Metal workpiece punching machine with positioning device

A technology for metal workpieces and positioning devices, applied in metal processing equipment, manufacturing tools, portable drilling rigs, etc., can solve the problems of lack of tools for processing small workpieces, large volume of machining tools, and inability to move conveniently. The effect of wide processing range and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

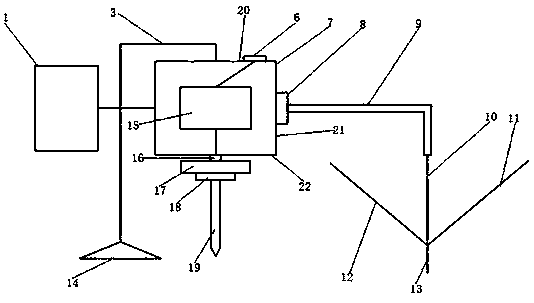

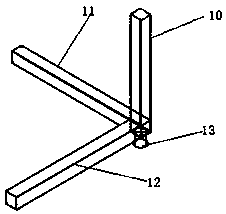

[0016] Such as figure 1 As shown, it mainly includes a coordinate value input device 1, a support frame 3, a charging interface 6, a motor box 7, a coordinate receiver 8, a coordinate bar 9, a Z-axis rod 10, an X-axis rod 11, a Y-axis rod 12, and a positioning base point 13. Support base 14, motor 15, lead rod 16, shaft chassis 17, drill bit mounting frame 18, drill bit 19, top surface 20, side surface 21 and bottom surface 22, motor box 7 includes top surface 20, side surface 21 and bottom surface 22. The coordinate value input device 1 is electrically connected to the motor box 7. One end of the support frame 3 is installed at the center of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com