Natural gas type synthesis ammonia energy-saving and emission-reduction technology

A technology of energy saving and emission reduction, process technology, applied in the field of process industry, to achieve the effect of reducing energy consumption and emissions, reducing emissions and energy consumption, good controllability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Specific embodiments of the present invention will be described in detail below in conjunction with technical solutions and accompanying drawings.

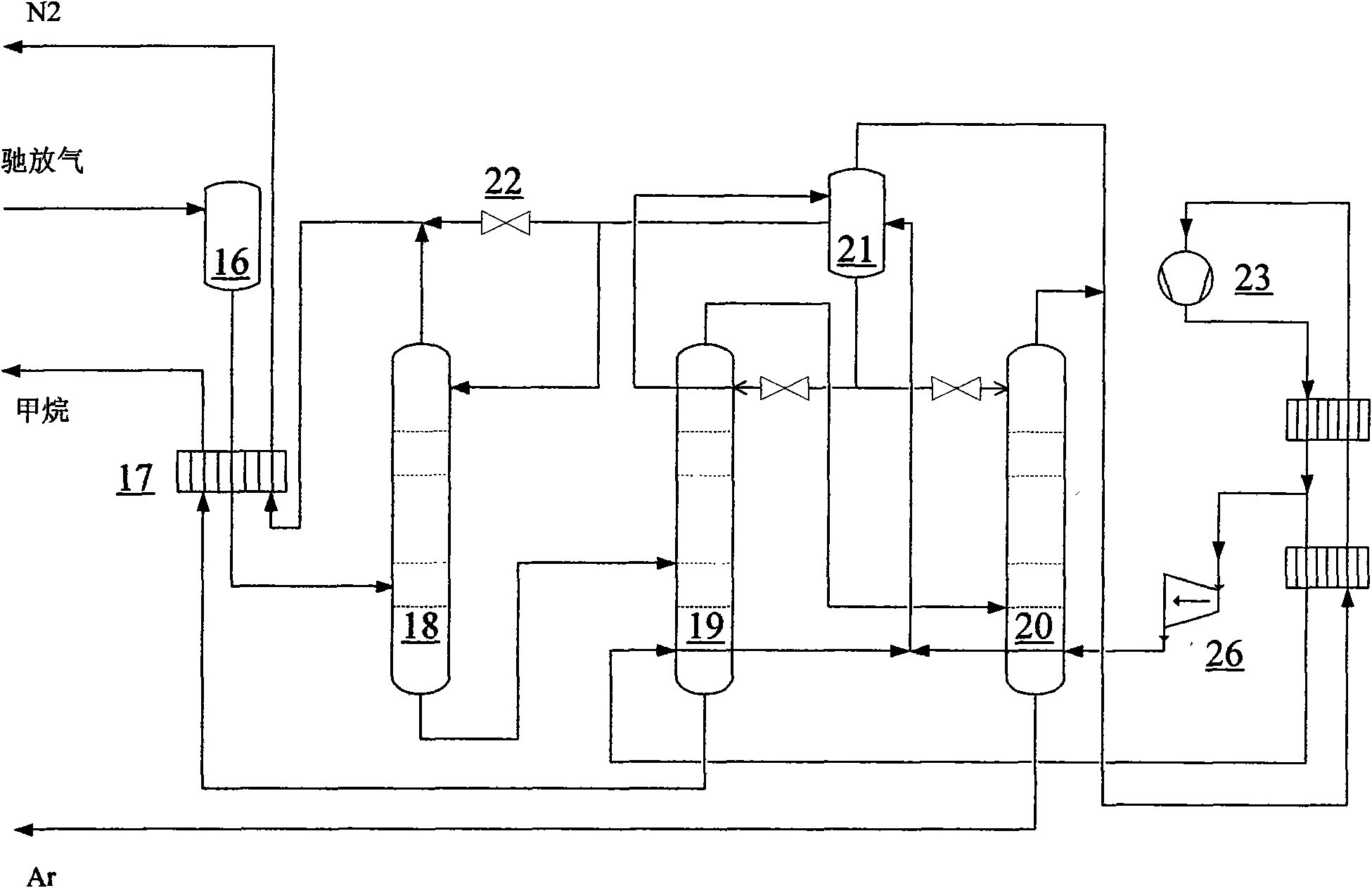

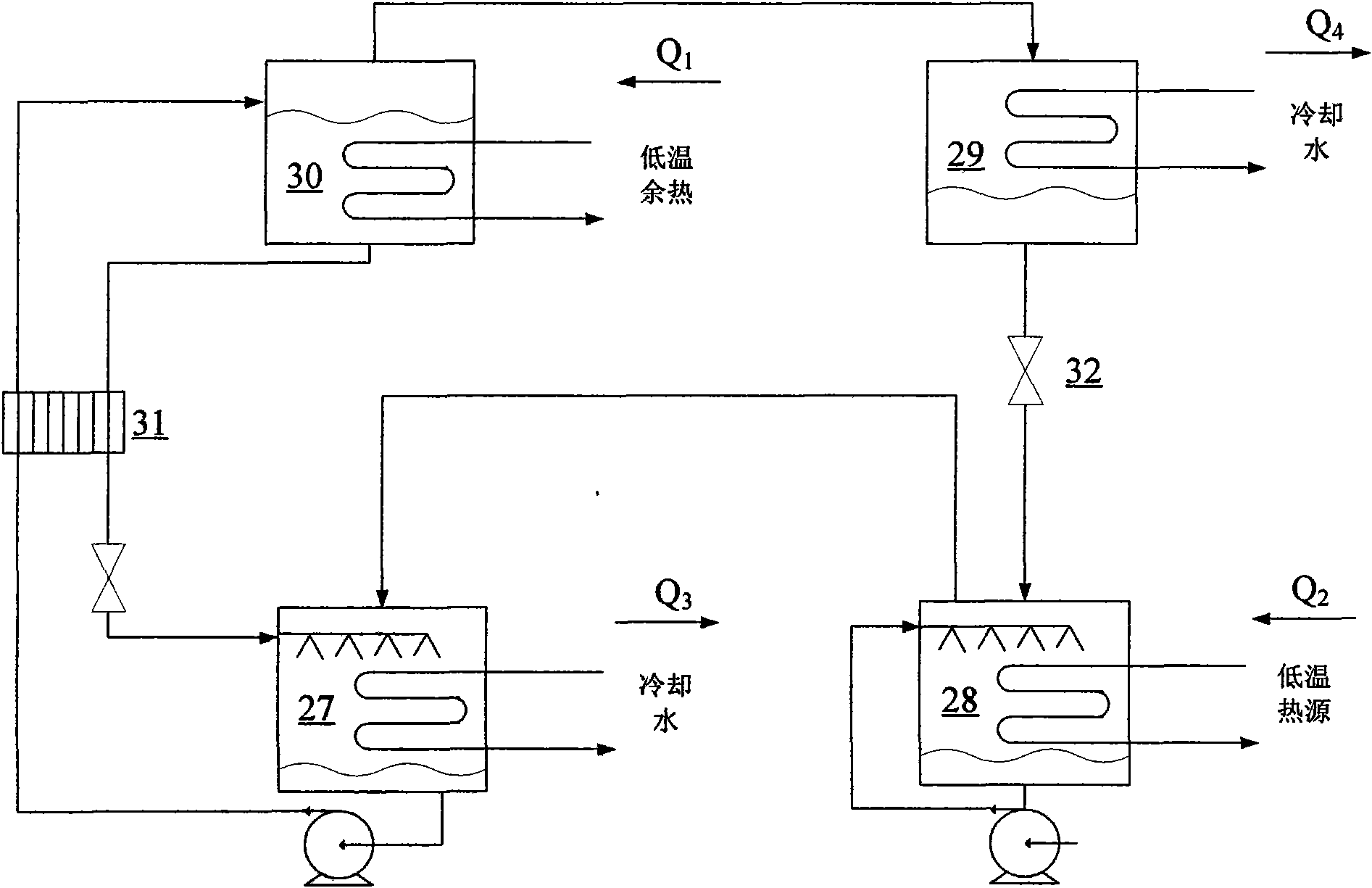

[0027] Referring to the Kellogg-type ammonia plant with a production capacity of 62.5t / h, the product unit consumption of this scheme is reduced by 2.5GJ / t compared with the original level. Recover 34t / h of carbon dioxide and 1t / h of argon. It is suitable for energy-saving and emission-reduction technological transformation of the existing natural gas ammonia synthesis device.

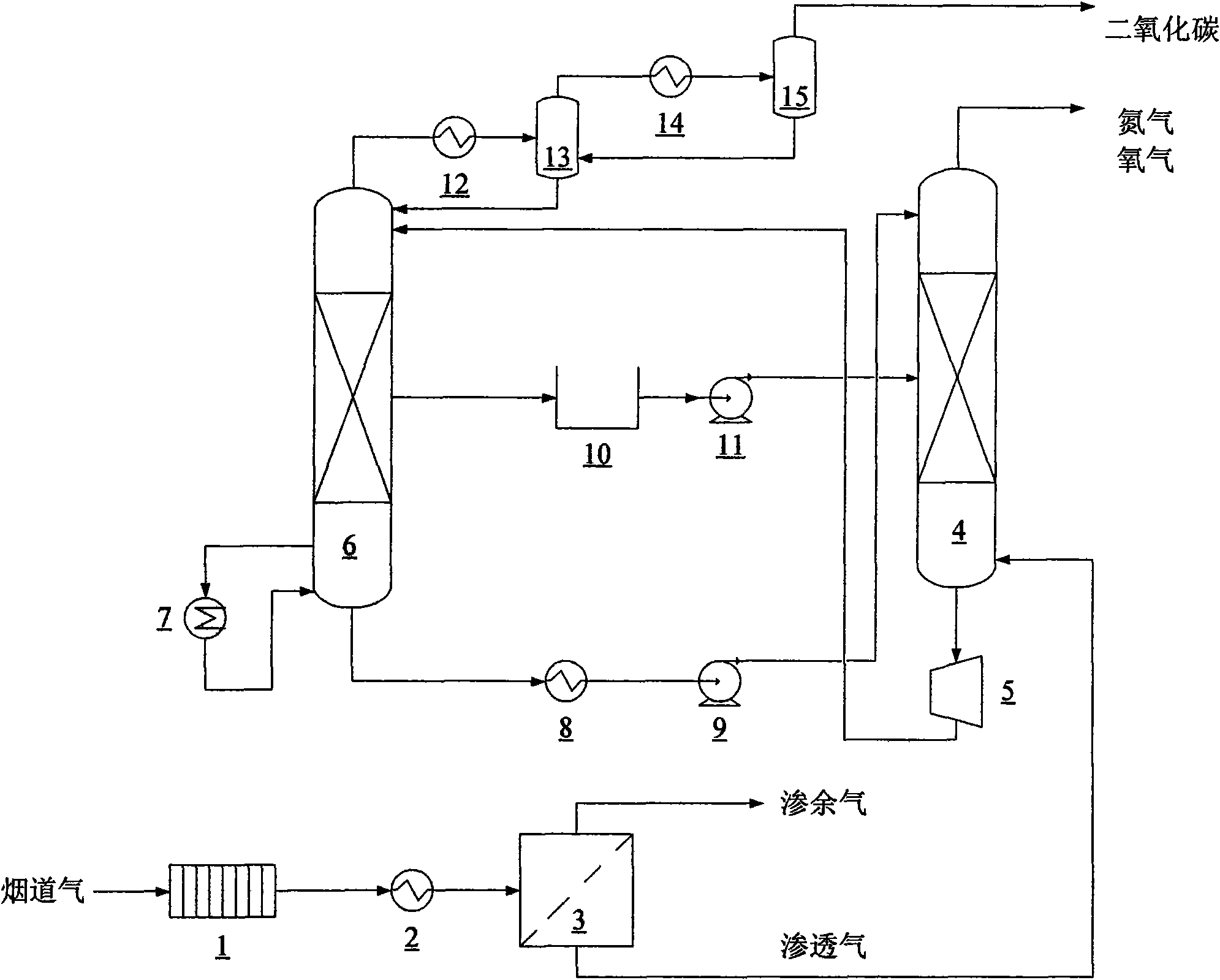

[0028] 1. The carbon dioxide recovery part of the flue gas is detailed as follows:

[0029] The pressurized flue gas with a flow rate of 380t / h is dried and pretreated, and most of the water is removed before entering the membrane separator. Since carbon dioxide passes through the membrane more easily, about 80% of the carbon dioxide enters the permeate gas, and at the same time the carbon dioxide in the permeate gas The concentration has reached ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com