Welding gun swinging device for vertical electrogas welder

A technology of vertical gas-electric vertical welding and swinging device, which is applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of reduced weld strength, intermittent welds, and unfused sidewalls of welds, and achieves mechanical properties. Improve, avoid discontinuity or sudden change, and increase the effect of weld penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

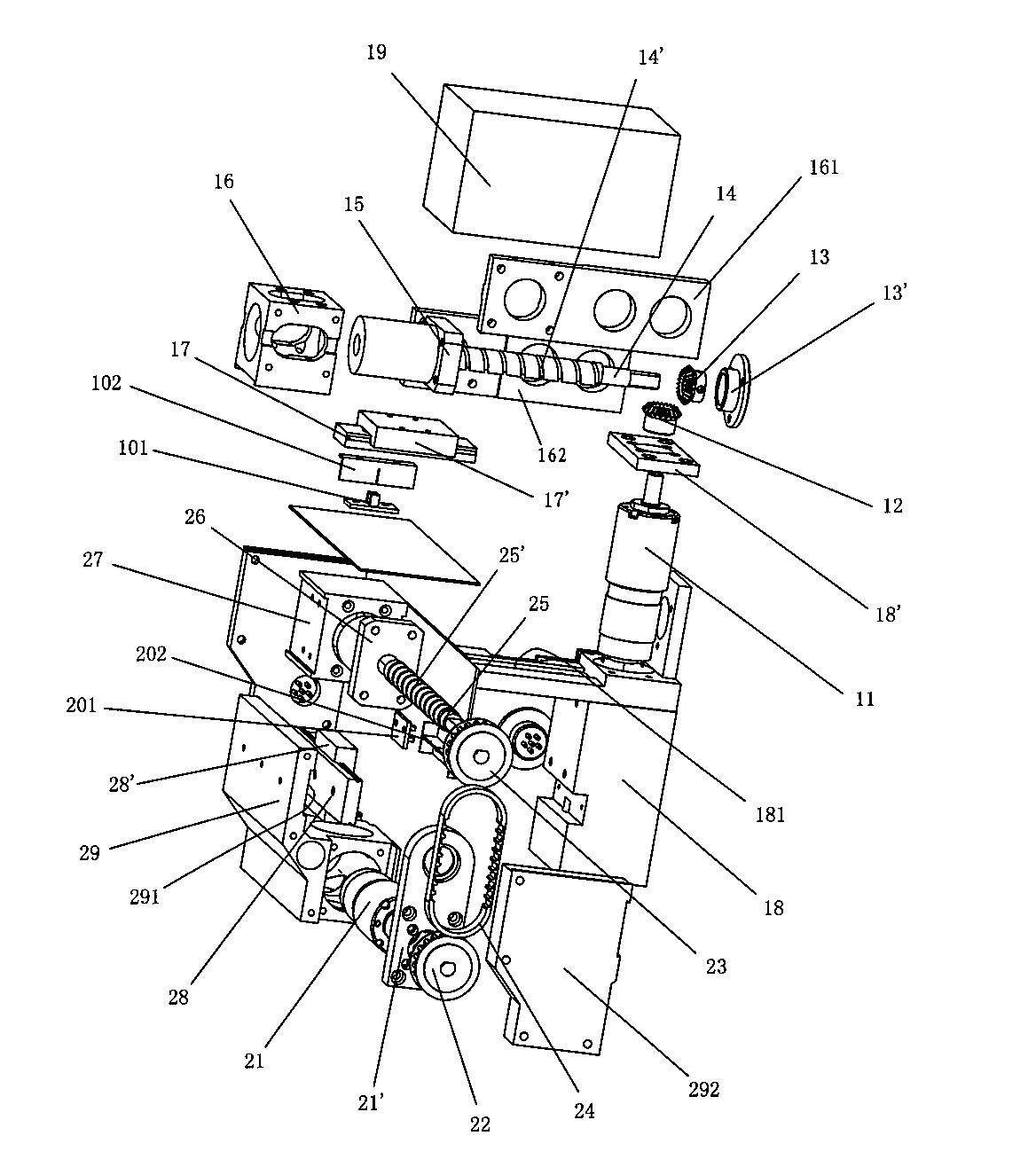

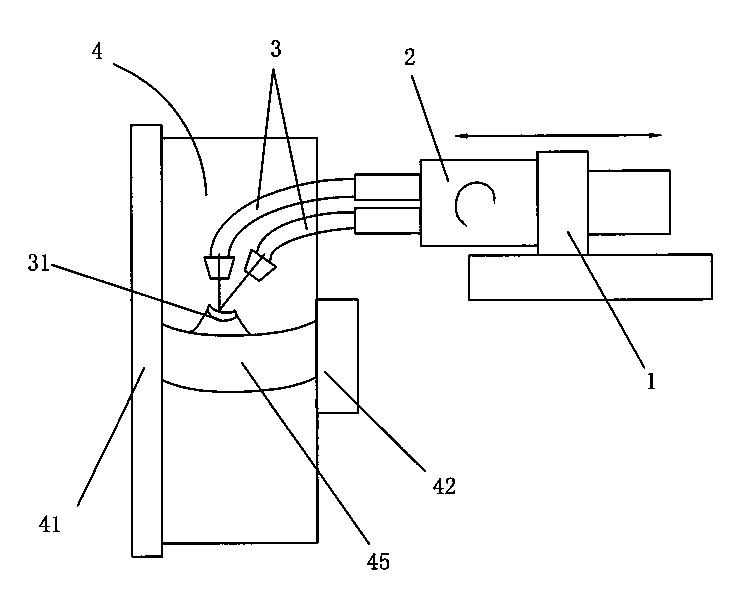

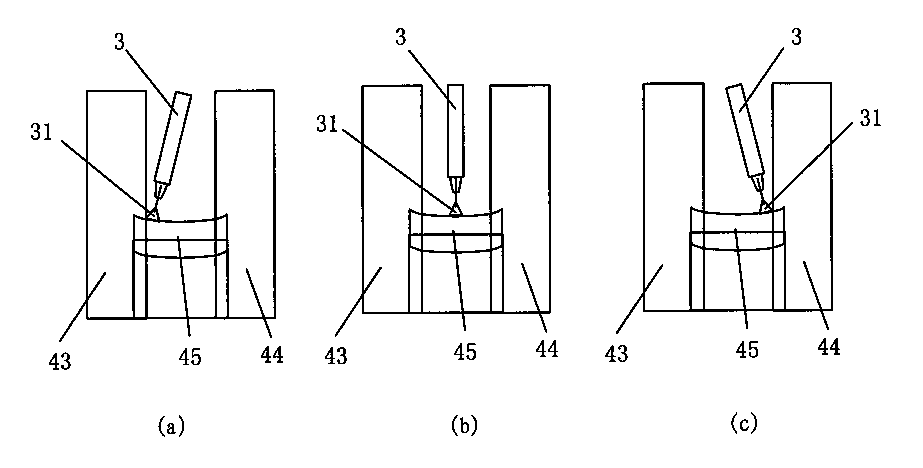

[0018] Please refer to the accompanying drawings Figure 1-4 . In the figure, the horizontal sliding mechanism 1 (the first motor 11, the first gear 12, the second gear 13, the first screw 14, the first screw cover 15, the first screw cover fixing seat 16, the first linear slide rail 17, the first slider 17' and the first fixed seat 18), the sawtooth swing mechanism 2 (the second motor 21, the first step wheel 22, the second step wheel 23, the synchronous pulley belt 24, the second lead screw 25, the second Two lead screw sleeves 26, a second screw cover fixing base 27, a second linear slide rail 28, a second slider 28' and a second fixing base 29).

[0019] As shown in the picture:

[0020] The torch swing device for vertical gas-electric vertical welding according to the present invention includes a horizontal slide mechanism 1 and a sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com