Low-temperature carbon steel valve casting material and manufacturing method thereof

A low-temperature steel and casting technology, applied in the field of low-temperature carbon steel valve casting materials, can solve the problems of time-consuming and laborious, the key process of heat treatment has not been studied in detail, and the valve is not suitable for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

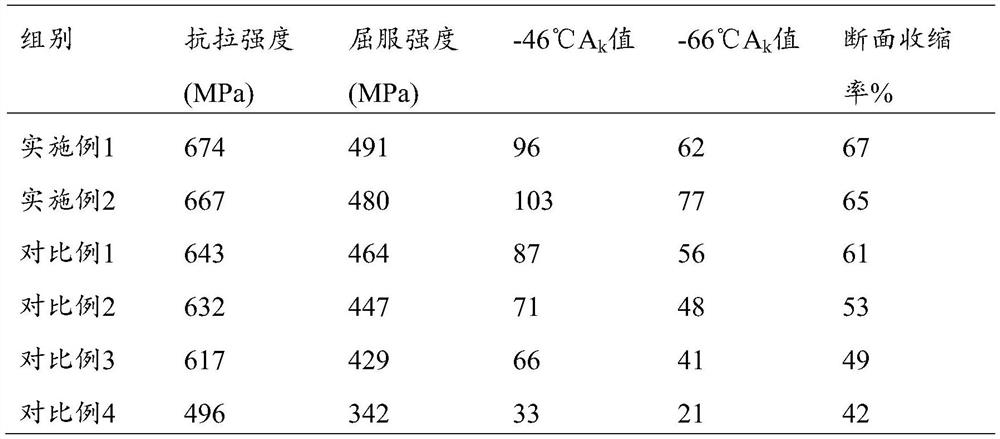

Examples

preparation example 1

[0091] Preparation of Alloyed Composite Carbon Steel Material 1

[0092] (1) Preparation of raw materials:

[0093] S1-1: Prepare a commercially available composite steel composed of LCB steel and LCC steel with a mass ratio of 8:2 as the source of the ferritic low-temperature steel matrix material. The surface is cleaned in advance to remove impurities and the surface oxide layer is polished. After cleaning and drying, the obtained The dry steel body material is about 0.5 tons; wherein, the composition of the LCB steel is: C content is 0.18-0.19%, Si content is 0.4-0.5%, Mn content is 0.8-1.0%, S is about 0.04%, P≤ 0.03%, Ni≤0.30%, Cr≤0.20%, Mo≤0.20%, Cu≤0.20%, V≤0.030% (the total amount of Ni, Cr, Mo, Cu, V is less than 1%), the rest is Fe and unavoidable of impurities. Wherein, the composition of the LCC crude steel is: C content 0.15-0.16%, Si content 0.45-0.5%, Mn content 1.0%, S about 0.04%, P≤0.03%, Ni≤0.250%, Cr≤ 0.20%, Mo≤0.20%, Cu≤0.20%, V≤0.030% (the total amount...

preparation example 2

[0102] Preparation of Alloyed Composite Carbon Steel Material 2

[0103] (1) Preparation of raw materials:

[0104] S1-1: Prepare a commercially available composite steel composed of LCB crude steel and LCC crude steel with a mass ratio of 6:4 as the source of the ferritic low-temperature steel matrix material. The surface is cleaned in advance to remove impurities and the surface oxide layer is polished, and then cleaned and dried. After obtaining about 0.5 tons of dried steel material; wherein, the composition of the LCB steel is: C content is 0.18-0.19%, Si content is 0.4-0.6%, Mn content is 0.8-1.0%, S≤0.03%, P ≤0.03%, Ni≤0.20%, Cr≤0.20%, Mo≤0.20%, Cu≤0.20%, V≤0.02% (the total amount of Ni, Cr, Mo, Cu, V is less than 1%), the rest is Fe and not Avoid impurities. Wherein, the composition of the LCC crude steel is: C content 0.14-0.15%, Si content 0.5-0.6%, Mn content 1.2%, S≤0.03%, P≤0.03%, Ni≤0.20%, Cr≤0.20 %, Mo≤0.20%, Cu≤0.20%, V≤0.030% (the total amount of Ni, Cr, Mo...

Embodiment 1

[0111] A method for preparing cryogenic valve castings, comprising the steps of:

[0112] (1) Casting pouring:

[0113] Adjust the temperature of the alloy liquid in Preparation Example 1 to 1620-1680°C until it is stable and release it from the furnace; after sedation treatment, pour the alloy liquid into a mold to obtain a valve casting at a pouring temperature of 1550-1600°C.

[0114]The casting pouring in this step can adopt conventional pouring means in this field according to the actual situation. When pouring, use hardened water glass sand to cast the mold, and the furnace lining is neutral; if the slagging and deoxidation treatment is not performed in the previous step, the pouring system with slag skimming and turbulent flow can also be used to pour alloy steel in this step. The steel temperature is 1620-1680°C, and it is deoxidized. After the deoxidation is completed, appropriate boron iron can be added to improve the fluidity. Combined with the actual production t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com