Lithium ion battery containing graphene/cellulose composite material, and preparation method thereof

A lithium-ion battery, composite material layer technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of battery cycle performance impact, increase battery weight, etc., achieve high cycle capacity and cycle stability, improve capacity, The effect of suppressing the growth of dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

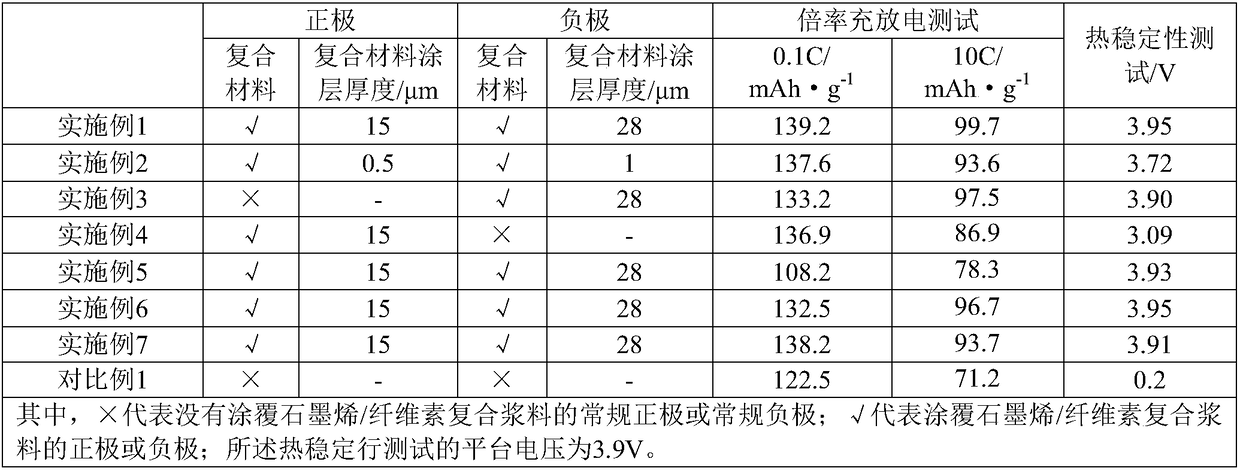

Embodiment 1

[0078] Step 1) fully mix natural flake graphite 60g and ethyl cellulose 100g, and ball mill 5h at room temperature to obtain composite graphene cellulose material powder;

[0079] Step 2) Sodium dodecylbenzene sulfonate 25g is dissolved in 460mL water, then the graphene cellulose material 160g obtained in step 1) is dissolved in the above-mentioned water, fully stirred, and the graphene / cellulose composite slurry is obtained;

[0080] Step 3) Preparation of positive electrode of battery

[0081] Preparation of the positive electrode sheet: 85 parts of the positive active material lithium cobaltate, 5 parts of acetylene black, 5 parts of conductive graphite, and 5 parts of PVDF are fully mixed with N-methylpyrrolidone to obtain the positive electrode slurry, which is evenly coated on the surface of the aluminum foil current collector to complete Preparation of positive electrode sheet;

[0082] Coating the graphene / cellulose composite slurry obtained in step 2) on the surface ...

Embodiment 2

[0090] Repeat embodiment 1, difference is:

[0091] Step 1) fully mix natural flake graphite 30g and ethyl cellulose 100g, and ball mill 5h at room temperature to obtain composite graphene cellulose material powder;

[0092] Step 2) dissolving 15g of methyl amyl alcohol in 1500mL water, then dissolving 145g of the graphene cellulose material obtained in step 1) in the above-mentioned water, fully stirring to obtain a graphene / cellulose composite slurry;

[0093] In step 3), the thickness of the mixed slurry coating on the surface of the positive electrode is 0.5 μm;

[0094] In step 4), the thickness of the mixed slurry coating on the surface of the negative electrode is 1 μm;

Embodiment 3

[0096] Repeat embodiment 1, difference is:

[0097] Step 1) fully mix crystalline graphite 10g and ethyl cellulose 100g, and ball mill 5h at room temperature to obtain composite graphene cellulose material powder;

[0098] Step 2) Sodium lauryl sulfate 0.3g is dissolved in 3700mL water, then the graphene cellulose material 11g obtained in step 1) is dissolved in the above-mentioned water, fully stirred, and the graphene / cellulose composite slurry is obtained;

[0099] In step 3), the positive electrode pole piece is not coated with the mixed slurry.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com