Nitrogen and sulfur co-doped hierarchical porous carbon composite material, and preparation method and application thereof

A composite material and co-doping technology, which is applied in the field of nitrogen and sulfur co-doped multi-level porous carbon composite materials and its preparation, can solve the problem that the improvement of electrochemical performance is not very significant, the pore size distribution of carbon materials is single, and the waste water and gas environment Pollution and other issues, achieve excellent electrochemical performance, avoid large-area stacking and agglomeration, and reduce the generation of waste gas and wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

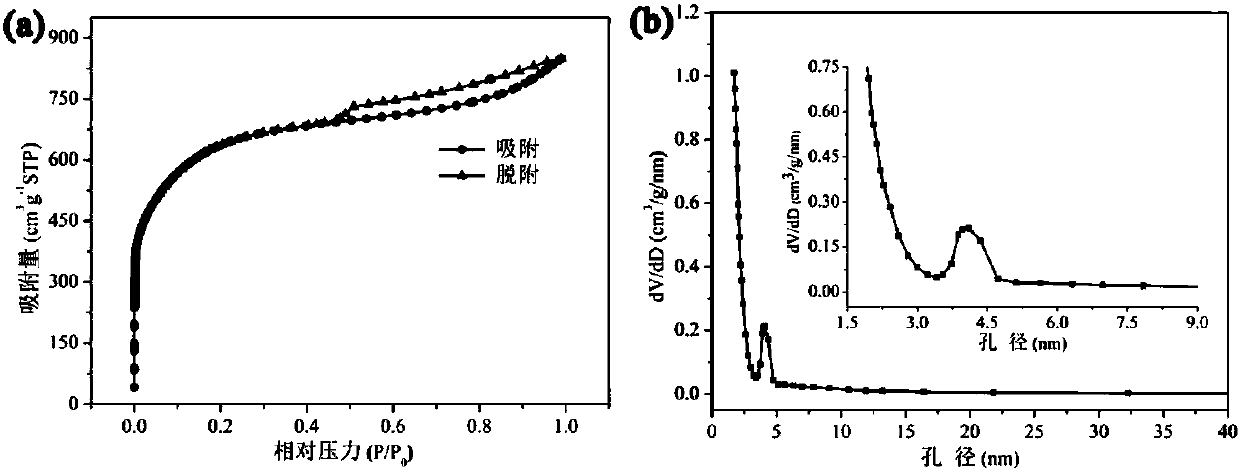

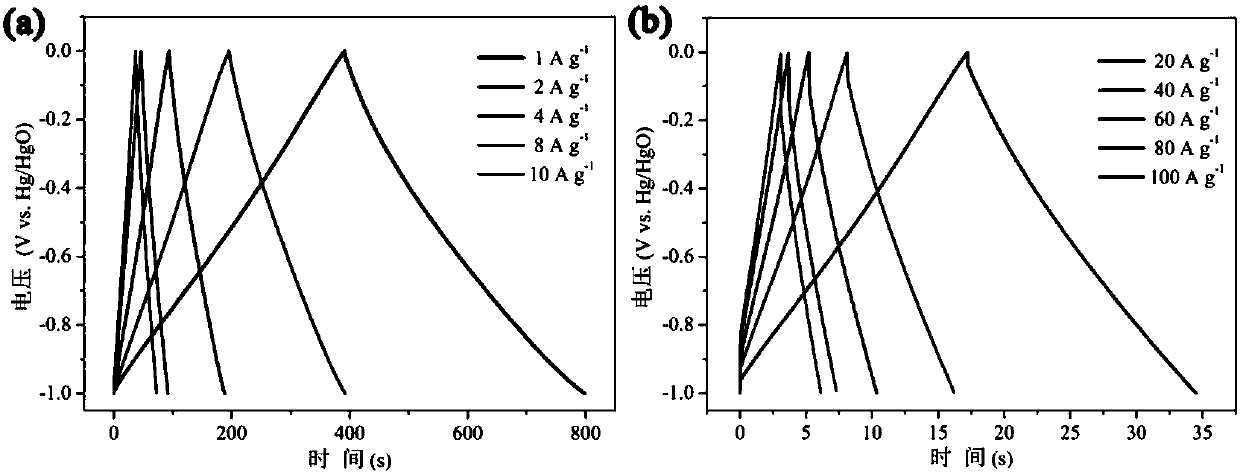

[0043] [Example 1] Preparation of nitrogen and sulfur co-doped multi-level porous carbon composite material and its electrochemical performance test as a supercapacitor electrode material.

[0044] Dissolve 0.5g chitosan in 20ml acetic acid solution (0.5vol.%), fully stir at 45°C to obtain light yellow clear solution A, wherein the concentration of chitosan is 0.025g / ml; then add 0.1g amino Thiourea and 5ml 10wt.% Na 2 CO 3 aqueous solution, fully stirred to obtain a clear mixed solution B; another 2 mg of graphene oxide powder was placed in 20 ml of deionized water, and ultrasonically used for 2 hours to obtain a graphene oxide dispersion C, wherein the concentration of graphene oxide was 0.1 mg / ml; the solution B Mix and stir evenly with dispersion C at 45°C for 2h, add 0.4ml of glutaraldehyde solution (25wt.%) to the mixed solution until it is completely cross-linked to obtain a transparent hydrogel, and freeze-dry it The airgel precursor with a multi-level pore structure...

Embodiment 2

[0046] Example 2: Preparation of nitrogen and sulfur co-doped hierarchical porous carbon composite material and its electrochemical performance test as supercapacitor electrode material.

[0047] Dissolve 1.0g of gelatin in 20ml of deionized water, stir well at 60°C to obtain light yellow clear solution A, in which the concentration of gelatin is 0.05g / ml; then add 0.5g of ammonium sulfate and 5ml of 5wt.% KHCO in sequence 3 aqueous solution, fully stirred to obtain a clear mixed solution B; another 4 mg of graphene oxide powder was placed in 20 ml of deionized water, and ultrasonically applied for 2 hours to obtain a graphene oxide dispersion C, wherein the concentration of graphene oxide was 0.2 mg / ml; the solution B Mix and stir evenly with dispersion C at 60°C for 2 hours, place it at 4°C until it becomes gelatinous, and freeze-dry it to obtain an airgel precursor with a multi-level pore structure, and then transfer the above precursor to a tube In the furnace, the tempera...

Embodiment 3

[0048] Example 3: Preparation of nitrogen and sulfur co-doped hierarchical porous carbon composite material and its electrochemical performance test as supercapacitor electrode material.

[0049] Dissolve 1.0g of agarose in 20ml of deionized water and stir fully at 95°C to obtain a clear solution A, in which the concentration of agarose is 0.05g / ml; then add 1.0g of thiourea and 8ml of 20wt.% KOH aqueous solution in sequence, fully Stir to obtain a clear mixed solution B; take another 10 mg of graphene oxide powder in 20 ml of deionized water, and ultrasonically 2 hours to obtain a graphene oxide dispersion C, wherein the concentration of graphene oxide is 0.5 mg / ml; the solution B and the dispersion C was uniformly mixed and stirred at 95°C for 2h, placed at 4°C until gelatinous, and then freeze-dried to obtain an airgel precursor with a multi-level pore structure, and then moved the above precursor to a tube furnace , in a nitrogen atmosphere at a heating rate of 5°C / min to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com