Hot wire welding device

A technology of hot wire welding and welding equipment, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of inability to compare the deposition rate and the heat is not good, achieve a considerable deposition speed, reduce pores, and deposit rate increase effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

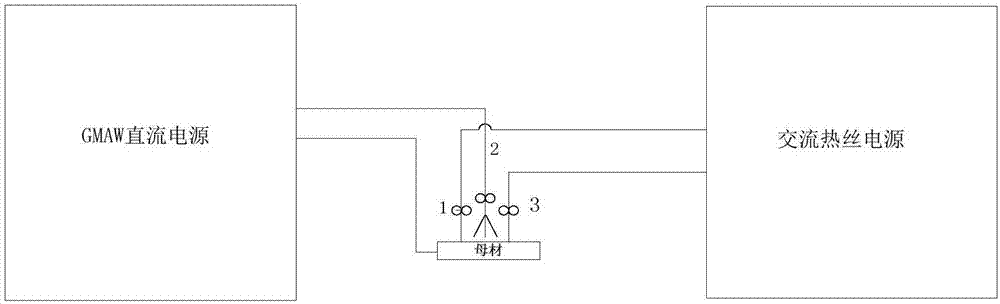

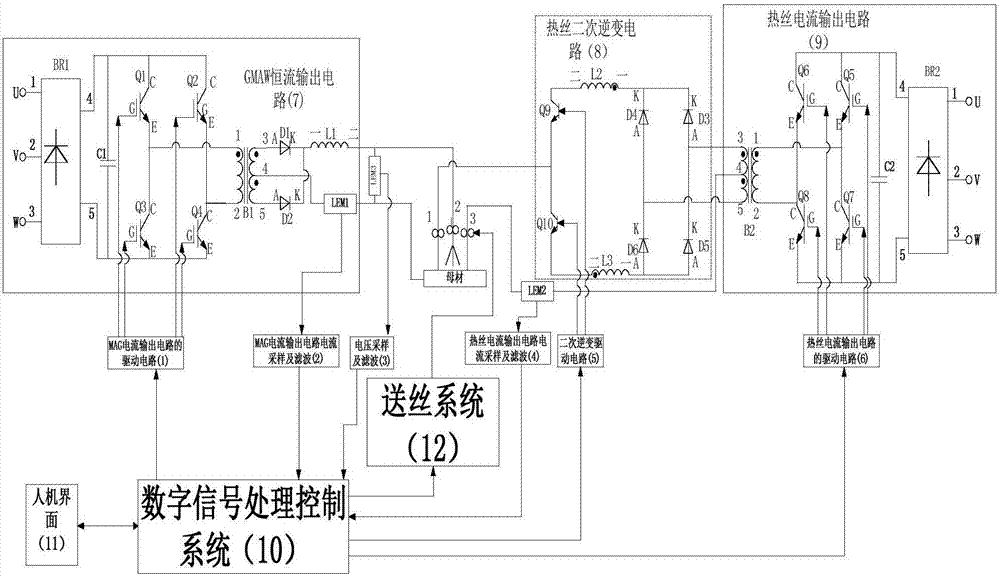

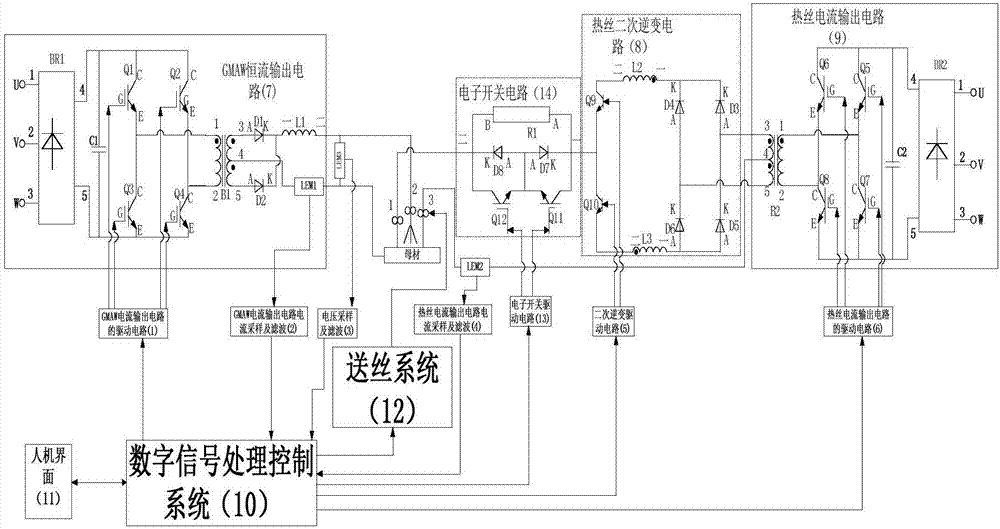

[0031] The working principle of the single hot wire welding equipment and the double hot wire welding equipment are the same. Taking the schematic diagram of the double hot wire equipment as an example, the present invention will be further described in detail in combination with the description of the drawings and specific implementation methods:

[0032] The system uses the GMAW welding arc as the main arc, and the alternating current flowing through the two hot wires controls the swing of the GMAW arc. The main arc is continuously conducted between the base metal and the GMAW welding torch. When the gap exists and switches back and forth, the arc swing can be realized under the influence of electromagnetic force. When the three welding torches work at the same time, the deposition efficiency can be improved and high-efficiency welding can be realized. Since the length of the molten pool can be adjusted, compared with single-melting electrode welding, this process can reduce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com