Composite current collector and lithium ion battery

A lithium-ion battery and current collector technology, applied in battery electrodes, secondary batteries, electrode carriers/current collectors, etc., can solve the problems of single structure, heavy weight, and high cost of current collectors, so as to improve mass energy density and reduce production cost, and the effect of improving the cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0051] As a preferred embodiment of the present invention, the non-metallic material is polyester (PET), polypropylene (PP), polyamide (PA), polyimide (PI), polyethylene (PE), polyethylene oxide ( PEO), polyvinyl chloride (PVC), acrylonitrile-butadiene-styrene copolymer (ABS), polycarbonate (PC), polymethyl methacrylate (PMMA), polytetrafluoroethylene (PTFE) , polyvinyl alcohol (PVA), non-woven fabric, polyester, carbon fiber, carbon tube, graphene, etc., any one or more composites.

[0052] As a preferred embodiment of the present invention, several holes 20 are provided on the carrier layer 2, and the holes 20 make the carrier layer 2 have a porosity of 3%-95%. Its advantages are: setting holes on the carrier layer can not only further reduce the weight of the carrier layer and the composite current collector, but also improve the mass energy density of the battery, and the holes are easy to form a conductive structure to facilitate the flow of ions, thereby ensuring the com...

Embodiment 1

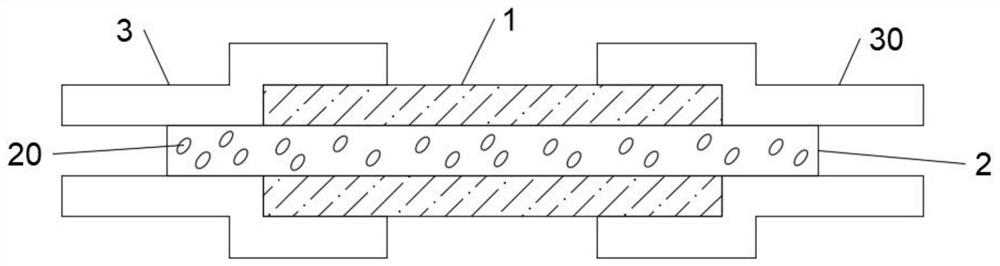

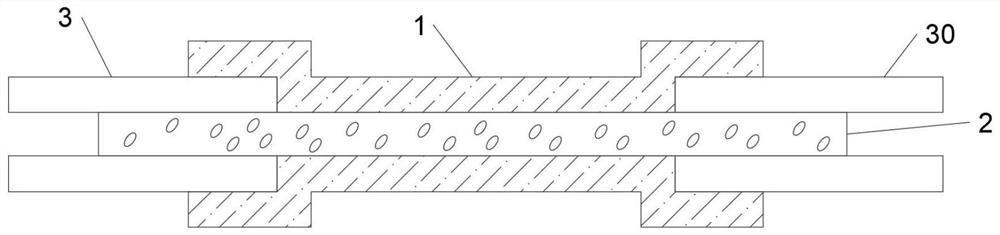

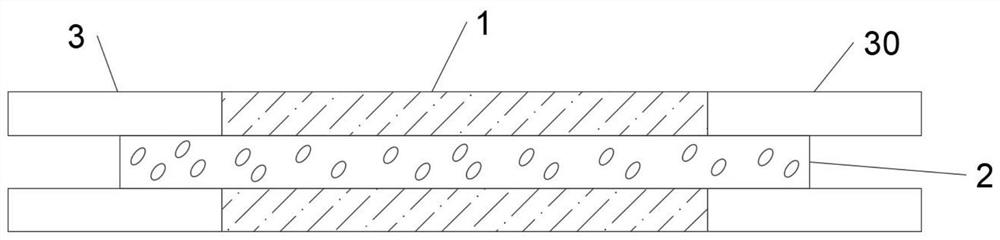

[0057] Such as figure 1 As shown, the composite current collector of the present invention includes two conductive layers 1 containing carbon materials, and a carrier layer 2 containing non-metallic materials. The carrier layer 2 provides a flowing carrier for the conductive layer 1 . The conductive layer 1 is connected to the carrier layer 2 , and the edges of the conductive layer 1 and the carrier layer 2 are spliced and fixed through the splicing and fixing layer 3 . Specifically, two conductive layers 1 sandwich the carrier layer 2 , the two conductive layers 1 are respectively connected to the top surface and the bottom surface of the carrier layer 2 , and the two conductive layers 1 are vertically symmetrical with respect to the carrier layer 2 . The carrier layer 2 provides a carrier for the two conductive layers 1 . Holes 20 are provided on the carrier layer 2 to facilitate the conduction of ions between the two conductive layers 1 .

[0058] In the first embodimen...

Embodiment 2

[0062] Such as Figure 4 as shown, Figure 4 It is a schematic diagram of the structure of the composite current collector of Embodiment 2 of the present invention; the composite current collector of the present invention includes a conductive layer 1 of carbon-containing material, and a carrier layer 2 containing non-metallic material, and the carrier layer 2 provides flow for the conductive layer 1 carrier. The conductive layer 1 is connected to the carrier layer 2 , and the edges of the conductive layer 1 and the carrier layer 2 are spliced and fixed through the splicing and fixing layer 3 .

[0063] The conductive layer 1 is a combination of several independent sub-conductive layers 10 . Several embedding holes are provided on the carrier layer 2, and several sub-conductive layers 10 are respectively inserted into the embedding holes. Several sub-conductive layers 10 are arranged parallel to each other and equidistant, and the top surfaces have the same height. The t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com