Composite positive electrode for solid-state battery and preparation method thereof

A composite positive electrode and solid-state battery technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve the problems of low capacity, poor capacity retention rate, poor rate performance and cycle performance of solid-state batteries, and reduce ion transmission. Distance, reduce interface internal resistance, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

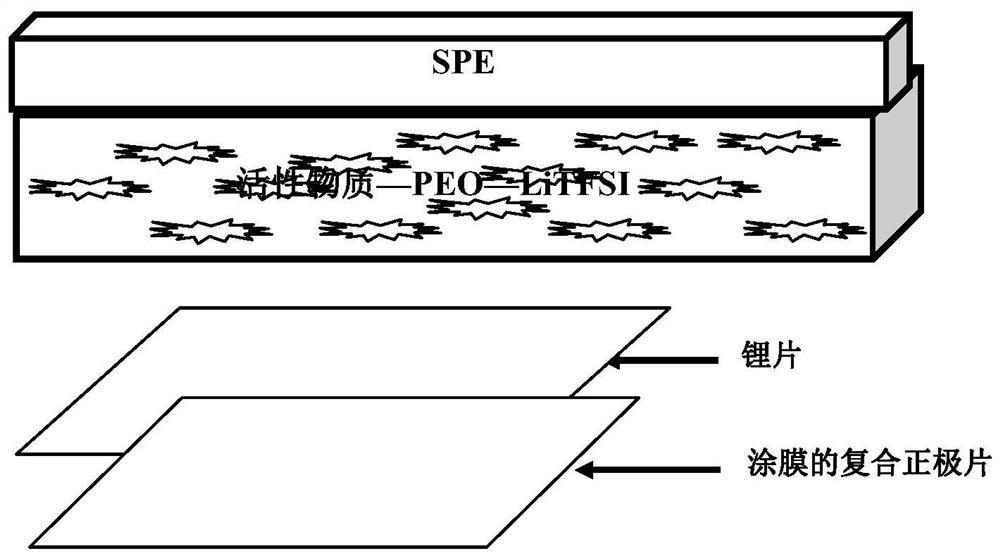

[0039] Embodiment 1, a method for manufacturing a high-capacity solid-state battery

[0040] (1) Preparation of positive electrode slurry

[0041] Weigh 4.0g of positive electrode material LFP, 0.5g of conductive carbon black, and 0.5g of PVDF, pour them into the agate grinder, and grind for 20 minutes until uniform; weigh 15g of NMP into a weighing bottle, and slowly add the completely ground powder with a key, Add while stirring, after complete addition, adjust the magnetic stirring speed to 500rpm / min, stir for 6h, and obtain positive electrode slurry.

[0042] (2) Preparation of solid electrolyte slurry

[0043] Weigh 2.3g of polymer PEO, 0.7g of lithium salt LiTFSI, slowly add to the solvent acetonitrile, the amount of acetonitrile is 13.8g, magnetically stir at 500rpm / min for 5h to obtain a solid electrolyte slurry. (3) Preparation of composite positive electrode sheet

[0044] Weigh 0.35g of the solid electrolyte slurry prepared in step (2) and add it to the positive...

Embodiment 2

[0049] Embodiment 2, a method for manufacturing a high-capacity solid-state battery

[0050] (1) Preparation of positive electrode slurry

[0051] Weigh 4.5g of positive electrode material LFP, 0.25g of conductive carbon black, and 0.25g of PVDF, pour them into the agate grinder, and grind for 20 minutes until uniform; weigh 15g of NMP into a weighing bottle, and slowly add the completely ground powder with a key, Add while stirring, after complete addition, adjust the magnetic stirring speed to 500rpm / min, stir for 6h, and obtain positive electrode slurry.

[0052] (2) Preparation of solid electrolyte slurry

[0053] Weigh 2.3g of polymer PEO, 0.7g of lithium salt LiTFSI, slowly add to the solvent acetonitrile, the amount of acetonitrile is 13.8g, magnetically stir at 500rpm / min for 5h to obtain a solid electrolyte slurry.

[0054] (3) Preparation of composite positive electrode sheet

[0055] Weigh 0.35g of the solid electrolyte slurry prepared in step (2) and add it to t...

Embodiment 3

[0060] Embodiment 3, a method for manufacturing a high-capacity solid-state battery:

[0061] (1) Preparation of positive electrode slurry

[0062] Weigh 4.75g of positive electrode material LFP, 0.125g of conductive carbon black, and 0.125g of PVDF, pour them into the agate grinder, and grind for 20 minutes until uniform; weigh 15g of NMP into a weighing bottle, and slowly add the completely ground powder with a key, Add while stirring, after complete addition, adjust the magnetic stirring speed to 500rpm / min, stir for 6h, and obtain positive electrode slurry.

[0063] (2) Preparation of solid electrolyte slurry

[0064] Weigh 2.3g of polymer PEO, 0.7g of lithium salt LiTFSI, slowly add to the solvent acetonitrile, the amount of acetonitrile is 13.8g, magnetically stir at 500rpm / min for 5h to obtain a solid electrolyte slurry.

[0065] (3) Preparation of composite positive electrode sheet

[0066] Weigh 0.35g of the solid electrolyte slurry prepared in step (2) and add it ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com