A kind of preparation method and application of nickel cloth current collector

A current collector and nickel cloth technology, which is applied in the field of flexible current collectors, can solve the problems of unfavorable commercial production of batteries, high cost, and complicated operation, and achieve the effects of favorable maintenance, easy operation, and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

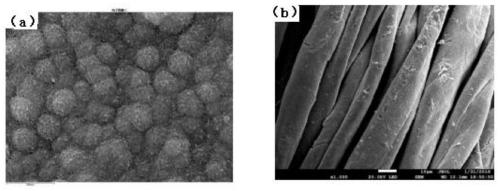

[0041] The preparation method of a nickel cloth current collector in this embodiment is to use gauze as the base, and then carry out roughening, sensitization and activation, reduction, electroless nickel plating and post-treatment processes on the base, so that the metal conductive nickel layer is evenly coated On the fibers of the base, the method specifically comprises the following steps:

[0042] (1) Substrate roughening: at 70°C, soak the substrate material in the roughening solution for 30 minutes, and then wash it with deionized water to obtain the roughened substrate material, wherein the roughening solution is sodium hydroxide aqueous solution, the concentration of sodium hydroxide in the roughened solution is 200g / L;

[0043] (2) Sensitization and activation: at room temperature, put the roughened base material described in step (1) into the sensitization activation solution and soak for 5 minutes, then wash with deionized water to obtain the base material after sen...

Embodiment 2

[0059] The preparation method of a nickel cloth current collector in this embodiment is to use gauze as the base, and then carry out roughening, sensitization and activation, reduction, electroless nickel plating and post-treatment processes on the base, so that the metal conductive nickel layer is evenly coated on the fibers of the base. The present embodiment adopts the same process steps and process parameters as in Example 1, the only difference is that the mixed solution in step (5) is composed of cobalt chloride, hexamethylenetetramine (HMT) and deionized water, and the chlorine Cobalt chloride is 6 mmol, hexamethylenetetramine is 10 mmol, and deionized water is 60 ml.

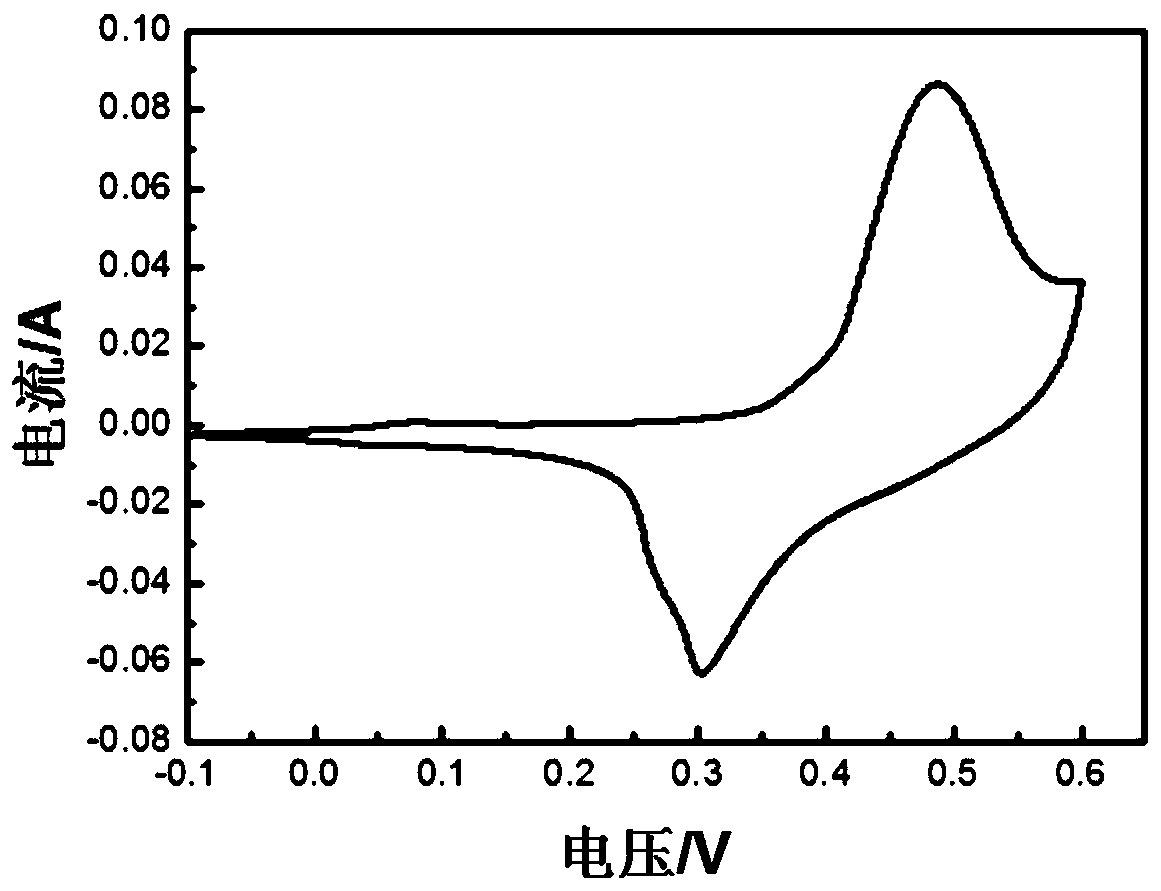

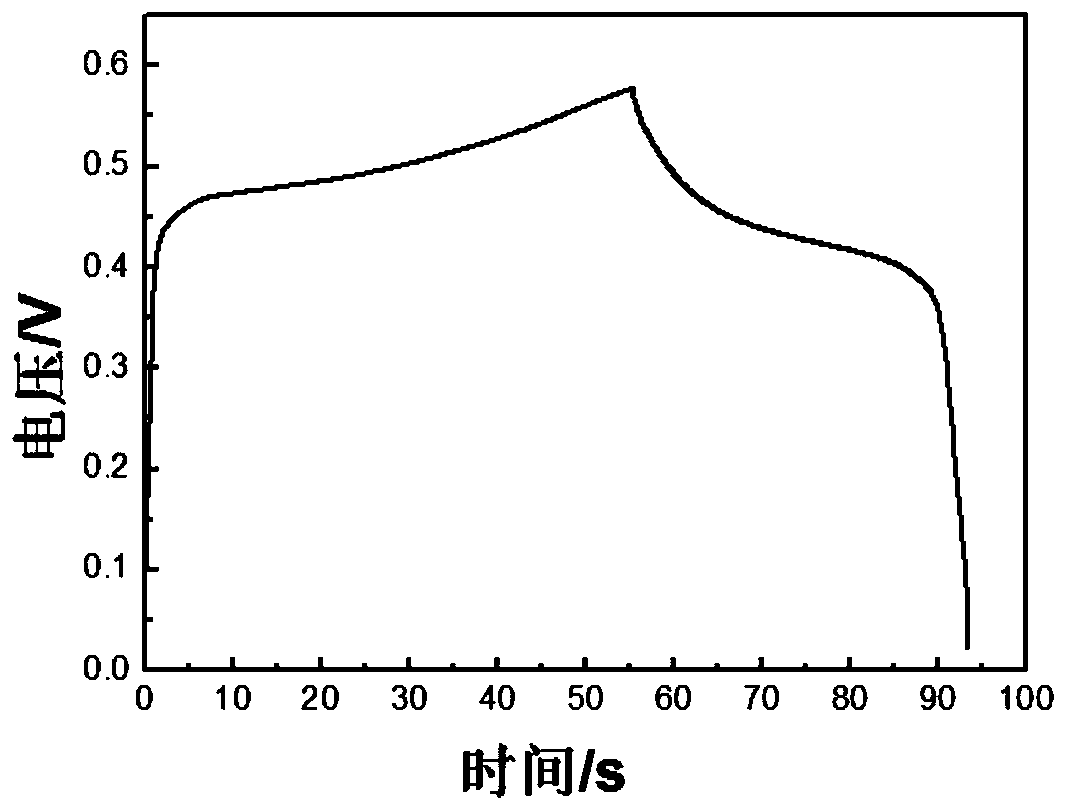

[0060] The nickel cloth prepared in this embodiment was subjected to a scanning electron microscope (SEM) test, and a layer of uniform metal nickel was plated on the surface of the gauze substrate, which can effectively improve the conductivity of the battery, and it was tested for electrochemical perfor...

Embodiment 3

[0062] The preparation method of a nickel cloth current collector in this embodiment is to use gauze as the base, and then carry out roughening, sensitization and activation, reduction, electroless nickel plating and post-treatment processes on the base, so that the metal conductive nickel layer is evenly coated on the fibers of the base. This embodiment adopts the same process steps and process parameters as in Example 1, the only difference is that the mixed solution in the step (5) of this embodiment is composed of nickel chloride hexahydrate, hexamethylenetetramine (HMT) and deionized Water composition, described nickel chloride hexahydrate is 6mmol, hexamethylenetetramine is 10mmol, and deionized water is 60ml.

[0063] The nickel cloth prepared in this embodiment was subjected to a scanning electron microscope (SEM) test, and a layer of uniform metal nickel was plated on the surface of the gauze substrate, which can effectively improve the conductivity of the battery, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com