Filler wire argon tungsten arc process of super nickel/NiCr stacking compound material

A technology of argon tungsten arc welding and composite materials, which is applied in the direction of arc welding equipment, welding/welding/cutting items, manufacturing tools, etc., to achieve the effect of beautiful weld shape, good manufacturability, and non-porous interface fusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

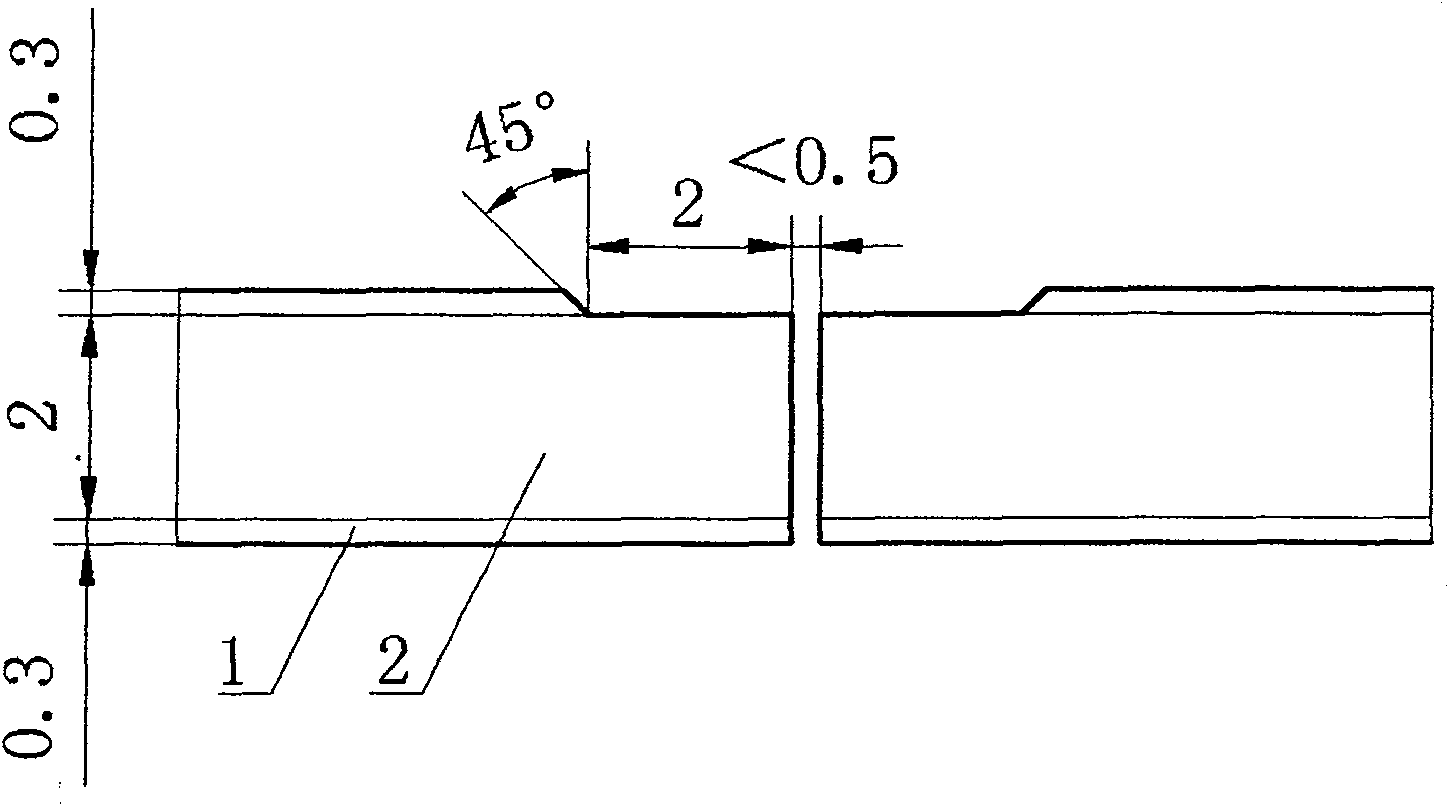

[0029] Butt-filled wire tungsten arc welding of Super-Ni / NiCr laminated composite materials with a test plate size of 100mm×100mm×2.5mm. Take two laminated composite materials of the same size and specifications, butt weld them, and do not open grooves at the joints.

[0030] Before welding, the pure nickel clad layer at the welded joint of the Super-Ni / NiCr laminated composite material is machined off, and processed into such as figure 1 Connector form shown. It is required that the joints to be processed should be flat and the base layer should be exposed, and the base layer should be polished with sandpaper until a metallic luster appears. Cr25-Ni13 alloy welding wire with a diameter of 2.0mm is used as the filler metal, and the surface of the welding wire is polished with sandpaper before welding. The two processed Super-Ni / NiCr laminated composite test plates are assembled horizontally at the joints, and the assembly gap is less than 0.5mm. Tungsten argon arc welding w...

Embodiment 2

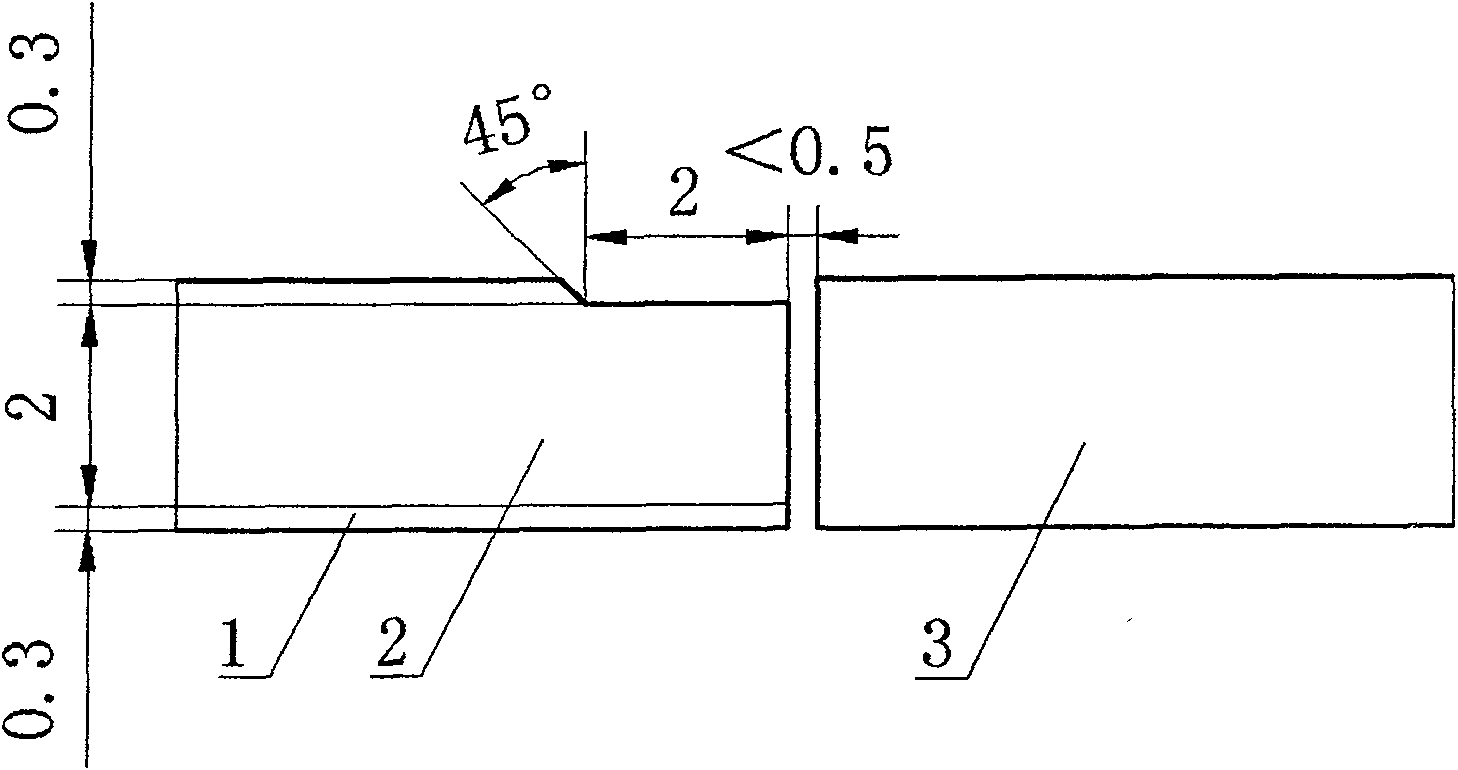

[0034] Filled tungsten argon arc welding of Super-Ni / NiCr laminated composite material and 1Cr18Ni9Ti austenitic stainless steel. The size of the Super-Ni / NiCr laminated composite test plate is 80mm×80mm×2.5mm, and the size of the 1Cr18Ni9Ti austenitic stainless steel test plate is 80mm×80mm×2.5mm. The two plates are butt welded, and no groove is made at the joint.

[0035]Before welding, the pure nickel clad layer at the welded joint of the Super-Ni / NiCr laminated composite material is machined off, and processed into such as figure 2 Connector form shown. It is required that the joints to be processed should be flat and the base layer should be exposed, and the base layer should be polished with sandpaper until a metallic luster appears. Cr25-Ni13 alloy welding wire with a diameter of Φ2.5mm is used as the filler metal, and the surface of the welding wire is polished with sandpaper. The processed Super-Ni / NiCr laminated composite material is fixedly assembled with the 1C...

Embodiment 3

[0039] Filled tungsten argon arc welding of Super-Ni / NiCr laminated composite material and 1Cr18Ni9Ti austenitic stainless steel.

[0040] (1) Before welding, the pure nickel clad layer at the joint of super nickel / NiCr laminated composite material to be welded is machined off, and the processed place is required to be flat, the base layer is exposed, and the base layer is polished with sandpaper until a metallic luster appears;

[0041] (2) Use Cr-Ni alloy welding wire with a diameter of 2.5mm as the filler metal, and polish its surface with sandpaper until it reveals a metallic luster;

[0042] (3) Surface treatment of stainless steel joints of butt joints to be welded: acid solution (5% HF aqueous solution and 35% HNO 3 A mixture of aqueous solution) to pickle the joints, rinse with clean water until the surface of the stainless steel joints shows metallic luster until neutral, dry, and set aside; ,spare;

[0043] (4) process the super nickel / NiCr laminated composite mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com