Anti-mud agent and preparation method thereof

A technology of anti-mud agent and emulsifier, which is applied in the field of anti-mud agent and its preparation, which can solve the problems of late influence on concrete, affect concrete strength, and large amount of anti-mud agent, so as to improve hydrophilicity and reduce cost price , the effect of reducing the amount of adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

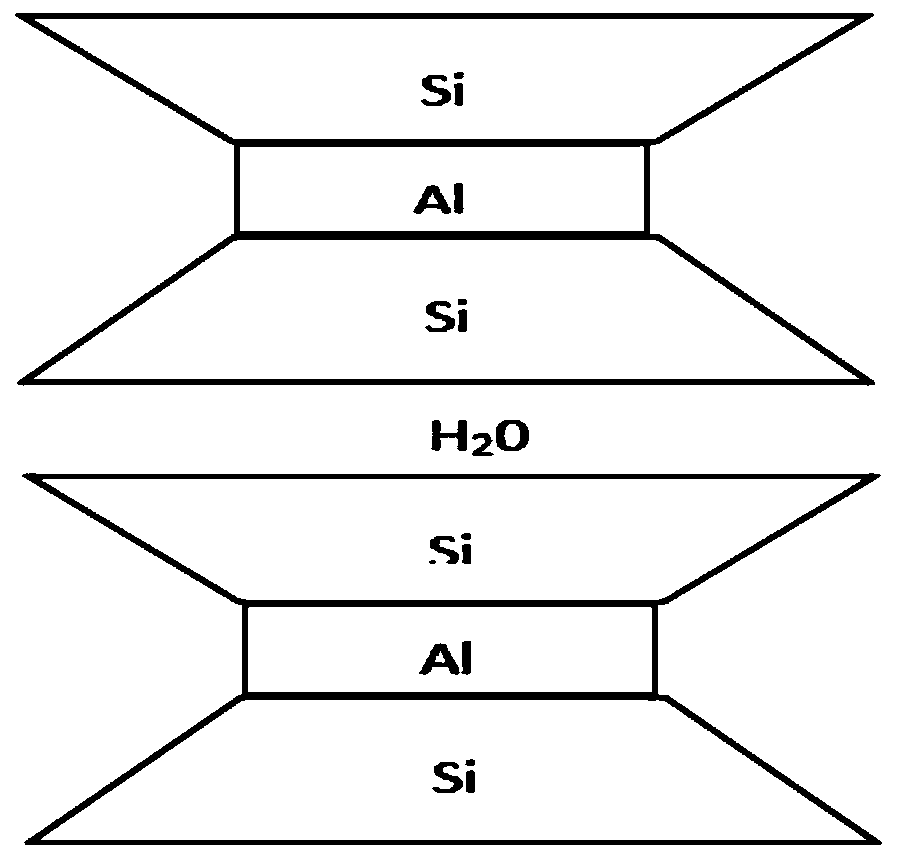

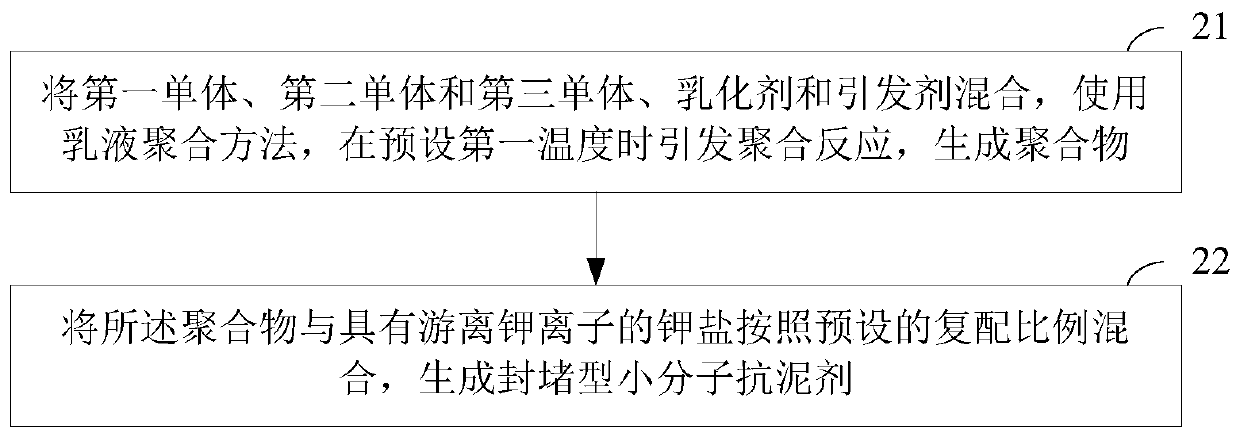

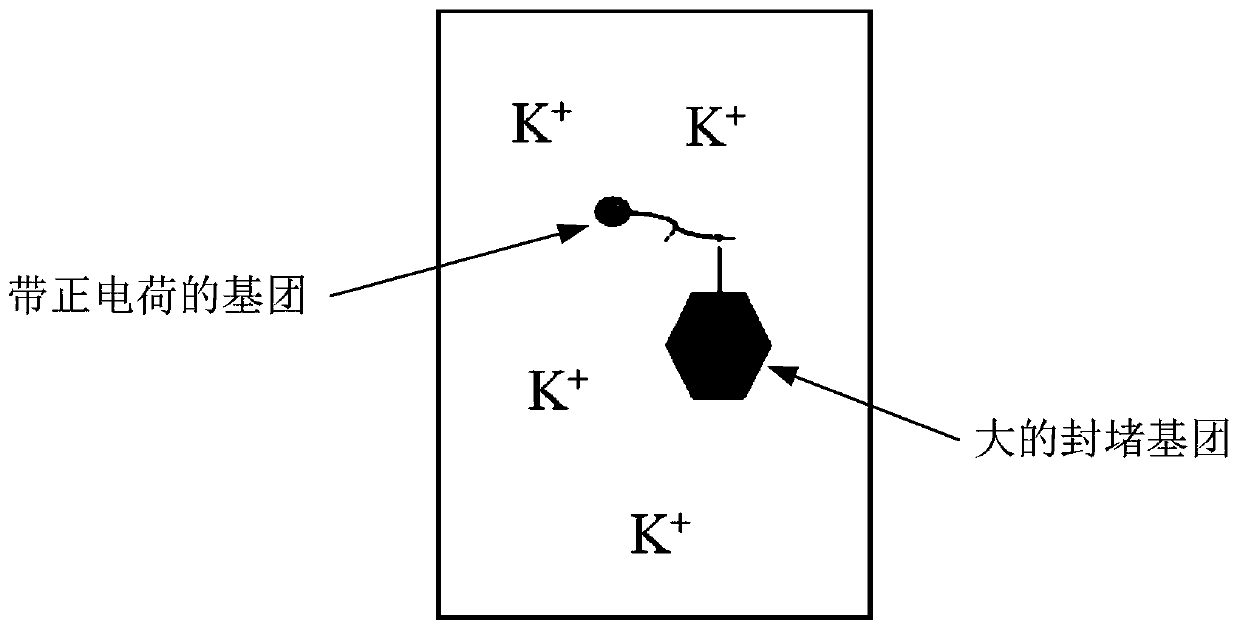

[0032] In the technical solution of the present invention, a plugging-type small molecule anti-mud agent is proposed, and the raw materials of the plug-type small-molecule anti-mud agent include: polymer and potassium salt with free potassium ions;

[0033] The weight proportion of described polymer and potassium salt is 1:1;

[0034] Wherein, the polymer is made of the following raw materials in parts by weight: 17% of water-soluble cationic polymerizable monomers, 17% of water-soluble polymerizable small monomers, 17% of polymerizable monomers with large groups, 2% of emulsifiers, initiator agent 0.1% and water 46.9%.

[0035] In addition, as an example, in a preferred specific embodiment of the present invention, the water-soluble cationic po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com