Twin-wire vertical electrogas welding system with low welding heat input and welding method

A vertical gas-electric vertical welding and heat input technology, which is applied in welding equipment, welding accessories, arc welding equipment, etc., can solve the problems of inability to adjust welding heat input, reduce material costs, improve impact toughness, improve stability and reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

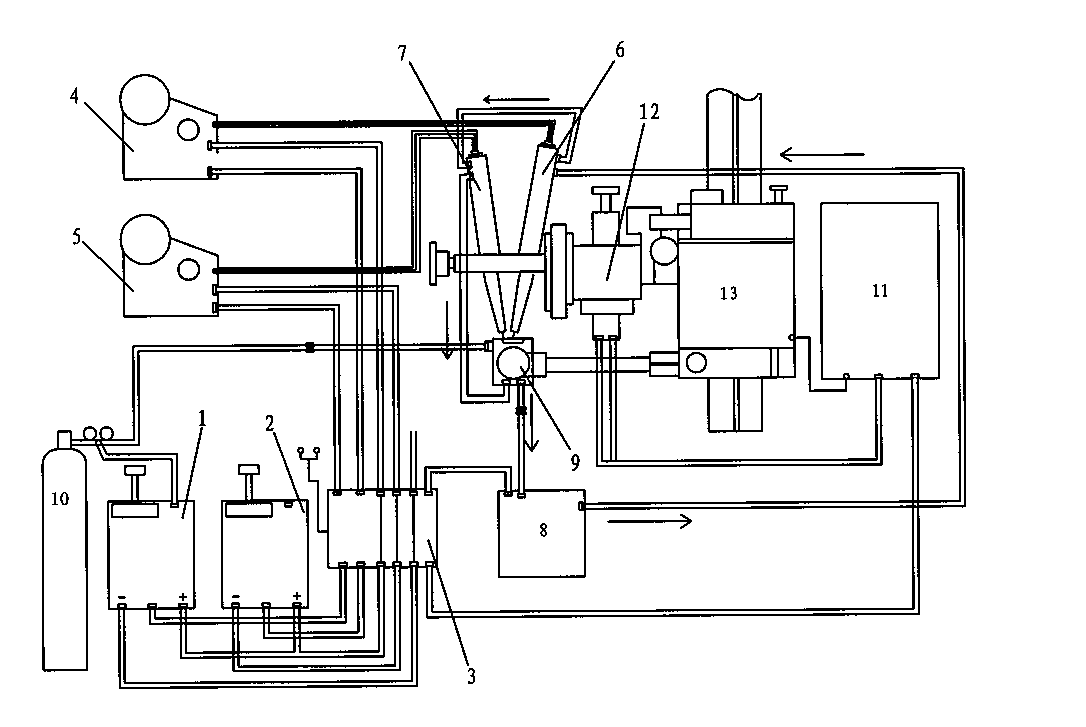

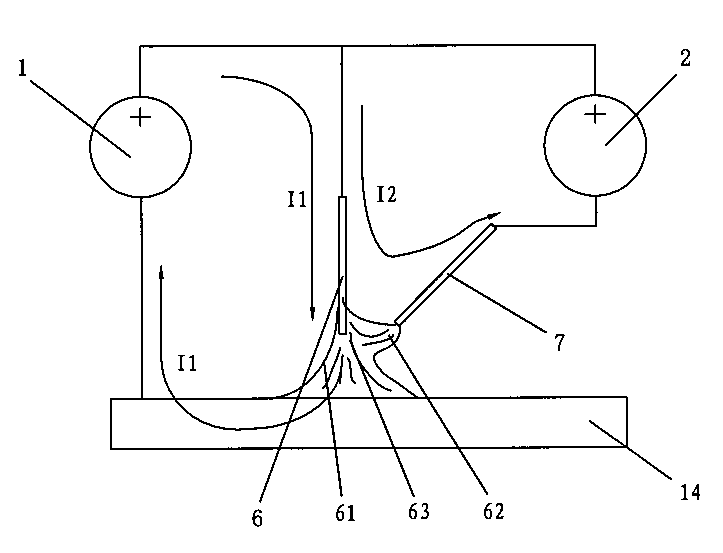

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

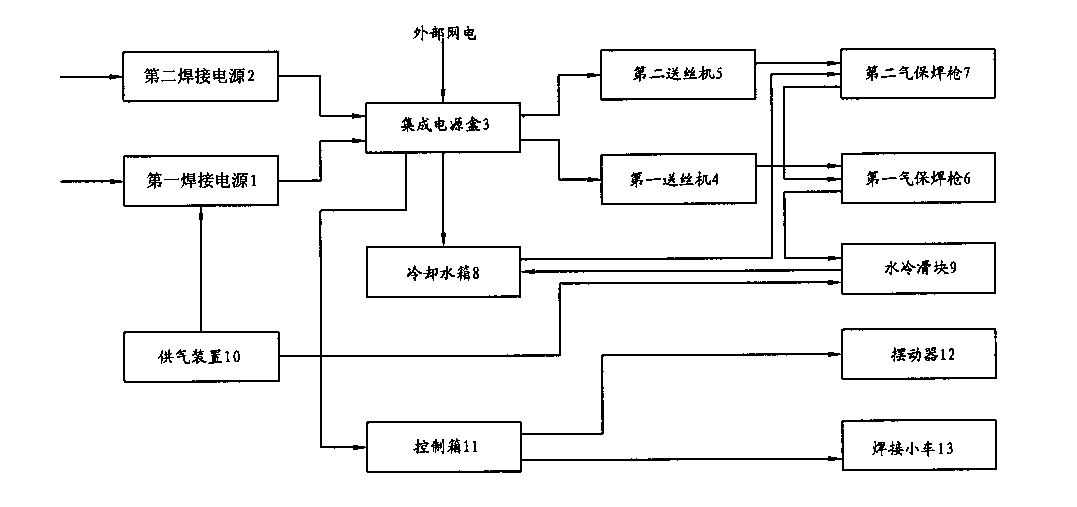

[0023] Please refer to the accompanying drawings Figure 1-6 . In the figure, the first welding power source 1, the second welding power source 2, the integrated power supply box 3, the first wire feeder 4, the second wire feeder 5, the first gas shielded welding gun 6, the second gas shielded welding gun 7, and the cooling water tank 8 , Water-cooled slider 9, gas supply device 10, control box 11, oscillator 12, welding trolley 13, main arc 61, auxiliary arc 62, composite arc 63.

[0024] Such as figure 1 , 2 as shown in:

[0025] The present invention provides a double-wire vertical gas-electric vertical welding system with low welding heat input, which includes a first welding power source 1, a second welding power source 2, an integrated power supply box 3, a first wire feeder 4, and a second wire feeder Machine 5, first gas-shielde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com