Automatic numerical control welding device

A welding device and automatic technology, applied in welding equipment, welding accessories, arc welding equipment and other directions, can solve the problem that the welding speed cannot be accurately controlled, the amplitude of the welding rod swing, the welding speed and welding arc length cannot be accurately controlled, and the manual electrode arc welding Welding production efficiency is low and other problems, to achieve the effect of eliminating adverse effects, compact structure, protection and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

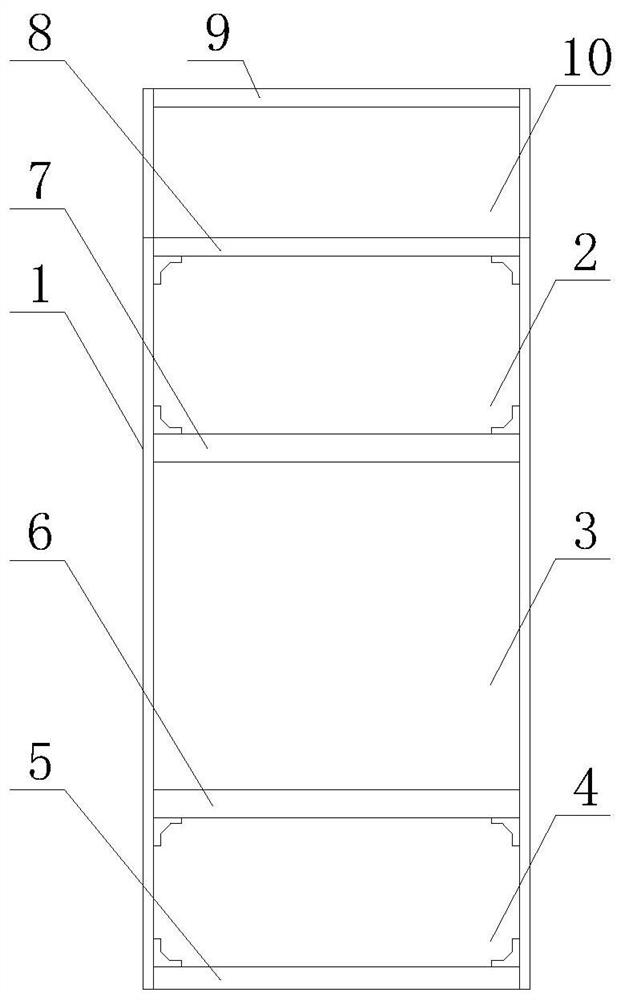

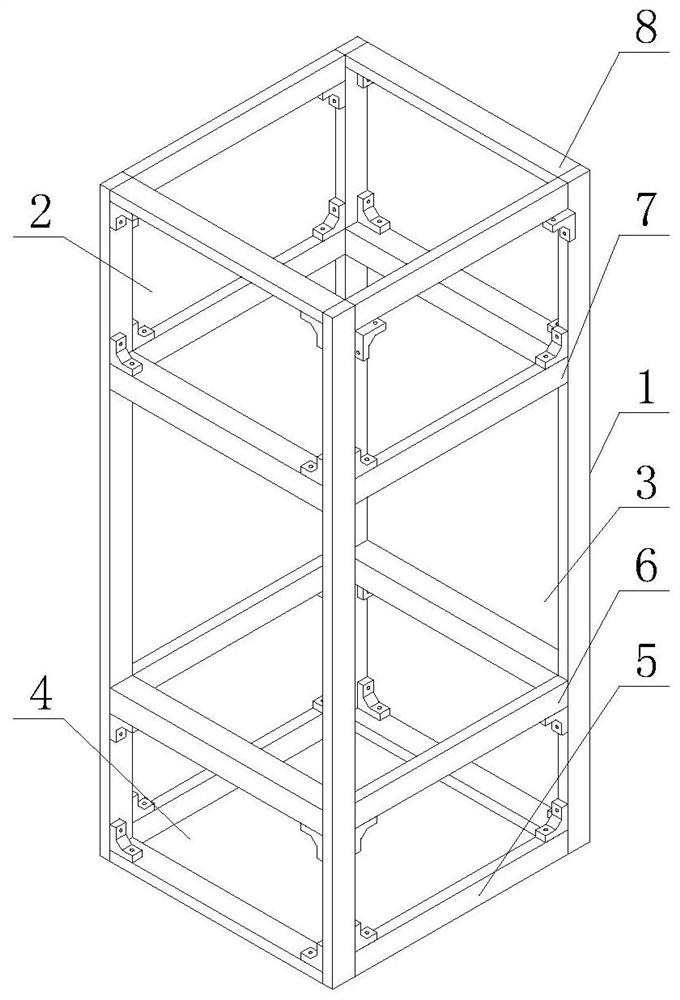

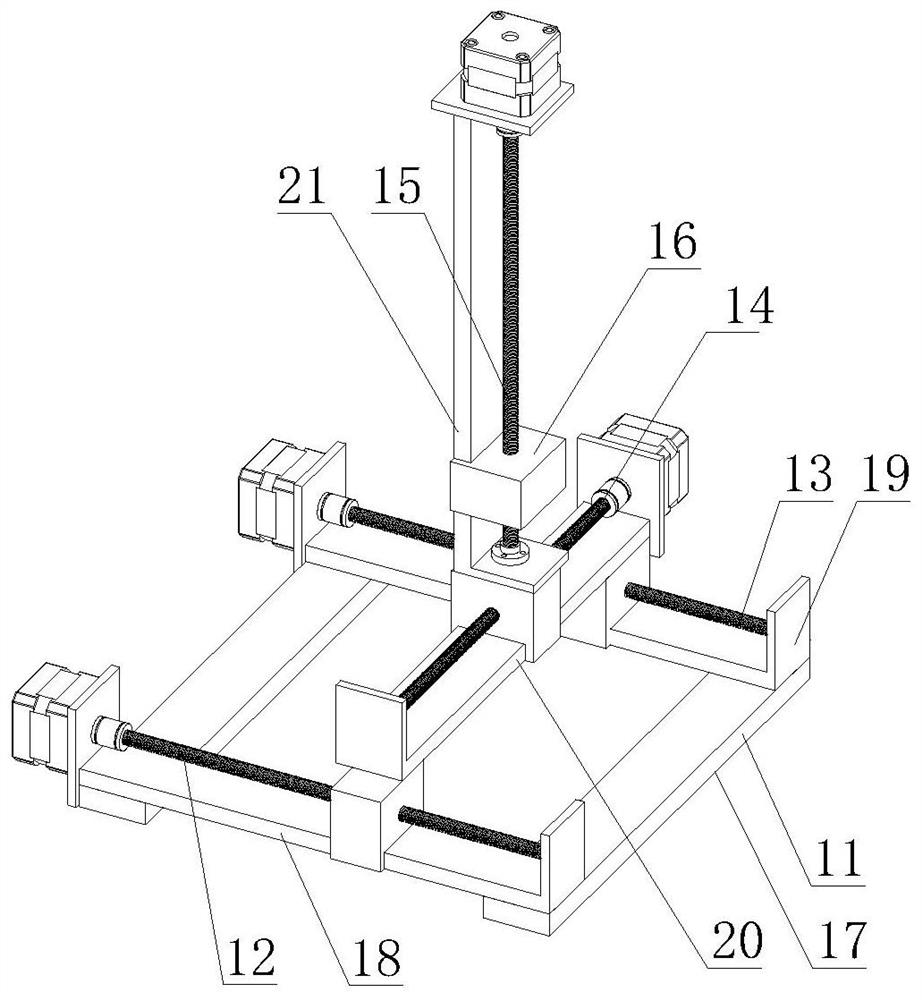

[0026] A kind of automatic numerical control welding device of the present invention, such as Figure 1-6 As shown, it includes a box body 1, and a frame body located inside the box body 1, the frame body includes a first frame 5, a second frame 6, a third frame 7, and a fourth frame 8; the first frame 5 , the second frame 6, the third frame 7, and the fourth frame 8 are vertically installed inside the box body 1 from bottom to top, and the first frame 5, the second frame 6, the third frame 7, and the fourth frame 8 pass through Four longitudinal columns are fixedly supported; the first frame 5, the second frame 6, the third frame 7, and the fourth frame 8 divide the interior of the box body 1 into three working areas, which are respectively the area to be welded 4 and the slide area 3. The fan filter area 2; the area to be welded 4, the sliding table area 3, and the fan filtering area 2 are connected; the sliding table part 17 is installed in the sliding table area 3; the sli...

Embodiment 2

[0040] A kind of automatic numerical control welding device of the present invention, such as Figure 1-6 As shown, the structure is the same as in Example 1; the dimensions are 504mm×514mm×1180mm. This device adopts CNC micro-numerical control four-axis servo / stepper motor controller, FFU fan filter and high-efficiency air purification filter; high-precision flat-shaped laser light red laser is used to align the weld; the supplementary lighting system selects a switch , external probe-type light control module, 24V LED spotlight and 24V DC power supply; select the DC 24V14.5A DC power supply that matches the rated voltage of the CNC micro-numerical control motion control system and the stepper motor controller as the power supply; select 16 subdivided 3200 pulses / revolutions two-phase stepper motor driver; the Y-axis slide 18, C-axis slide 19, X-axis slide 20, and Z-axis slide 21 are respectively equipped with mechanical touch limiters switch;

[0041] During the welding pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com