Closed multi-stage water curtain desulfurization system

A desulfurization system and closed technology, applied in separation methods, disperse particle separation, chemical instruments and methods, etc., can solve the problems of incomplete desulfurization, escape of harmful substances, reduction effect, etc., to achieve outstanding substantive characteristics and improve desulfurization effect. , the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

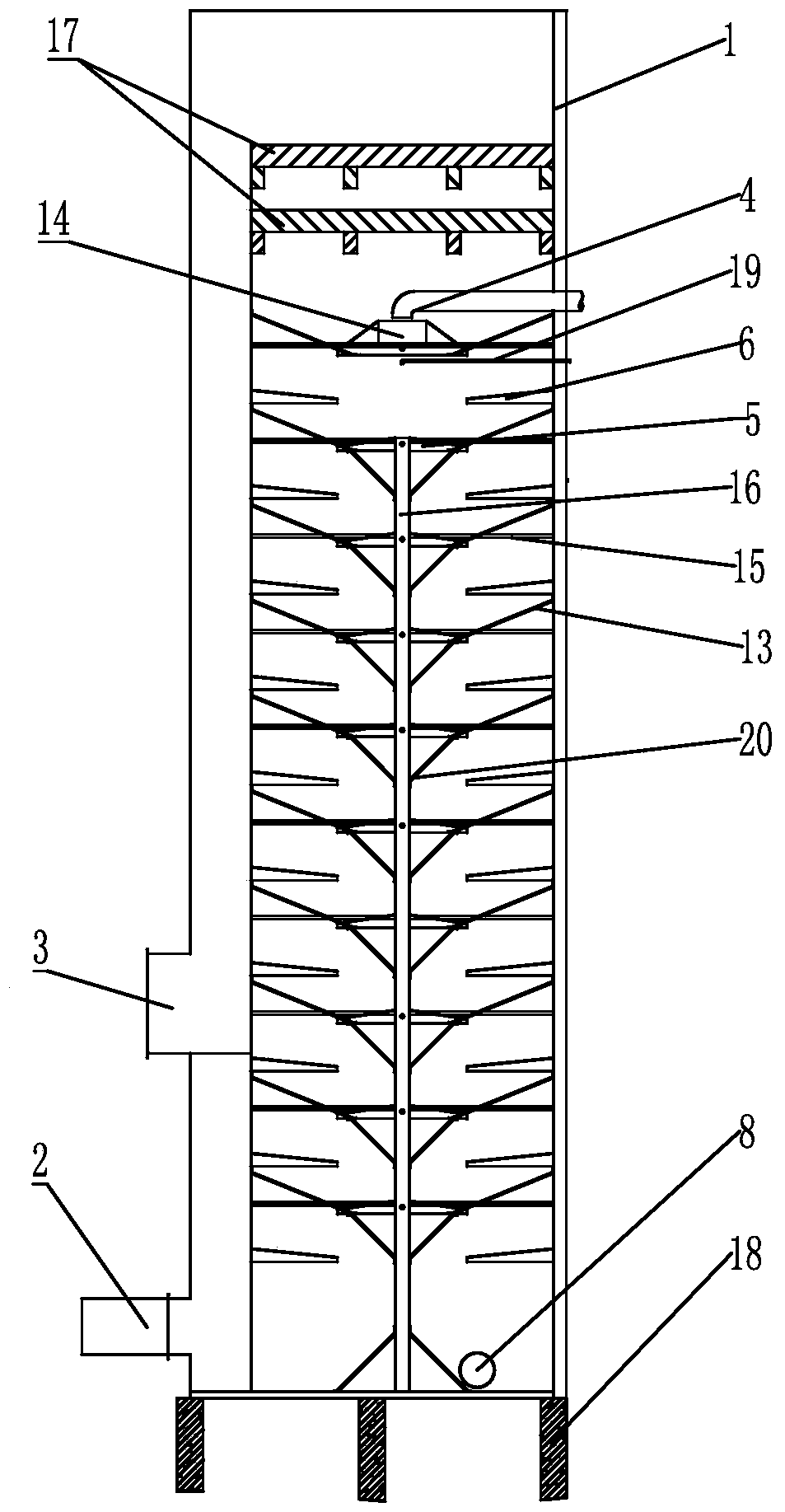

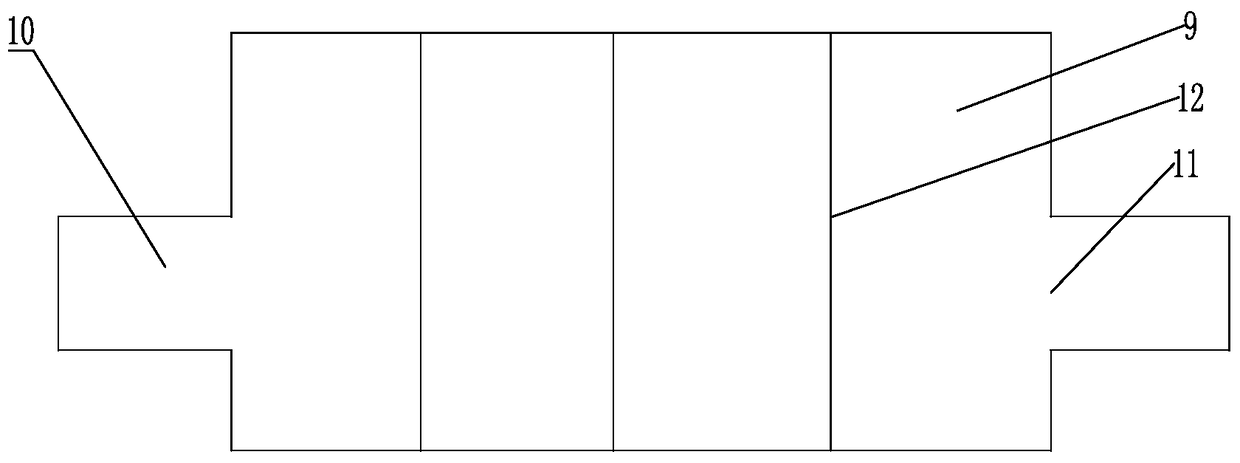

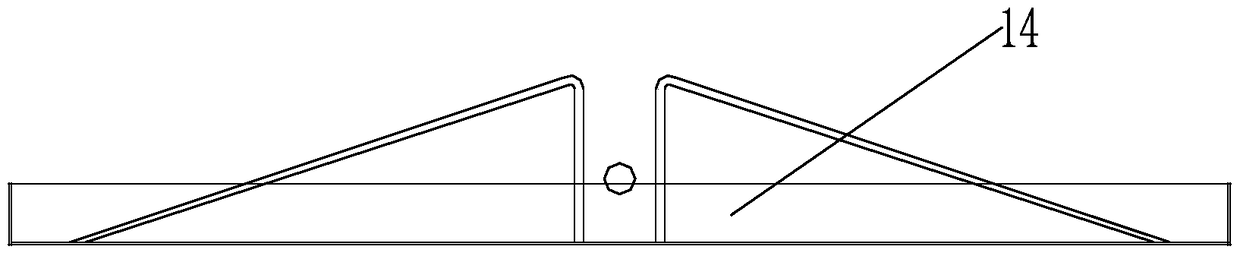

[0028] Such as figure 1 As shown, a closed multi-stage water curtain desulfurization system includes a boiler, a tower tube 1, and a bracket 18. The boiler and the tower tube 1 are connected by pipes. The tower tube 1 is installed on the bracket 18, and the bracket 18 is fixed on the foundation. The lower part of the tower 1 is provided with a smoke inlet 2, and the upper part of the tower 1 is provided with a circulating water spray pipe 4, a smoke exhaust channel is provided on one side of the tower 1, and a smoke outlet 3 is provided on the smoke exhaust channel. 2 It is on the same side as the exhaust port 3 and separated from each other to avoid mixing of flue gas, or flue gas that has not been desulfurized and dust-removed from the exhaust port 3, causing air pollution; a demister 17 is installed in the upper part of the tower 1 , The demister 17 is fixed on the inner wall of the tower 1, the demister 17 can fully absorb the moisture in the flue gas desulfurized by the wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com