Mixed graphene oxide nanofiltration membrane and preparation method and application thereof

A graphene, nanofiltration membrane technology, applied in chemical instruments and methods, membranes, membrane technology and other directions, can solve the problems of low desalination efficiency, weak long-term stability, etc., to improve salt interception efficiency, strong mechanical stability, reduce The effect of layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

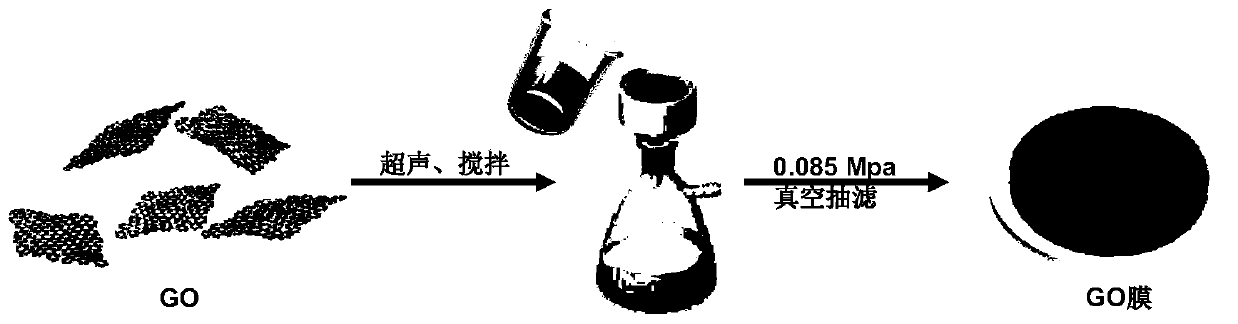

[0061] A small size graphene oxide nanofiltration membrane:

[0062] Include the following steps:

[0063] S1: Disperse and centrifuge graphene oxide first, then take the supernatant for drying and quantification to obtain small-sized graphene oxide. The specific preparation steps are:

[0064] S11: After dispersing the graphene oxide, centrifuge at 400rpm for 3 minutes, and then take the supernatant;

[0065] S12: continue to centrifuge the supernatant obtained in S11 at 12000 rpm for 3 minutes, and take the supernatant;

[0066] S13: continue to centrifuge the supernatant obtained in S12 at 12000 rpm for 3 minutes, take the supernatant, and then dry and quantify it to obtain small-sized graphene oxide;

[0067] S2: configuring the obtained small-sized graphene oxide into a small-sized graphene oxide dispersion with pure water;

[0068] S3: The concentration of the small-sized graphene oxide dispersion is 0.05 mg / mL, and stirring and ultrasonic dispersion are carried out f...

Embodiment 2

[0070] A large-scale graphene oxide nanofiltration membrane:

[0071] Include the following steps:

[0072] S1: Disperse and centrifuge the graphene oxide first, then take the precipitate at the bottom for drying and quantification to obtain large-size graphene oxide;

[0073] Concrete preparation steps are:

[0074] S11: After dispersing the graphene oxide, centrifuge at 400 rpm for 3 minutes, and collect the precipitate after standing still;

[0075] S12: After dispersing the precipitate obtained in S11, centrifuge at 400 rpm for 3 minutes, and take the precipitate after standing still;

[0076] S13: After dispersing the precipitate obtained in S12, centrifuge at 400 rpm for 3 minutes, take the precipitate after standing still, dry and quantify the precipitate to obtain large-sized graphene oxide;

[0077] S2: The large-size graphene oxide is prepared into a large-size graphene oxide dispersion with pure water;

[0078] S3: The concentration of the large-size graphene ox...

Embodiment 3

[0080] A hybrid graphene oxide nanofiltration membrane:

[0081] Include the following steps:

[0082] S1: Disperse and centrifuge the graphene oxide first, then take the supernatant to dry and quantify to obtain small-sized graphene oxide; take the bottom precipitate to dry and quantify to obtain large-sized graphene oxide;

[0083] Specific steps for preparing large-scale graphene oxide:

[0084] S11: After dispersing the graphene oxide, centrifuge at 400 rpm for 3 minutes, and collect the precipitate after standing still;

[0085] S12: After dispersing the precipitate obtained in S11, centrifuge at 400 rpm for 3 minutes, and take the precipitate after standing still;

[0086] S13: After dispersing the precipitate obtained in S12, centrifuge at 400 rpm for 3 minutes, take the precipitate after standing still, dry and quantify the precipitate to obtain large-sized graphene oxide.

[0087] Specific steps for preparing small-sized graphene oxide:

[0088] S14: Collect the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com