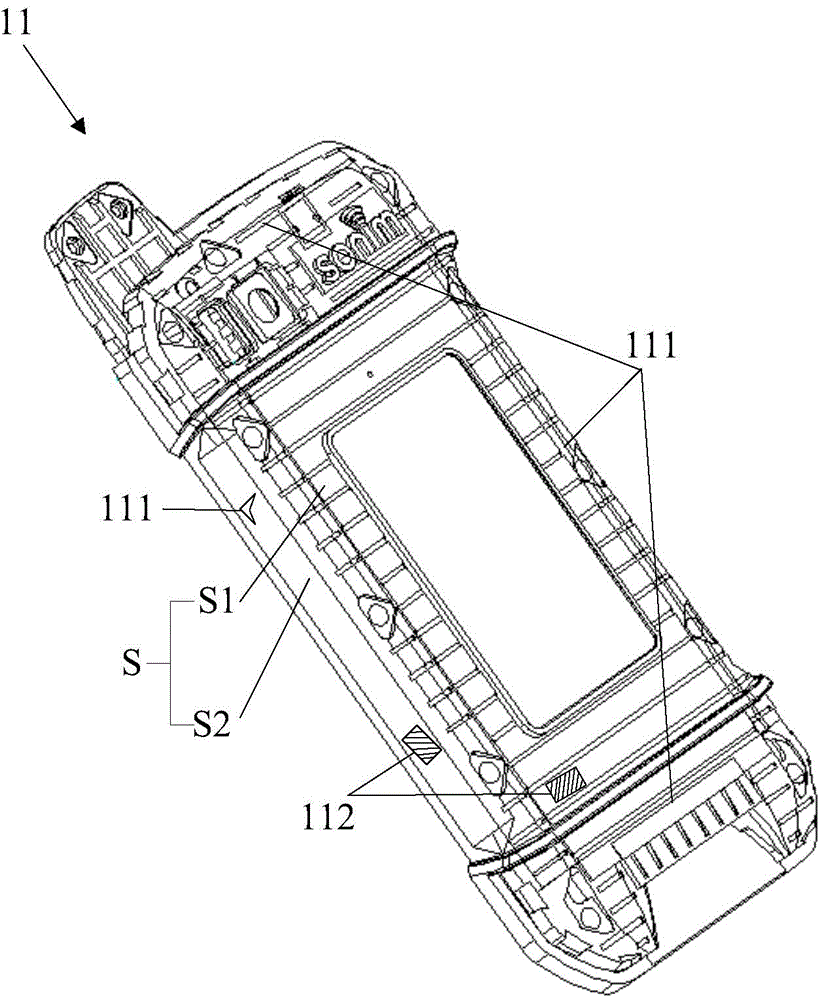

Double-shot injection moulding shell and injection mold

InactiveCN105984076AImprove bindingIncrease binding areaTelephone set constructionsEngineeringInjection moulding

The invention relates to structural design of a shell and discloses a double-shot injection moulding shell and an injection mold. The double-shot injection moulding shell comprises a first plastic layer and a second plastic layer combined with each other, wherein a first combining surface of the first plastic layer is provided with at least one first convex block; a second combining surface of the second plastic layer is provided with a first concave groove corresponding to the first convex block; the first plastic layer and the second plastic layer are combined through the first combining surface and the second combining surface; the first convex block is tightly embedded in the first concave groove. Therefore, the combining area of the two plastic layers of the double-shot injection moulding shell is increased to enable the combination of the two plastic layers to be firmer and prevent the two plastic layers from stripping.

Owner:SHANGHAI SIMCOM LTD

Metal surface gradient coating cladding method

InactiveCN106435442AAdapt to wideLower technical barriersMolten spray coatingSurface gradientPlasma generator

The invention discloses a metal surface gradient coating cladding method, and belongs to the technical field of metal surface heat treatment. The metal surface gradient coating cladding method comprises four steps of matrix surface pretreatment, coating material setting, coating cladding treatment and coating inspection; and in the coating cladding process, through specific setting of coating cladding equipment, a laminar flow plasma generator and a cladding spraying gun are adopted to provide a heat source to laminar flow plasma to perform gradient treatment for a metal surface. After at least two times of classing treatment, a coating layer with a gradient is formed, so that the cracking or stripping damage in an ultrahard coating layer is prevented, and the application range of the coating layer is wider; the laminar flow plasma is fast in heating speed, and the matrix temperature is convenient to control, and is not higher to prevent generation of annealing deformation; and meanwhile, as the laminar flow plasma continuously works to cause relatively slow cooling of a machine body, and a formed transition area is higher, the stress release is better for hard surface material cladding.

Owner:CHENGDU PLASMAJET SCI & TECH

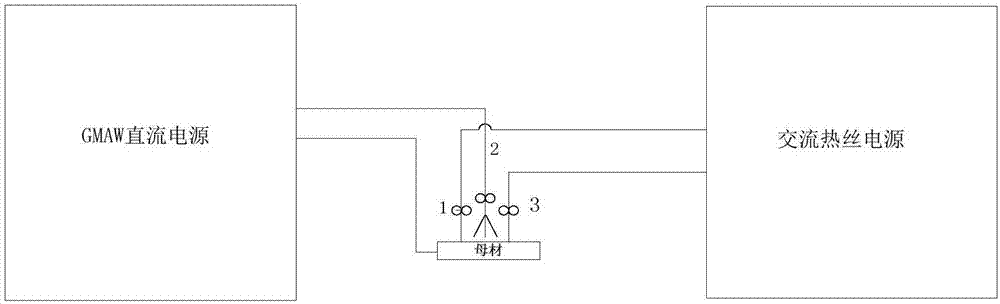

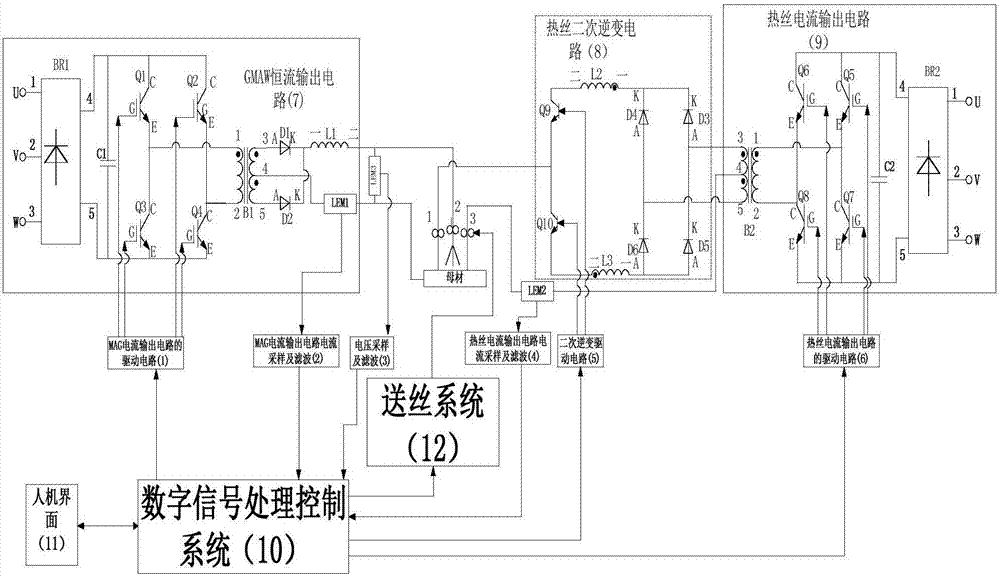

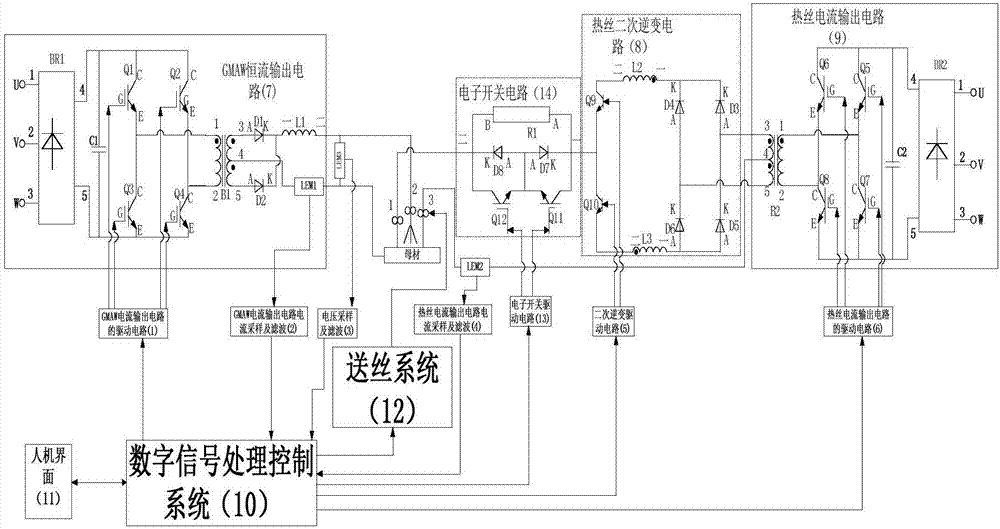

Hot wire welding device

ActiveCN107297561AHigh deposition rateDeposition speed is considerableElectrode supporting devicesWelding accessoriesHeat distributionParent material

The invention provides a hot wire welding device and belongs to the field of hot processing. A welding main arc is provided by a GMAW power supply, a parent material is connected with the negative electrode of the GMAW power supply, a welding gun is connected with the positive electrode of the GMAW power supply, and the parent material, the GMAW power supply and the welding gun form a current loop A; the current, voltage and dry elongation of the GMAW power supply can be freely adjusted according to experiment requirements, and the fusion depth and weld width of a weld pool can also be adjusted along with the current, the voltage and the dry elongation. Through alternate conduction of a power switch device in a hot wire current secondary inversion switching circuit, the power supply outputs low-frequency alternating current from a current output terminal, so that the current direction of a hot wire is switched back and forth, the hot wire effect on a welding wire is achieved through the switching, the welding efficiency is improved, and control over the swing of the main arc in the middle can also be achieved. A swing electric arc can also adjust the heat distribution of the electric arc, a heat affected zone can be adjusted, and the purpose that certain special alloy materials in the welding wire are not be damaged by electric arc overburning can be achieved. According to the device, energy input of the welding wire is reduced, and meanwhile, the swing electric arc plays an important role in improving the quality of the welding wire, so that the application range of the welding technology is improved.

Owner:BEIJING UNIV OF TECH

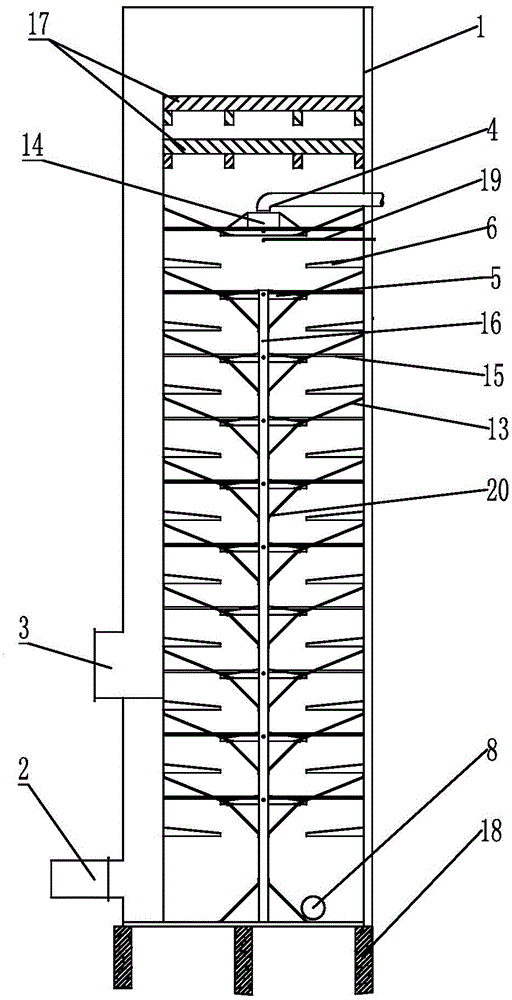

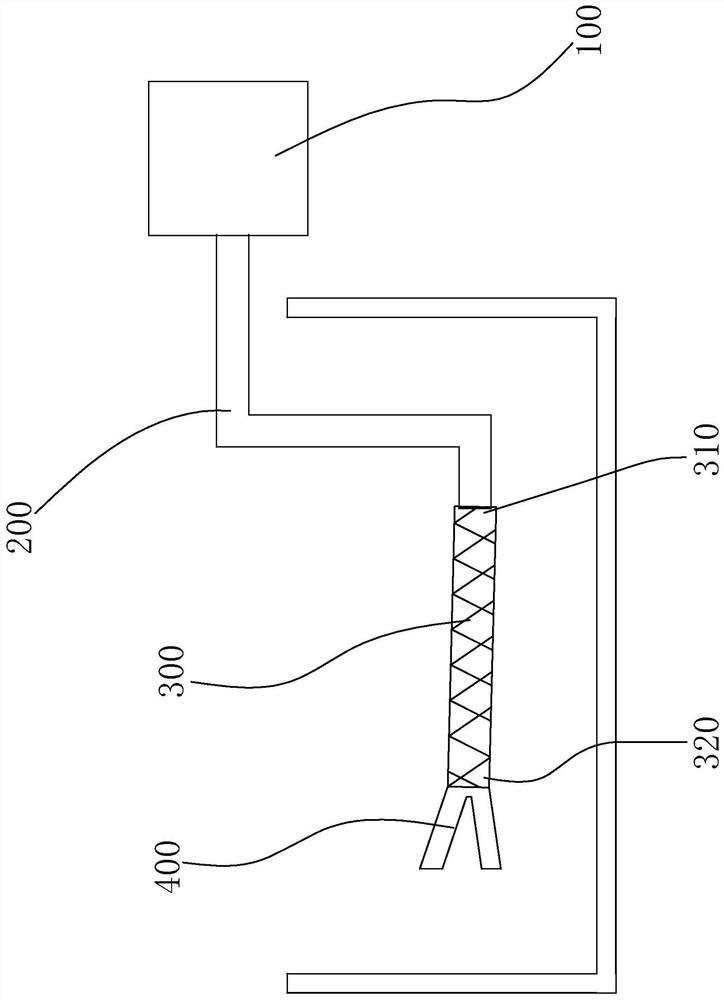

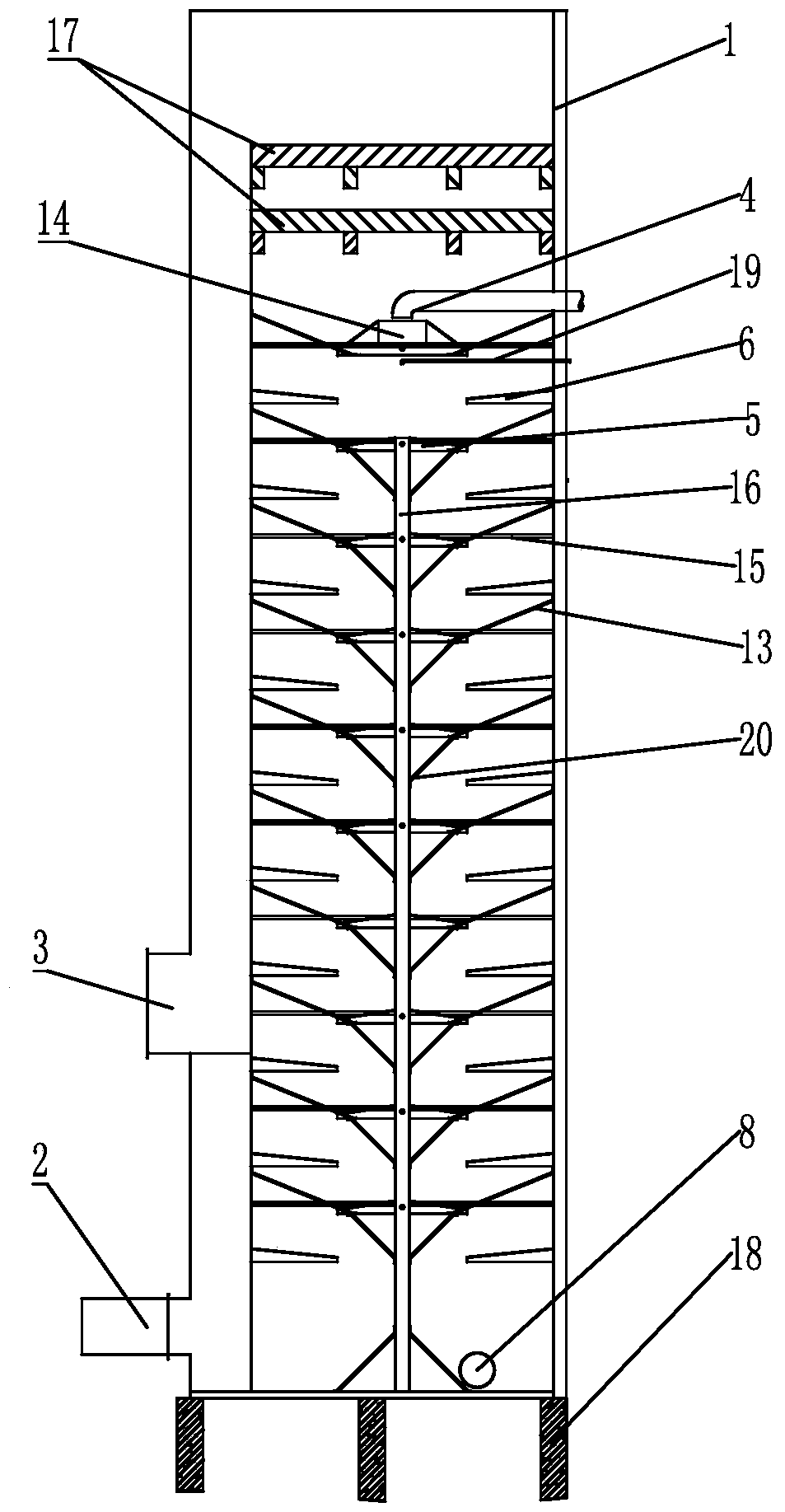

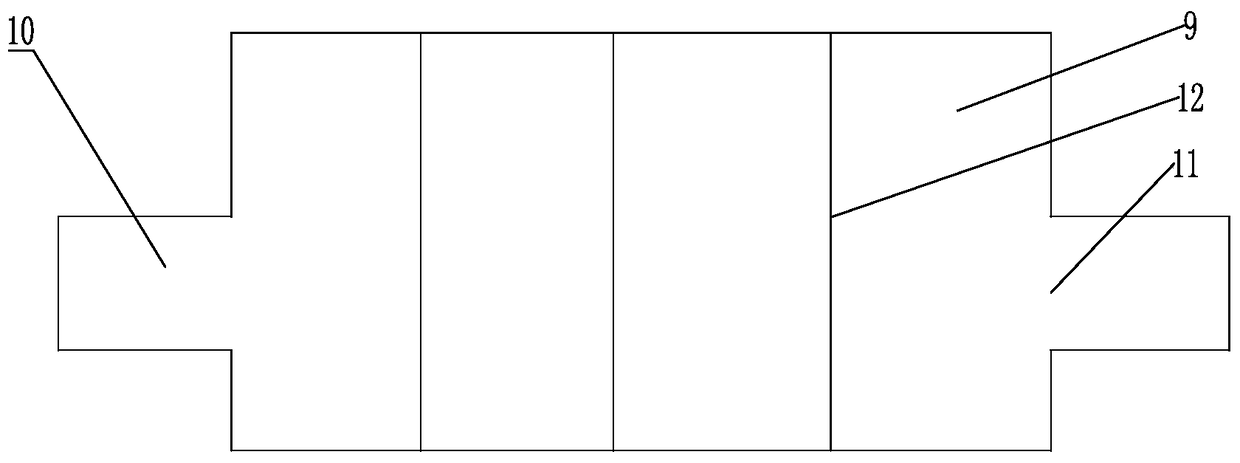

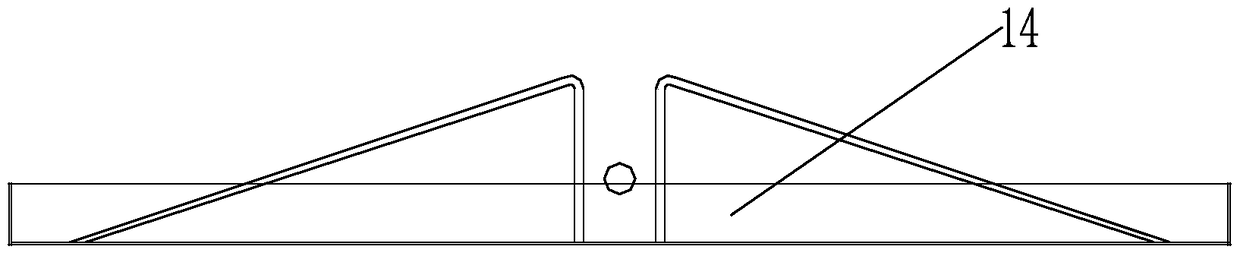

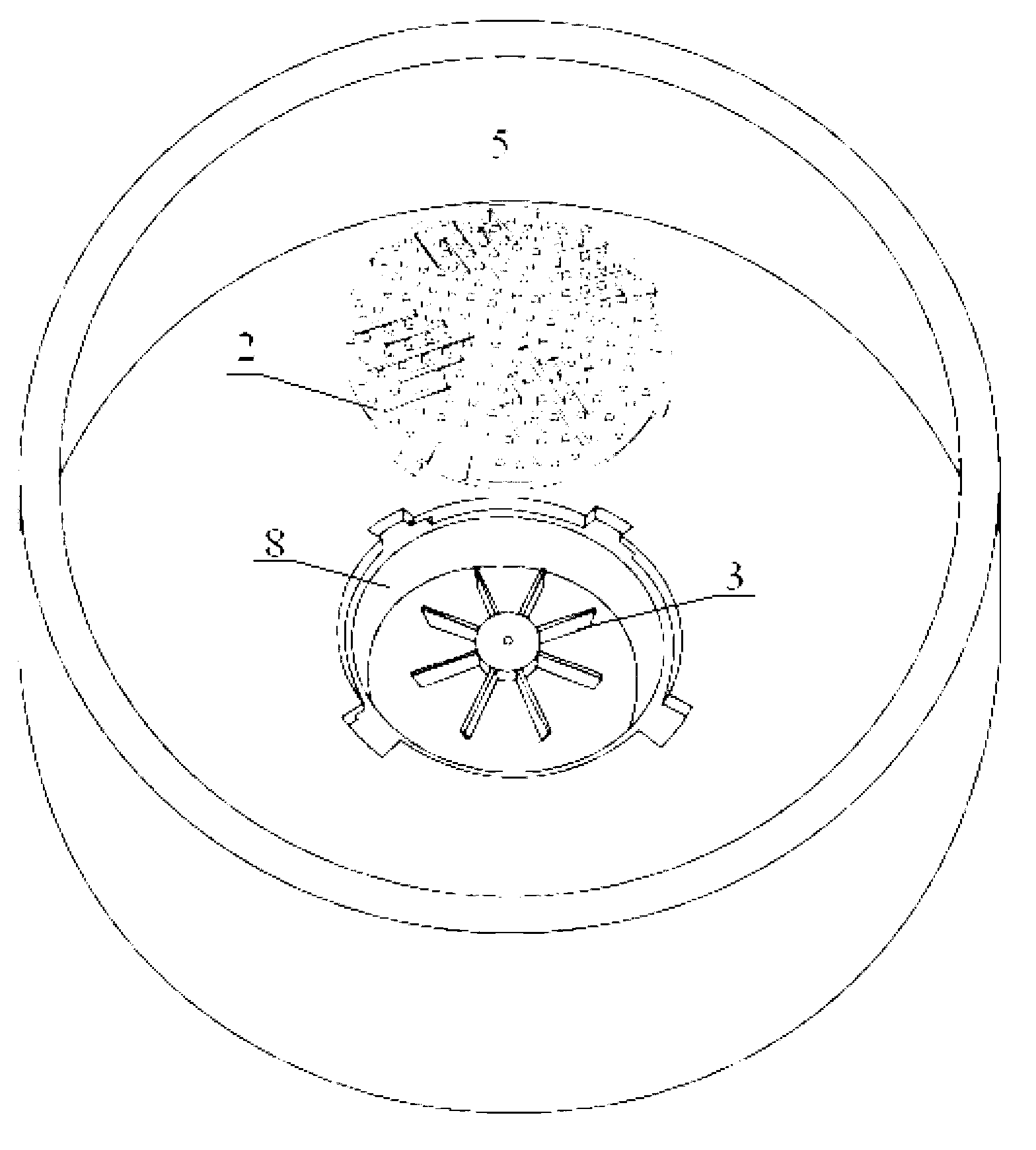

Closed multi-stage water curtain desulfurization system

ActiveCN104888594AImprove desulfurization effectFully fusedDispersed particle separationFlue gasEmission standard

The present invention discloses a closed multi-stage water curtain desulfurization system. The multi-stage closed water curtain desulfurization system comprises a boiler, a tower drum and a support, wherein the boiler is connected with the tower drum through a pipeline; a smoke inlet is formed in the lower part of the tower drum; a circulating water spray pipe is arranged at the upper part in the tower drum; a smoke discharging channel is formed in one side of the tower drum; a smoke outlet is formed in the smoke discharging channel; a demister is arranged at the upper part in the tower drum, and a water distribution disc is arranged below the demister; a stand column is arranged in the middle of the tower drum and provided with more than two stages of water curtain caps, and the water curtain caps are arranged at intervals from top to bottom; more than two layers of water collection discs are arranged at intervals on the two sides of the inner wall of the tower drum from top to bottom; a drain outlet is formed in the bottom of the tower drum and communicated with a sewage treatment tank. The facts that the flue gas of the boiler can reach the emission standard and the desulphurization efficiency is high are ensured, and meanwhile, the removal of desulphurized sewage and the circulating utilization of water resources are achieved, so that the water resources are saved.

Owner:梁山旭洋无烟尘节能环保设备有限公司

Preparation process of high-strength wood-plastic composite board

The invention belongs to the field of composite material preparation and discloses a preparation process of a high-strength wood-plastic composite board. The preparation process includes the steps of 1), preparing main materials; 2), breaking and crushing; 3), soaking, centrifuging and grinding; 4), calcining and grinding; 5), melting, shaping, cutting, sanding and performing surface pressing. The preparation process has the advantages that the process is simple, convenient and feasible and low in raw material cost, and the prepared wood-plastic composite board is high in mechanical strength, flame-retardant, damp-proof, environmentally friendly, free of pollution and the like.

Owner:杨昆

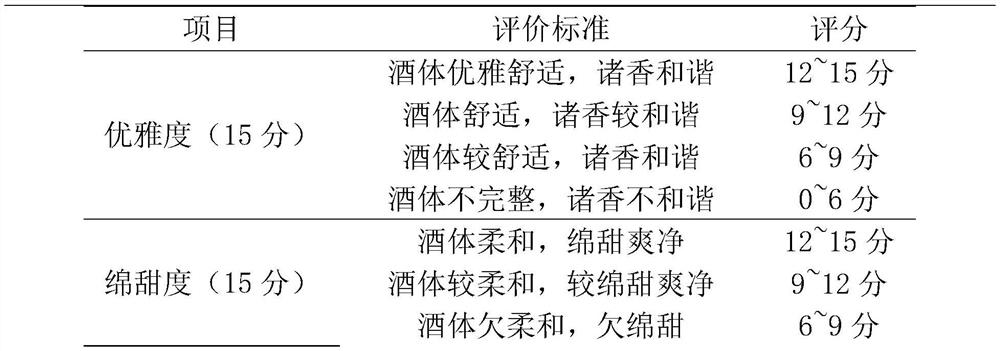

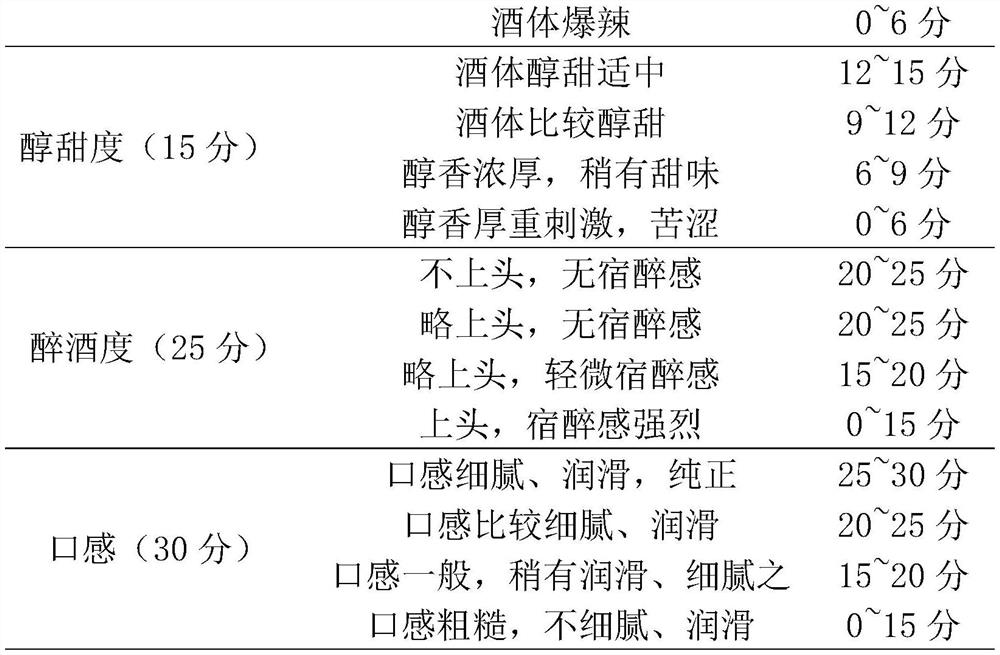

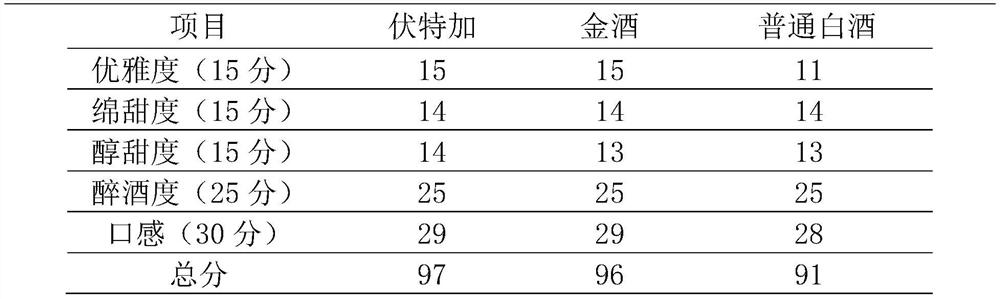

Cyclocarya paliurus foreign wine and preparation method thereof

PendingCN112063483AHomogeneous fusionImprove product qualityAlcoholic beverage preparationBiotechnologyCyclocarya

The invention provides a cyclocarya paliurus foreign wine. The cyclocarya paliurus foreign wine is prepared by taking cyclocarya paliurus as a raw material, adding 7-1000 times (v / w, ml / g) of foreignwine for soaking, and conducting storing for 5 hours to 200 days. The cyclocarya paliurus wine of the present invention has the characteristics of elegant and soft wine body, rich taste gradation, soft taste, harmonious fragrance, sweetness, astringency, sourness, sweetness after taste and body fluid regeneration and the like, and provides a wine body with better experience for consumers.

Owner:SICHUAN WANGE AGRI TECH CO LTD

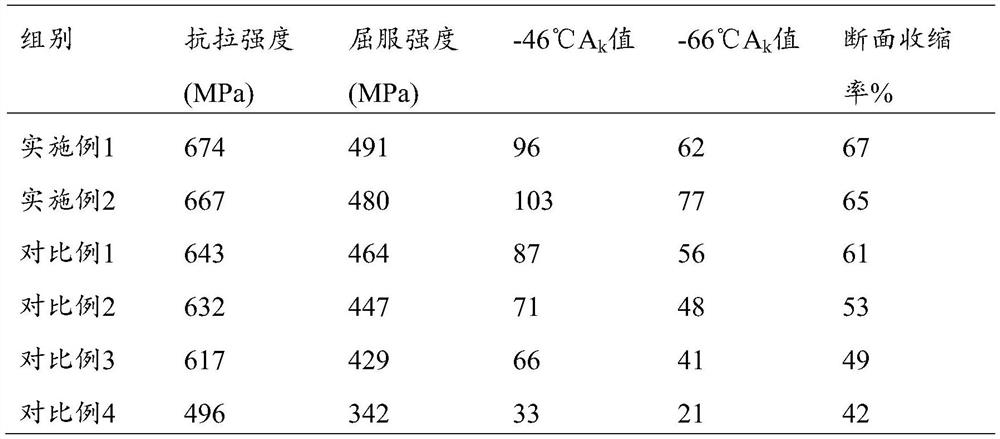

Low-temperature carbon steel valve casting material and manufacturing method thereof

ActiveCN111850380AImprove mechanical propertiesFully fusedFurnace typesHeat treatment furnacesNiobiumManganese

The invention discloses a low-temperature carbon steel valve casting material and a preparation method thereof as well as a method of using the material to prepare a low-temperature valve casting. A composite carbon steel material is prepared from ferrite low-temperature steel base materials and alloy additive materials; and the alloy additive materials comprise at least one of sub-alloy materialsincluding a niobium-manganese-iron alloy and a rare earth-iron alloy. Furthermore, in combination of a specific hot treatment method, the problem that the valve casting is relatively low in low-temperature impact toughness value under a medium to low temperature, particularly an extremely low temperature is solved.

Owner:南平市建阳区湛卢精密制造有限公司

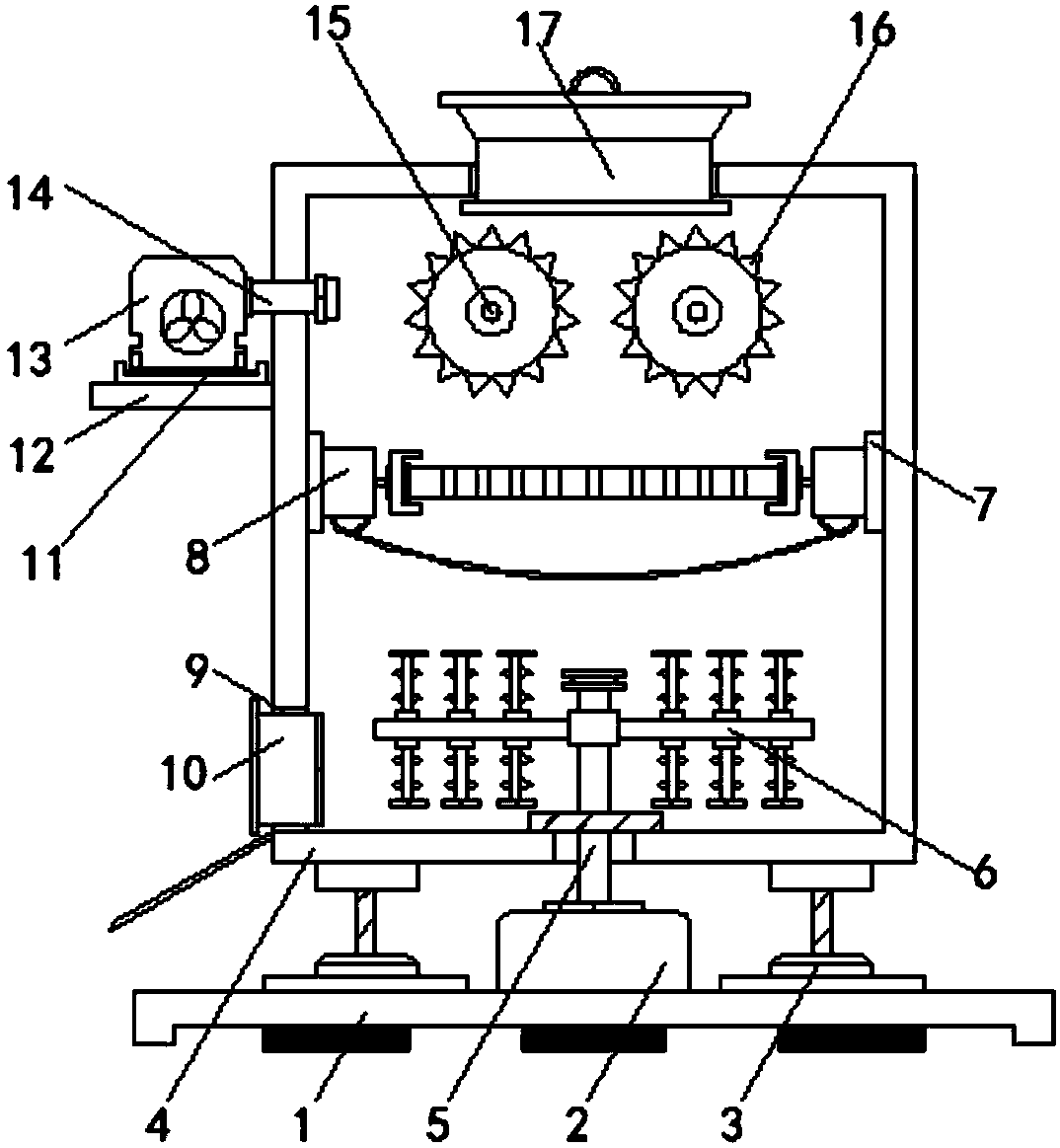

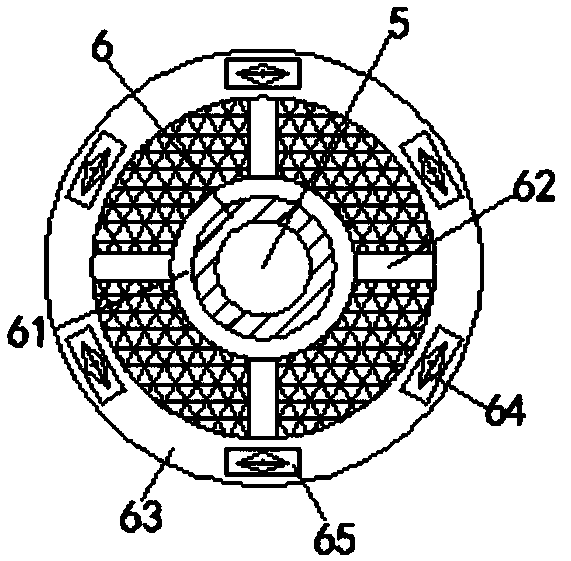

Asphalt mixing device for road pavement

The invention relates to the technical field of road pavement, and discloses an asphalt mixing device for the road pavement. The asphalt mixing device comprises a base, wherein a motor is fixedly arranged at the top part of the base; supports located at two sides of the motor are fixedly arranged at the top part of the base; a processing box is fixedly arranged at the top parts of the supports; anoutput shaft of the motor is fixedly provided with a rotating shaft of which one end penetrates through and stretches into a cavity of the processing box through a coupler; a stirring mechanism located in the cavity of the processing box is sleeved arranged at the outer side of the rotating shaft; fixed blocks are fixedly arranged on two inner side walls of the cavity of the processing box; screening mechanisms are fixedly arranged at opposite sides of the two fixed blocks; a discharging hole is formed in the left side wall of the processing box; a sealing plug penetrating through the discharging hole is arranged at the left side of the processing box; a supporting plate is fixedly arranged at the left side of the processing box; a supporting base is fixedly arranged at the top part of the supporting plate. The asphalt mixing device for the road pavement, disclosed by the invention, is good in mixing processing effect and convenient for later processing and use.

Owner:山东远通公路工程集团有限公司

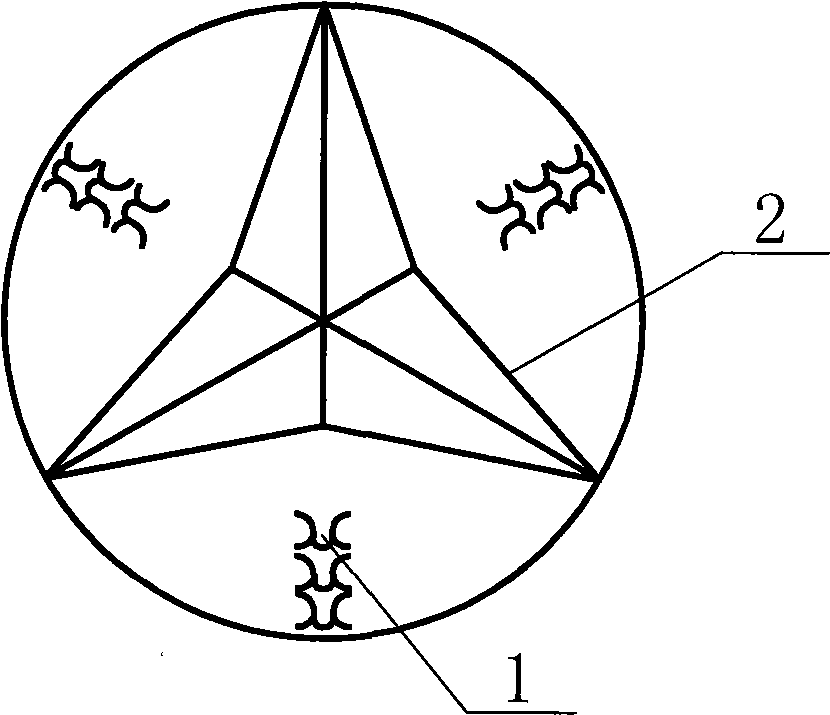

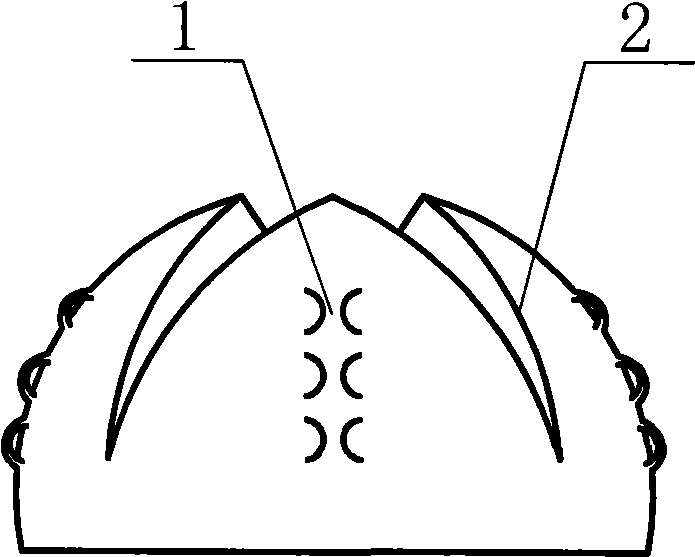

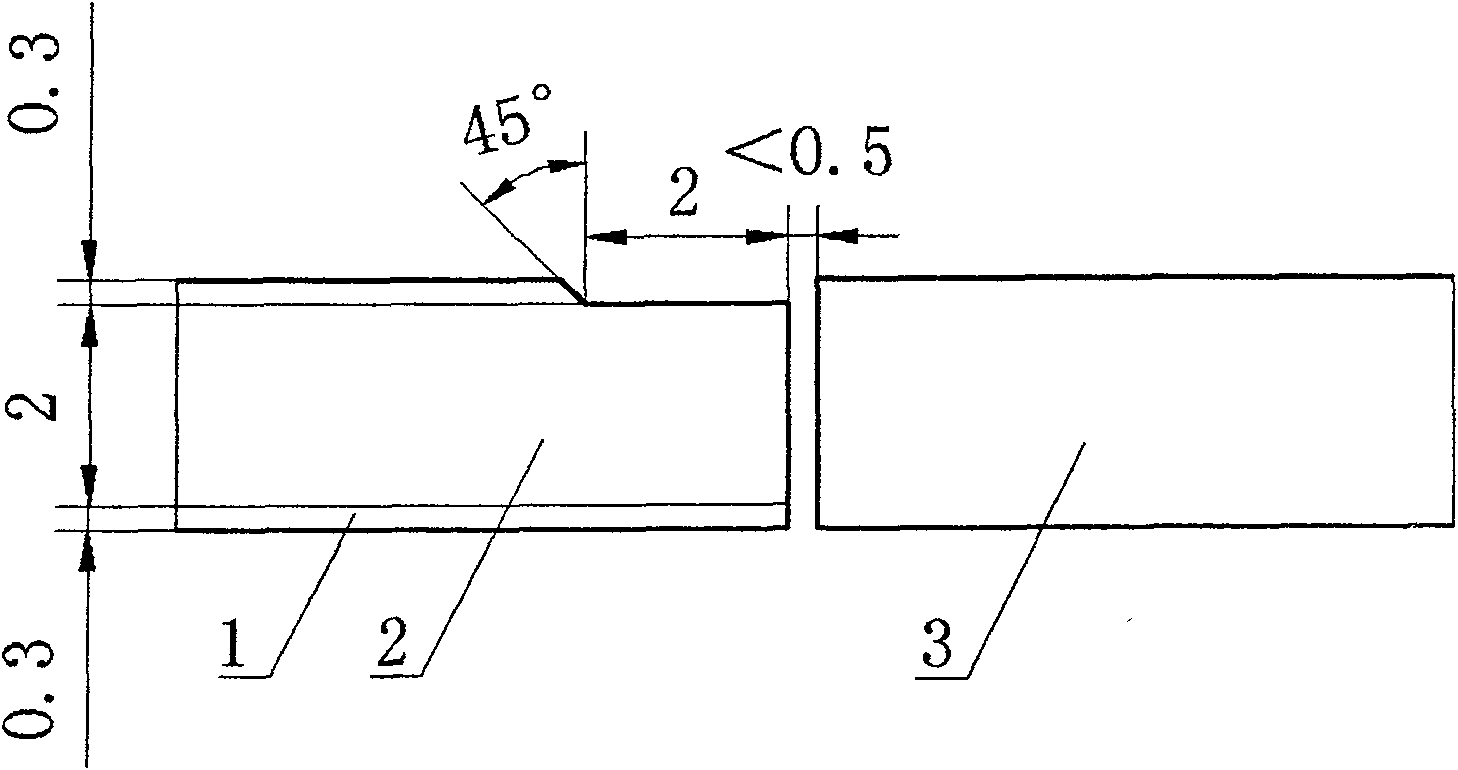

Filler wire argon tungsten arc process of super nickel/NiCr stacking compound material

InactiveCN100581704CGood miscibilityHigh bonding strengthArc welding apparatusWelding/soldering/cutting articlesCrazingAlloy

The invention discloses a filler rod argon tungsten arc process for a Super-Ni / NiCr laminated composite material and a dissimilar stainless steel material. The process comprises the steps of removing a Super-Ni multilayer on the joint to be welded on the Super-Ni / NiCr laminated composite material to expose a base layer before welding as shown by the attached figure; polishing the base layer and the stainless steel joint with sand paper until metallic luster appears; taking Cr25-Ni13 alloy system welding wire as a filler metal, and adopting manual rod-filling argon tungsten-arc welding to weld in a horizontal position. The technological parameters of the argon tungsten-arc welding are as follows: the welding voltage is 10-13V, the welding current is 80-110A, the argon flow rate is 8-15L / min, and argon arc short arc is kept down to weld. The method is applicable to welding the Super-Ni / NiCr laminated composite material under the conditions of heat, corrosion and high temperature resistance, particularly to welding the laminated composite material with the dissimilar stainless steel material. The welding joint obtained has the advantages of aesthetic welding seam, no crack or air hole, good interface fusion, and joint strength close to parent metal, with the elongation ratio being more than 30%.

Owner:SHANDONG UNIV

A kind of ultra-thick material layer sintering production method

ActiveCN106350666BIncreasing the thicknessReduce fuel consumptionFluidised-bed furnacesSolid fuelLayer thickness

The invention discloses a super-thick bed layer sintering production method. The super-thick bed layer sintering production method is characterized in that during sintering production, material distribution is performed twice, ignition is performed twice, and carbon-containing pellets are added after first material distribution and before first ignition as well as after second material distribution and before second ignition; the thickness of the mixture distributed for the first time is 600-800 mm, the carbon-containing pellets are added into the mixture distributed onto a sintering machine for the first time, the quantity of the carbon-containing pellets added around the mixture is 1-2 times of that of the carbon-containing pellets added into the middle of the mixture, and ignition and down draft sintering are performed; second material distribution is performed after the sintering lasts for 10-25 minutes, the material distribution thickness is 400-600 mm, the carbon-containing pellets are added into the sintering mixture distributed for the second time, the quantity of the carbon-containing pellets added around the mixture is 1-2.5 times of that of the carbon-containing pellets added into the middle of the mixture, and the second ignition and down draft sintering are performed. The super-thick bed layer sintering production method has the advantages that the upper mixture and the lower mixture are sintered at the same time, and the bed layer thickness can be increased to 1.3-1.4 m; the heat supply and mineralization time of the upper and peripheral bed layers are optimized, sinter quality can be improved, and solid fuel consumption is lowered.

Owner:ANGANG STEEL CO LTD

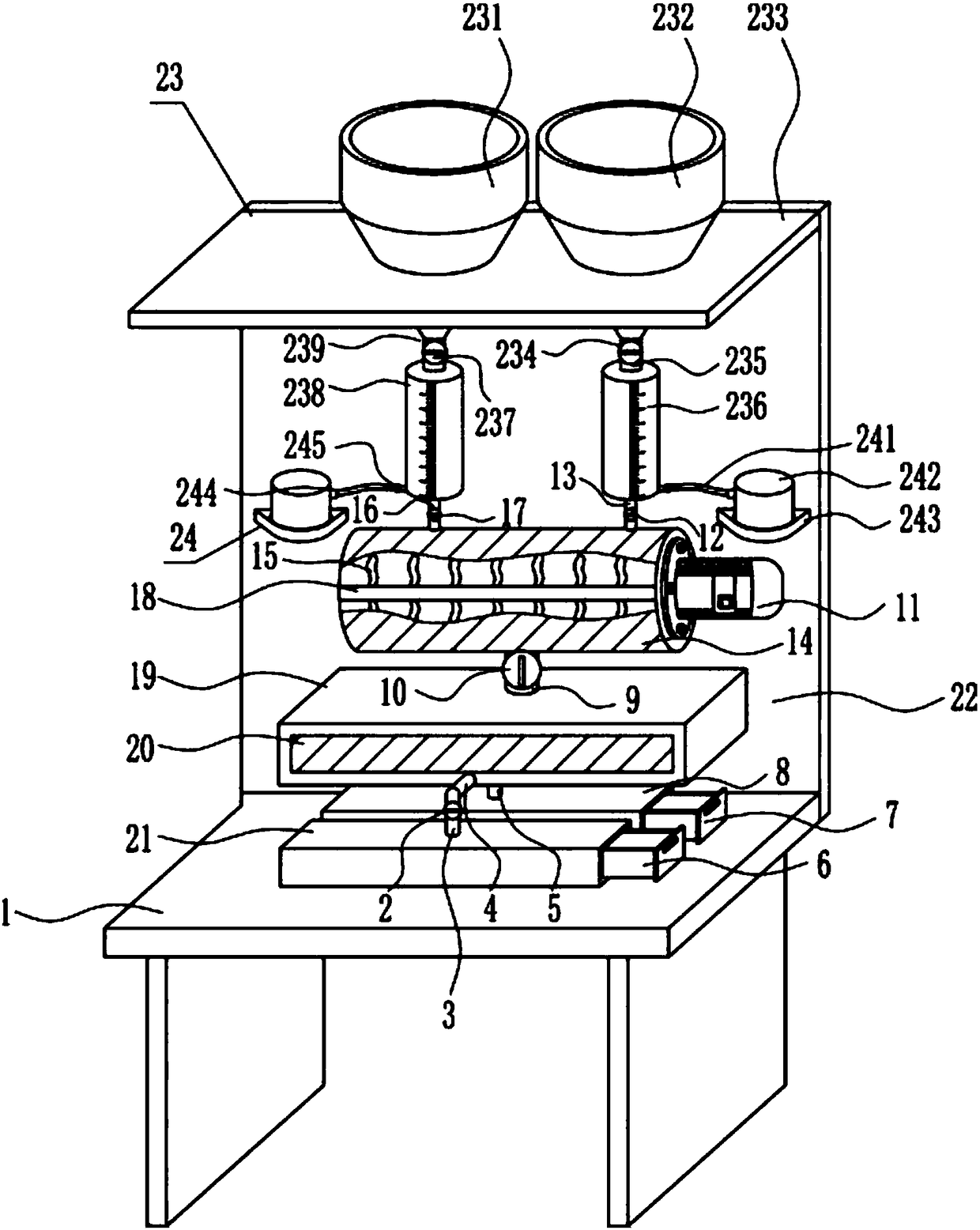

Rare earth oxide extraction equipment

InactiveCN108251641AFully fusedEasy extractionSolvent extractionProcess efficiency improvementRare earthEquipment use

Owner:吴彬

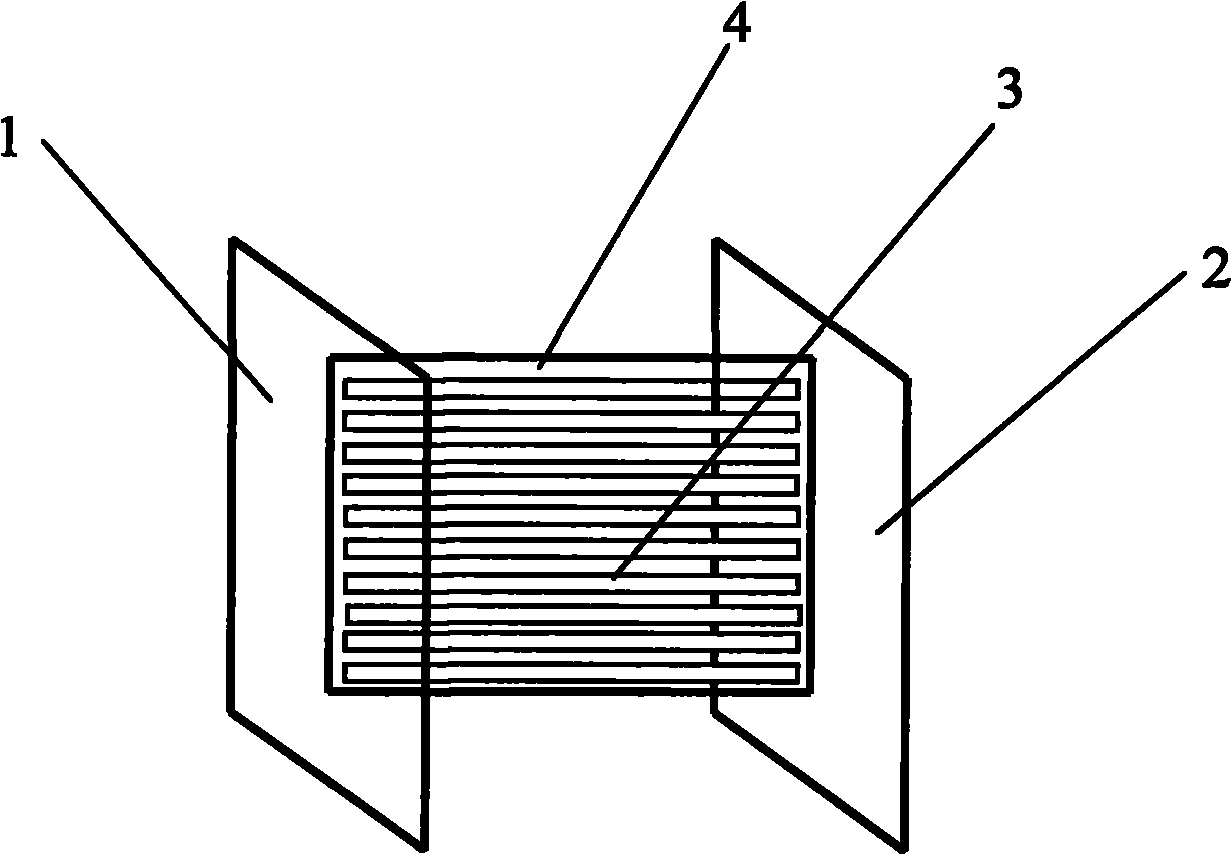

Aeration device

PendingCN111792739AExtended stayFully fusedWater treatment parameter controlSpecific water treatment objectivesEnvironmental engineeringMechanical engineering

The invention discloses an aeration device which comprises an aerator and a bubble supporting and guiding mechanism, the aerator comprises an air outlet, the bubble supporting and guiding mechanism istransversely arranged, the bubble supporting and guiding mechanism comprises a bubble inlet and a bubble outlet, and the bubble inlet is communicated with the air outlet. By additionally arranging the bubble supporting and guiding mechanism, after being treated by the aerator, bubbles are supported and guided by the bubble supporting and guiding mechanism and finally emerge from the water surface, so that the residence time of the bubbles in the water body is prolonged, oxygen in the bubbles has sufficient time to be dissolved in the water body, and the oxygen dissolving efficiency is effectively improved.

Owner:FOSHAN KINGXUNENG COLD CHAIN TECH CO LTD

Steel rail three-wire consumable nozzle electroslag welding device

The invention belongs to the related technical field of profile welding, and discloses a steel rail three-wire consumable nozzle electroslag welding device. The welding device comprises a wire feedingmechanism, an electroslag welding machine, a water cooling copper mold and three consumable nozzles; the water cooling copper mold is used for being attached to steel rails to be welded during use, and used for bearing a welding slag pond and a metal molten pool; the electroslag welding machine is electrically connected to a welding wire, conveyed to the consumable nozzles, by the steel rails andthe wire feeding mechanism, the consumable nozzles are used for guiding the welding wire to enter the welding slag pond, the wire feeding mechanism is used for adjusting the feeding-in speed and direction of the welding wire, the three consumable nozzles are parallel, during use, two consumable nozzles are located on rail bottoms on the two sides of the steel rails, and are used for welding the two sides of the bottoms of the steel rails, and the remaining consumable nozzle is located in the gap between two steel rails to be welded, and is used for welding the rail bottom middles, the rail webs and the rail heads. The welding device is higher in welding efficiency, shaping after welding is easy, and the device can be effectively applied to the actual welding of the steel rails, and the adaptation is good.

Owner:HUAZHONG UNIV OF SCI & TECH

Closed multi-stage water curtain desulfurization system

ActiveCN104888594BImprove desulfurization effectFully fusedDispersed particle separationFlue gasWater resources

The invention discloses a closed multi-stage water curtain desulfurization system, which includes a boiler, a tower, and a bracket. The upper part of the cylinder is provided with a circulating water spray pipe, one side of the tower is provided with a smoke exhaust channel, and a smoke exhaust port is provided on the smoke exhaust channel; the upper part of the tower is provided with a demister, and the demister A water diversion plate is set under the device, and a column is set in the middle of the tower, and the column is provided with more than two levels of water curtain caps arranged at intervals from top to bottom, on both sides of the inner wall of the tower More than two layers of water collecting trays are arranged at intervals from top to bottom, and a sewage outlet is provided at the bottom of the tower, and the sewage outlet is connected to a sewage treatment pool. Ensure that the flue gas of the boiler can meet the emission standards and have high desulfurization efficiency, and at the same time realize the decontamination of desulfurized sewage and the recycling of water resources, saving water resources.

Owner:梁山旭洋无烟尘节能环保设备有限公司

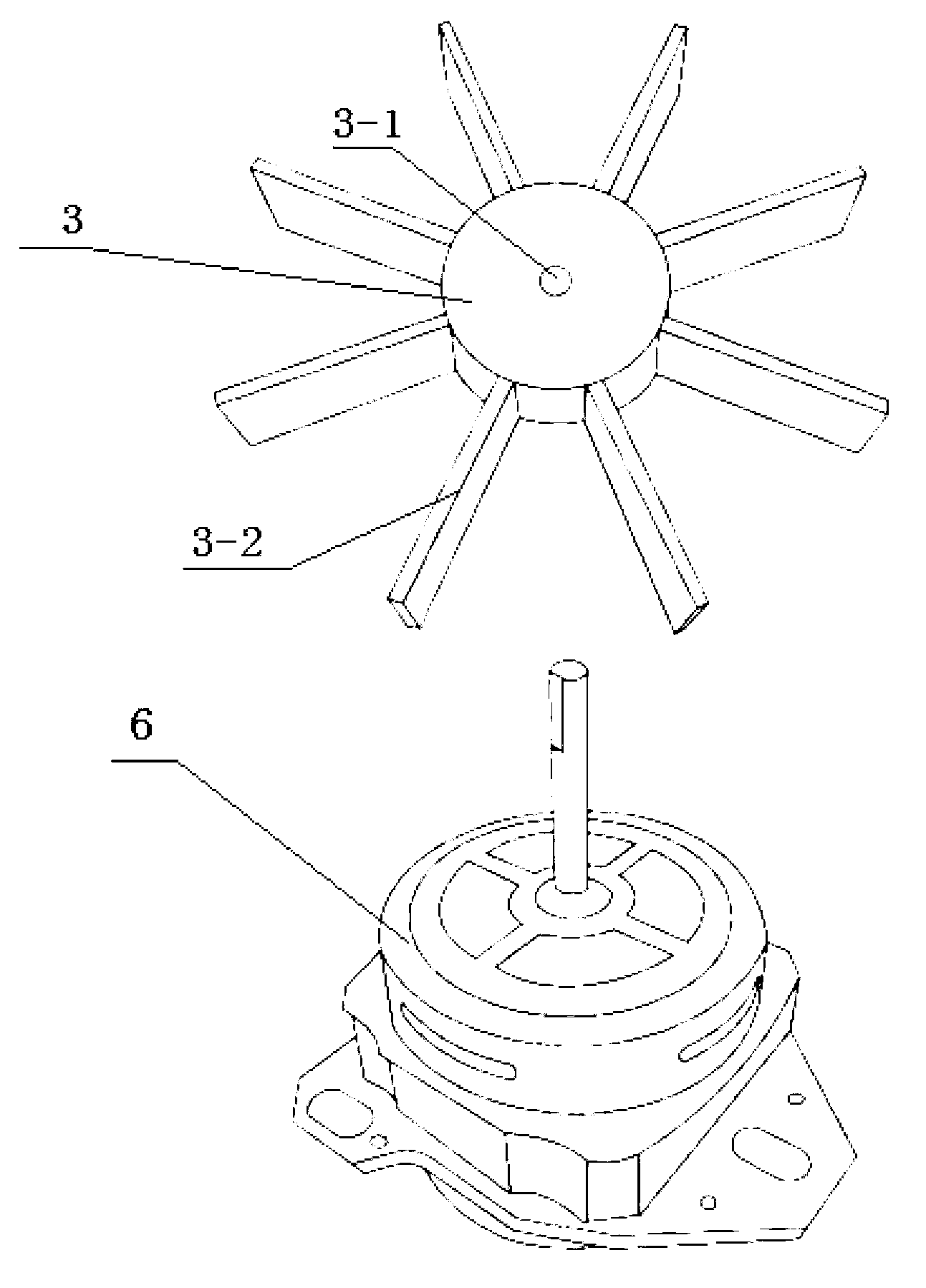

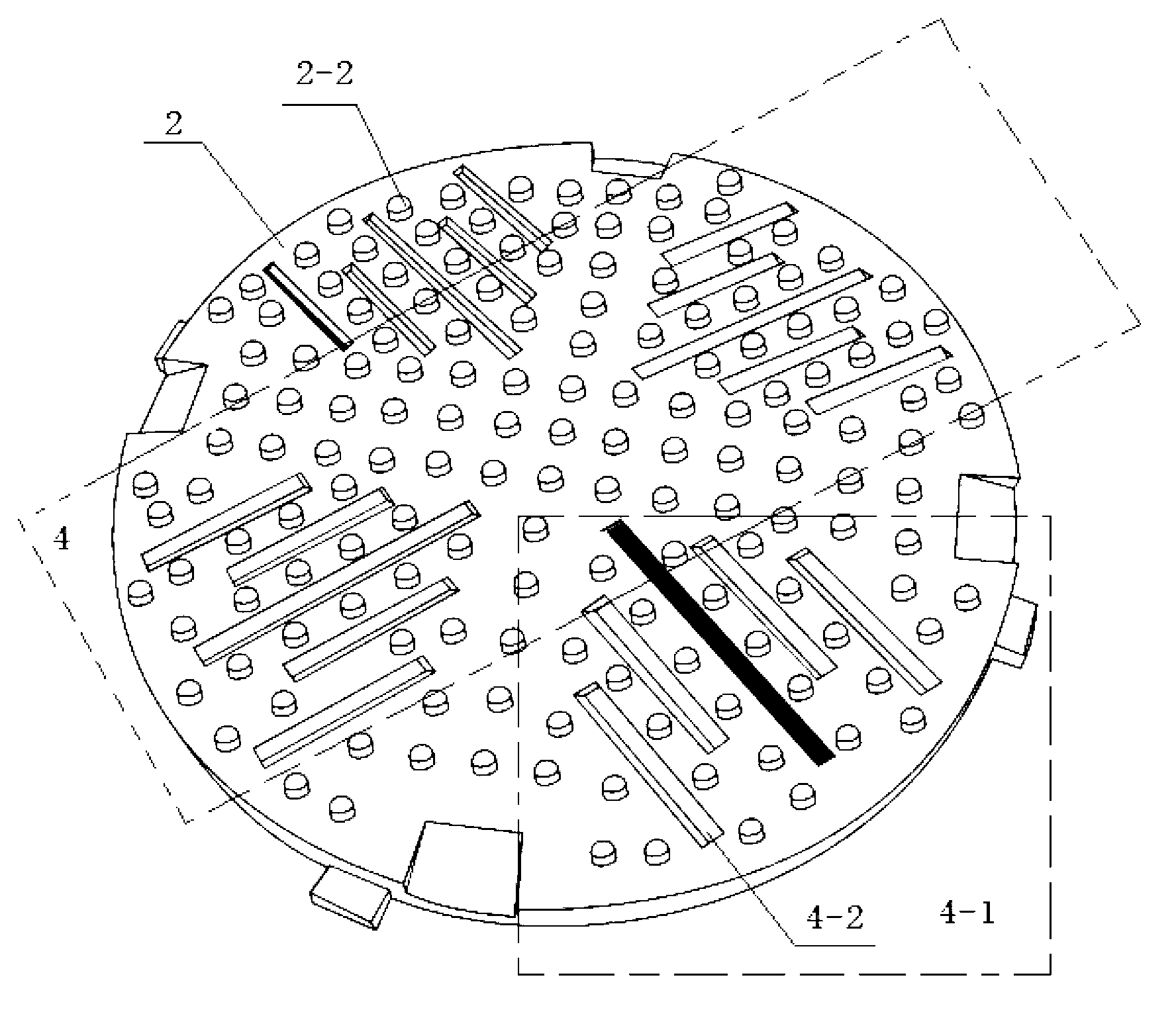

Water circulation device as well as water circulation simulated manual washing device and working method thereof

ActiveCN102995348BAchieve low temperature instantReduce usageOther washing machinesControl devices for washing apparatusWater wheelWater flow

The invention relates to a water circulation device. The water circulation device comprises a shell, a waterflow variation cover which is arranged on the top of the shell and a rotary water wheel which is arranged in the shell, wherein the rotary water wheel and the waterflow variation cover are coaxially arranged, and the rotary water wheel is alternated between clockwise rotation and anticlockwise rotation; the rotary water wheel comprises a middle shaft and a plurality of blades which are fixedly arranged on the middle shaft; a plurality of pairs of guide slots are formed on the waterflow variation cover, each pair of guide slots comprises two groups of guide slots which are symmetrically arranged, and the guide direction of the two groups of guide slots which are symmetrically arranged are the same; and the guide directions of the two groups of guide slots which are arrayed adjacently are opposite. The invention further discloses a water circulation simulated manual washing device and a working method thereof. A motor is utilized to drive the rotary water wheel so as to alternatively suck and discharge waterflow, so that water forms circulation waterflow with appropriate strength in a washing container and forms netty high-speed curved waterflow above the waterflow variation cover. The zero wear of clothes is actually realized during the clothes washing process.

Owner:李守林

Lycium barbarumL. and flos chrysanthemi juice non-dairy cream preparation method

InactiveCN107047803ARetain activityReservation of validityEdible oils/fats ingredientsEdible oils/fats production/working-upFlosActinidia

The invention discloses a lycium barbarumL. and flos chrysanthemi juice non-dairy cream preparation method. The preparation method is characterized in that 1) a product formula is prepared from materials in (%,w / w): 30.0 to 45.0 of corn oil, 5.0 to 10.0 of palm oil, 10.0 to 20.0 of lycium barbarum polysaccharide, 5.0 to 15 of actinidia chinensis Planch normal juice, 3.0 to 7.0 of white sugar, 0.5 to 2.0 of edible salt, 5.0 to 10.0 of skim milk powder, 0.05 to 0.2 of diglycerate, 0.05 to 0.3 of lecithin, 0.01 to 0.03 of potassium sorbate, 0.01 to 0.03 of citric acid, 0.5 to 1.0 of carrageenan, 1.0 to 2.0 of sodium caseinate and the rest of flos chrysanthemis juice to 100; 2) the lycium barbarum polysaccharide is extracted; (3) the flos chrysanthemis juice is prepared; 4) the actinidia chinensis Planch normal juice is prepared; 5) a water phase is prepared; 6) an oil phase is prepared; 7) blending emulsification is performed; 8) shock chilling formation is performed. The lycium barbarumL. and flos chrysanthemi juice non-dairy cream manufactured by the preparation method disclosed by the invention can overcome side effects of trans-fatty acid, can effectively reduce low density lipoprotein and improve high density lipoprotein in human blood, has health-care functions of repelling wind, clearing heat, clearing liver, improving vision, detoxifying and eliminating inflammation and is full of fruit fragrance.

Owner:YANCHENG DINGYI FOOD

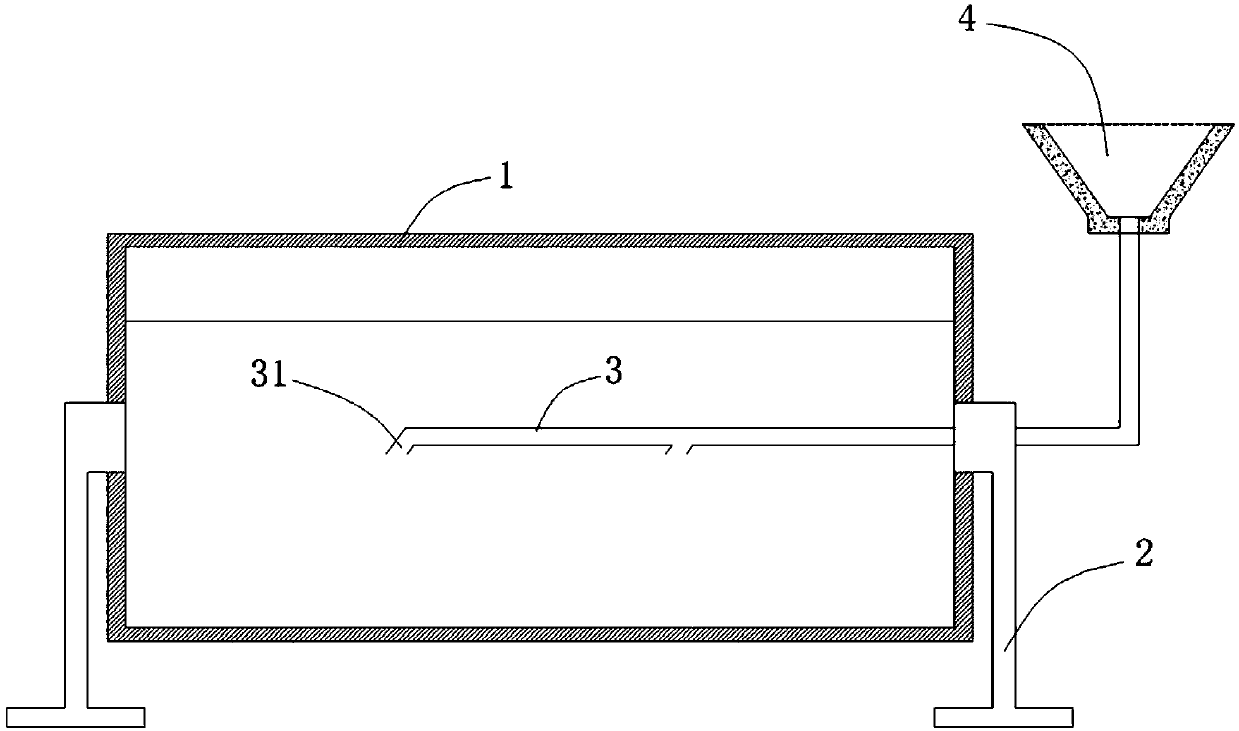

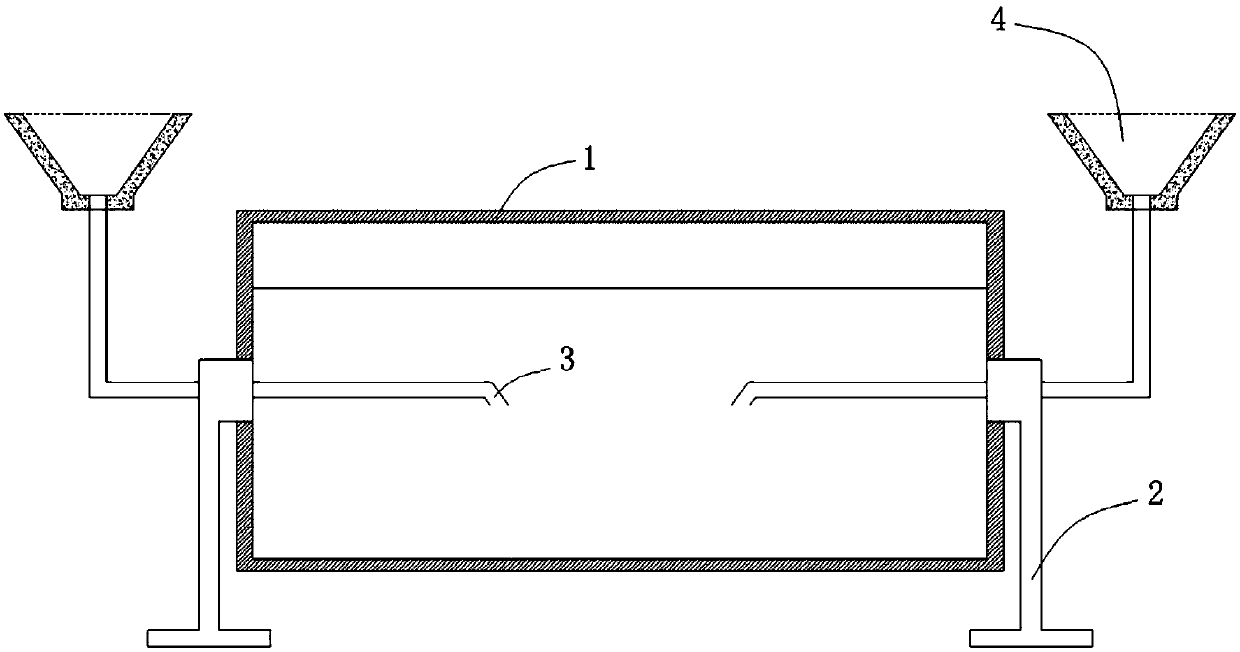

Machining method of bi-metal composite roller sleeve and bi-metal composite roller sleeve

The invention discloses a machining method of a bi-metal composite roller sleeve. The machining method of the bi-metal composite roller sleeve includes the following steps that (a), an outer steel mold prepared in advance is erected on a centrifugal rotating mechanism, the axis of the outer steel mold is in a horizontal state, a casting nozzle stretches into the outer steel mold from one end of the outer steel mold, the casting nozzle moves in the axial direction in the outer steel mold manipulatively, and the casting nozzle communicates with a casting cup; (b), the centrifugal rotating mechanism is started, the rotating speed of the centrifugal rotating mechanism is set to be 750-1200 r / min, and the centrifugal rotating mechanism drives the outer steel mold to do the rotating movement; and (c), a roller sleeve outer layer of the composite roller sleeve is firstly cast, after the roller sleeve outer layer is cast into the designed thickness, cooling is performed for 3-5 min, then a roller sleeve inner layer of the composite roller sleeve is cast, and casting stops after the roller sleeve inner layer reaches the designed thickness. The invention further discloses the bi-metal composite roller sleeve. Due to the fact that centrifugal casting is adopted, the cast roller sleeve outer layer and the cast roller sleeve inner layer are better in compactness, especially when the rollersleeve inner layer is cast in the second stage, due to the centrifugal force, molten metal of the roller sleeve inner layer is thrown to the roller sleeve outer layer, the proportion and the depth forthe roller sleeve inner layer molten metal to permeate into the roller sleeve outer layer are further improved, and therefore the roller sleeve outer layer and the roller sleeve inner layer are combined better.

Owner:湖南四昉新材料有限公司

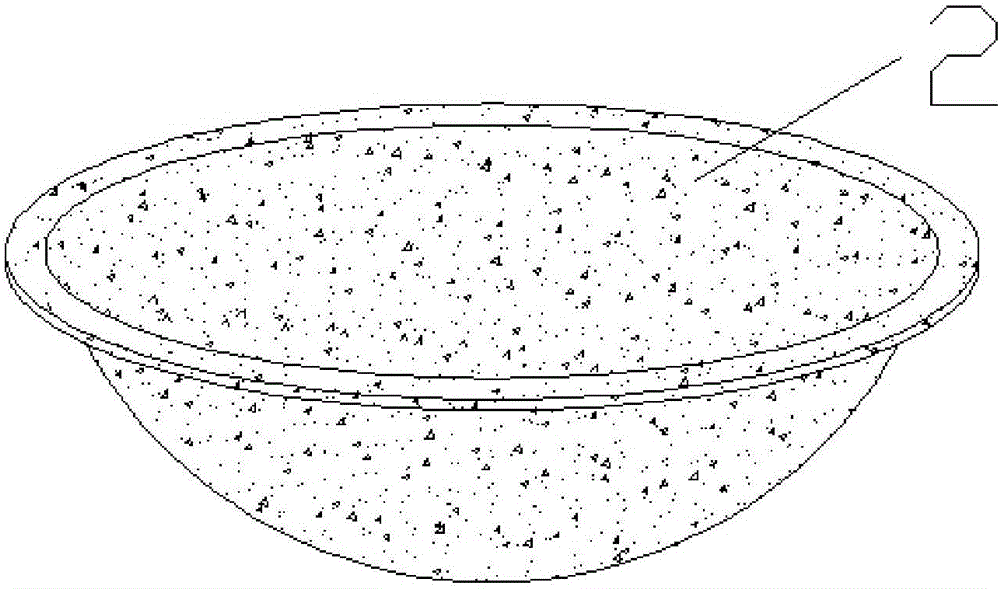

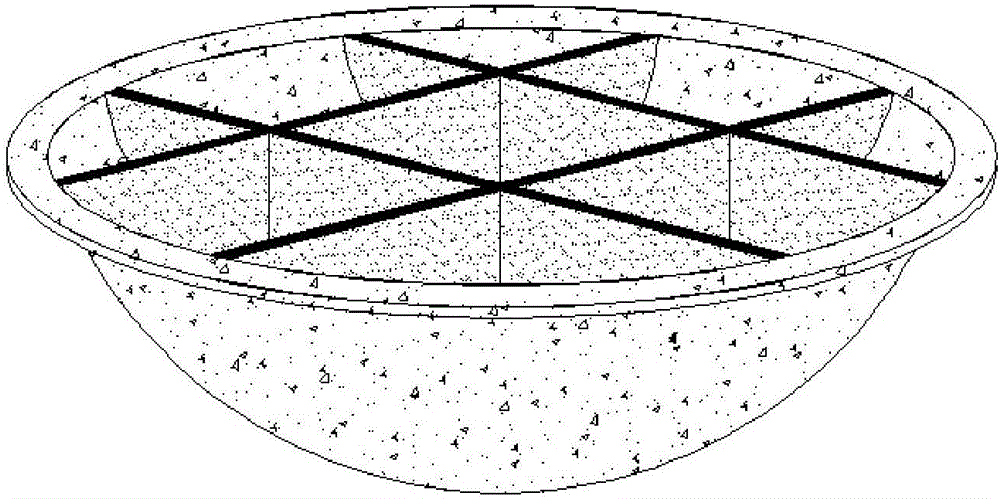

Method for casting multi-box hot pot

The invention provides a method for casting a multi-box hot pot, and belongs to the technical field of iron pot casting. According to the hot pot, partition plates are cast at first, and then the partition plates and a pot body are in melting combination to achieve seamless connection. The method includes the main steps that (1) the partition plates are formed; (2) the partition plates are placed into a mold to be polished; (3) the pot body and the partition plates are combined; and (4) cooling molding is performed. By the adoption of the method, the hot pot is made of cast iron which is natural, environmentally friendly, safe and stable in performance, the hot pot is divided into a plurality of small boxes through the partition plates, and the partition plates and the pot body are subjected to casting molding directly without welding; hence, hazardous substances at the welding position can be prevented from entering human bodies along with the hot pot, corrosion of the connecting portion between the partition plates and the pot body due to cooking the hot pot for a long time is prevented, the phenomenon of being tainted by other odors between all the small boxes is effectively avoided, and hot pot quality is improved. Moreover, the pot body is separated by the partition plates, each person can use his / her different small boxes, different hot pot materials can be boiled, and therefore the hot pot not only is sanitary but also can be used for boiling different kinds of food at the same time.

Owner:陆川县浦宝铁锅厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com