Welding groove form and welding process of container adapter tube or blind flange adapter tube

A blind flange, welding groove technology, applied in welding equipment, manufacturing tools, arc welding equipment and other directions, can solve the problem that the welder cannot guarantee the back forming and welding quality, the welding quality is unstable, and the welder's skill requirements are high. Convenient welding torch swing, stable welding quality and small heat input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

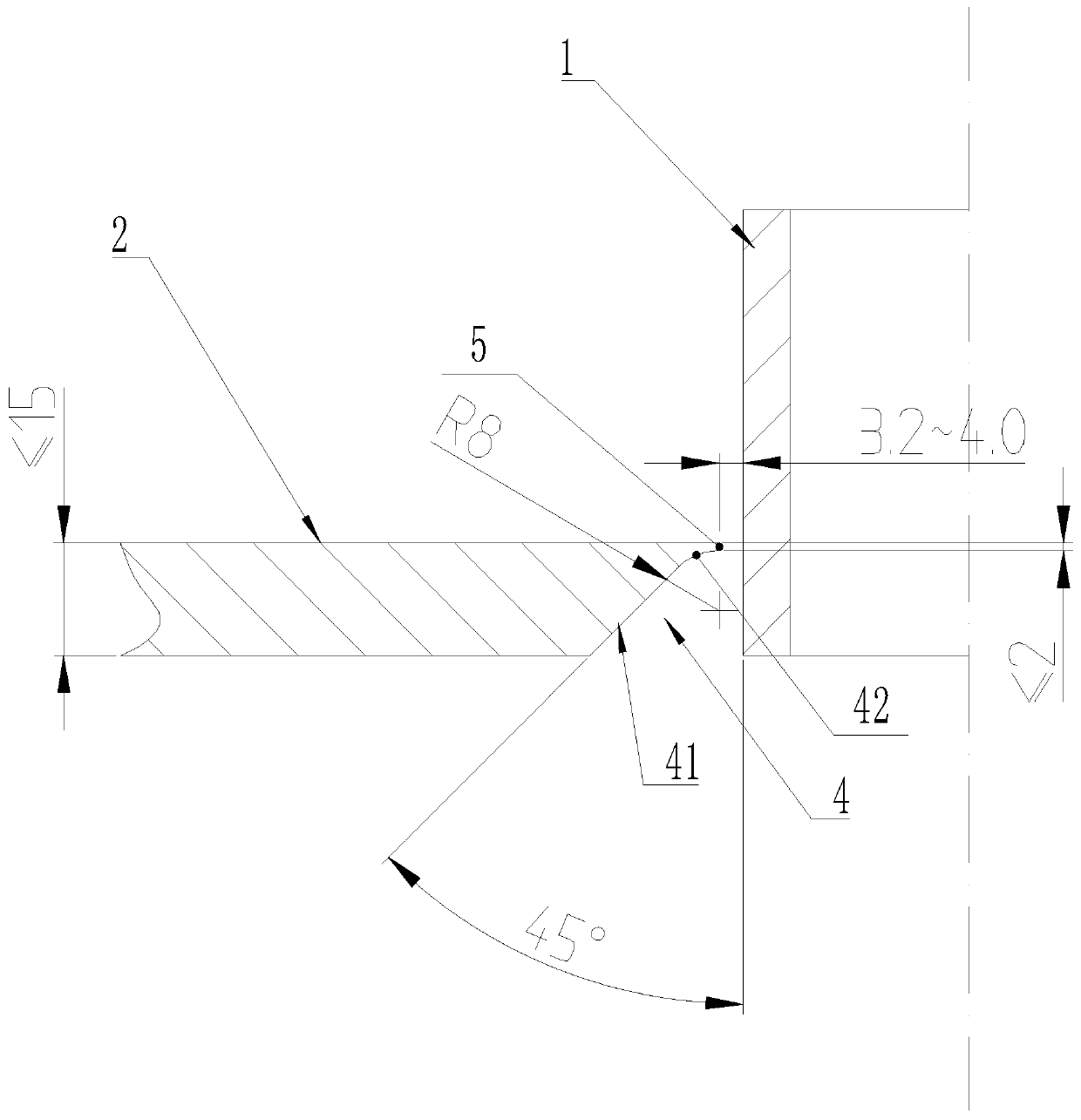

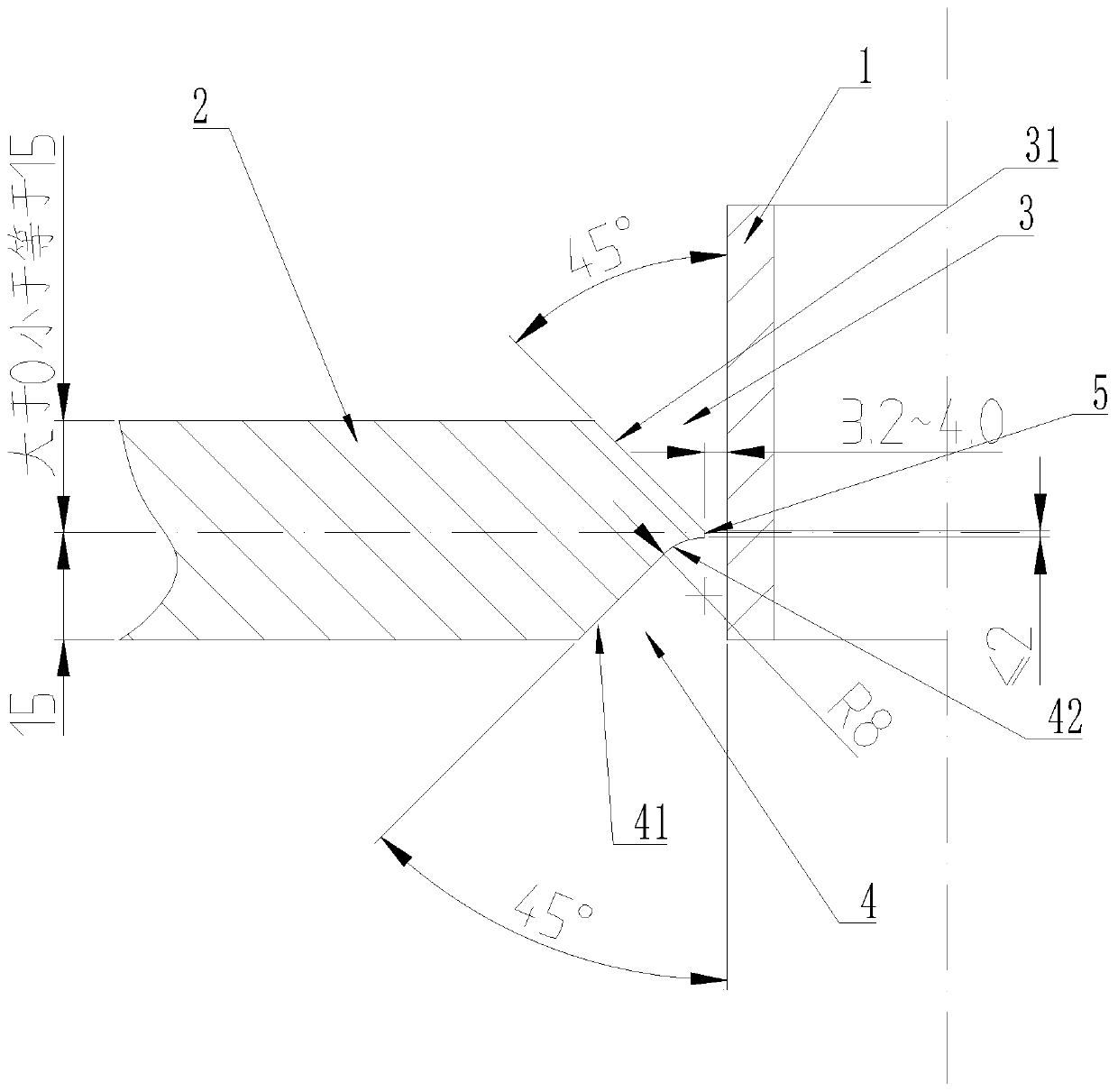

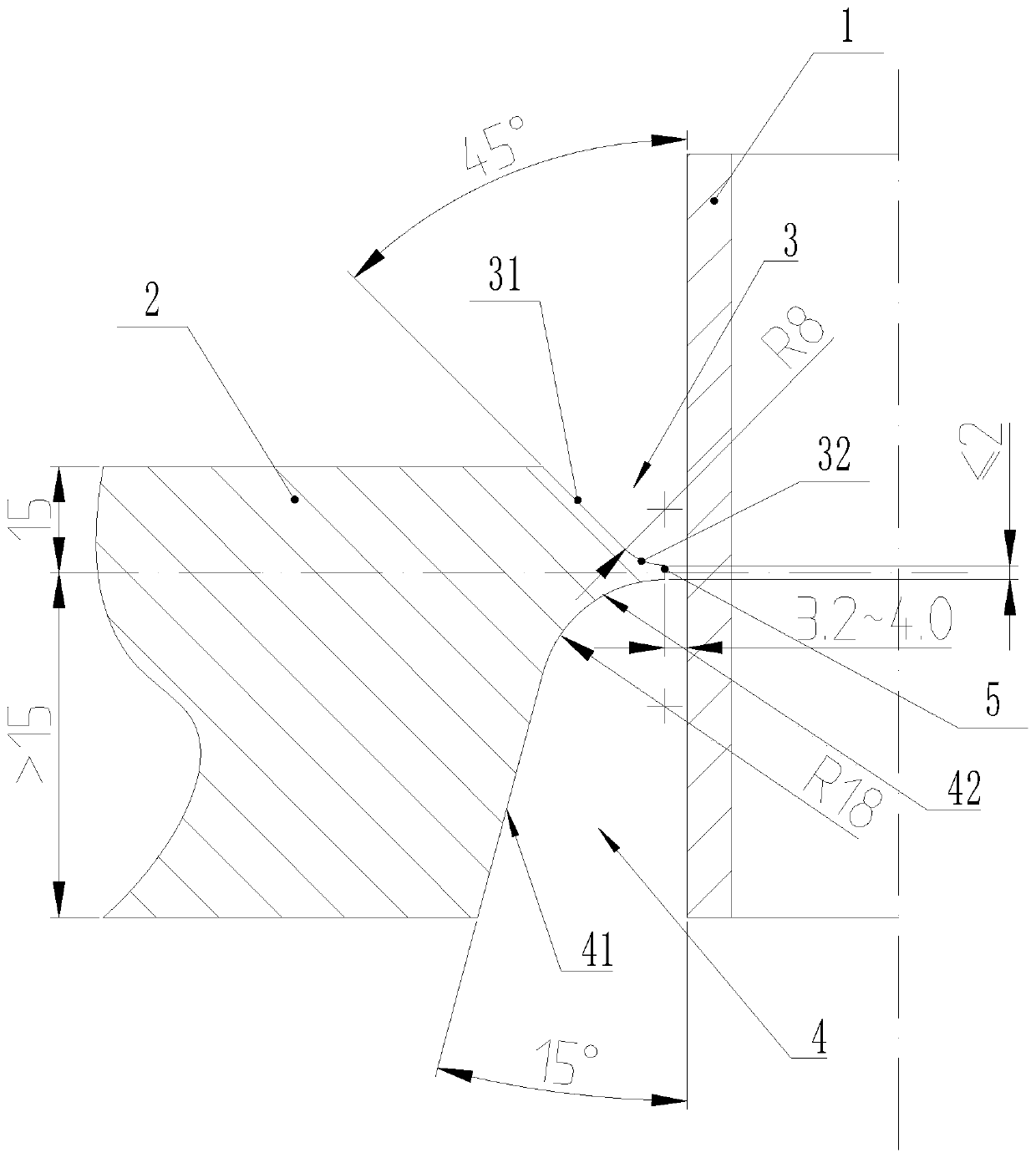

[0060] Such as Figure 1 to Figure 3 As shown, a welding groove form of a container joint or a blind flange joint includes a first workpiece to be welded and a second workpiece 2, the first workpiece is a joint 1, and the second workpiece 2 is a container or blind flange, where figure 1 The upper side of the drawing represents the outside, and the lower side represents the inside, and the second workpiece 2 is provided with a nozzle hole that facilitates the insertion of the nozzle 1. The nozzle 1 is inserted into the nozzle hole and the second workpiece 2 is vertical;

[0061] When the wall thickness of the second workpiece 2 is less than or equal to 15mm, the second workpiece 2 has a J-shaped groove on the inner surface of the nozzle hole. The center line forms an included angle of 45°, the arc surface is set at the root of the J-shaped groove, the arc surface is tangent to the slope, and a blunt edge 5 is passed between the arc surface and the outer surface of the second w...

Embodiment 2

[0069] A welding process for a container joint or a blind flange joint, comprising the following steps:

[0070] A. Preparation before welding, including the following sub-steps:

[0071] a1) Selection tool: choose a 75° argon arc welding torch with a diameter of 40-50mm 2 Hand-held cerium tungsten electrode with 3.2-4m diameter and 2.0mm or 2.4mm diameter, the tip of the cerium tungsten electrode is processed into a truncated conical shape with a taper of 35°-45°, and the diameter of the small circle of the truncated cone is 0.8-1.0mm. The protruding length of the porcelain nozzle relative to the argon arc welding torch is 6-8mm; choose No. 6 porcelain nozzle; choose straight handle hand arc welding tongs, diameter 40-60mm 2 Handle wire 3.2-4m;

[0072] a2) Acceptance inspection of tools: check whether the DC argon arc welding torch and the measuring instruments of the argon gas flowmeter have been calibrated and are within the validity period, check whether the argon gas p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com