Graphene substrate and thin film lithium battery with same

A graphene and lithium battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of thin-film lithium batteries such as weak bonding, large interface resistance changes, and electrode material shedding, and achieve superior thermal stability, Low interfacial internal resistance and improved energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

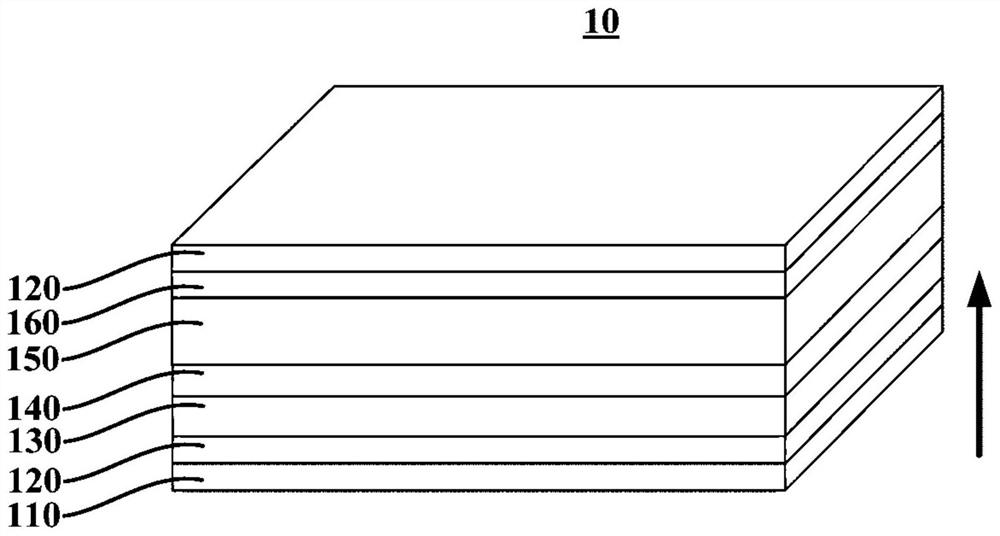

[0042] Utilize the graphene substrate 120 prepared by the above method, adopt the magnetron sputtering coating technology, deposit the graphene-based thin-film lithium battery 10 of a single section: Coat the graphene substrate 120 that is 6 μ m in thickness on the copper foil surface of 1 square meter, on graphite The negative electrode film 130 , the solid electrolyte film 140 , the positive electrode film 150 and the graphene collector film 120 are sequentially deposited on the graphene substrate 120 . Wherein, the deposited negative electrode film 130 has a thickness of 4.5 μm, the deposited solid electrolyte film 140 has a thickness of 1.5 μm, and the deposited positive electrode film 150 has a thickness of 15 μm. The thickness of the graphene collector thin film 120 is 6 μm. The obtained battery has a capacity of 12240 (mA·h) after formation.

Embodiment 2

[0044] Using the graphene substrate 120 prepared by the above method, two graphene-based thin-film lithium batteries 10 connected in series are deposited by magnetron sputtering coating technology: a graphene substrate 120 with a thickness of 7 μm is coated on the surface of copper foil of 1 square meter, And sequentially deposit negative electrode film 130, solid electrolyte film 140, positive electrode film 150, graphene collector film 120, negative electrode film 130, solid electrolyte film 140, positive electrode film 150 and graphene collector film 120 on the graphene substrate 120. Among them, the thickness of the negative electrode film 130 of each deposited battery is 5.5 μm, the thickness of the solid electrolyte film 140 of each battery is 2.0 μm, the thickness of the positive electrode film 150 of each battery is 18.5 μm, and the graphene collector film of each battery The thickness of 120 is 7 μm. The obtained battery has a capacity of 15096 (mA·h) after formation....

Embodiment 3

[0046] Utilize the graphene substrate 120 prepared by the above method, adopt magnetron sputtering coating technology, deposit two graphene-based thin-film lithium batteries 10 connected in parallel: coat a graphene substrate 120 with a thickness of 7 μm on the surface of copper foil of 1 square meter, And sequentially deposit negative electrode film 130, solid electrolyte film 140, positive electrode film 150, graphene collector film 120, positive electrode film 150, solid electrolyte film 140, negative electrode film 130 and graphene collector film 120 on the graphene substrate 120. Among them, the thickness of the negative electrode film 130 of each deposited battery is 6.5 μm, the thickness of the solid electrolyte film 140 of each deposited battery is 2.5 μm, the thickness of the positive electrode film 150 of each deposited battery is 22 μm, and the thickness of each deposited battery is 22 μm. The thickness of the graphene collector thin film 120 is 7 μm. The resulting ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com