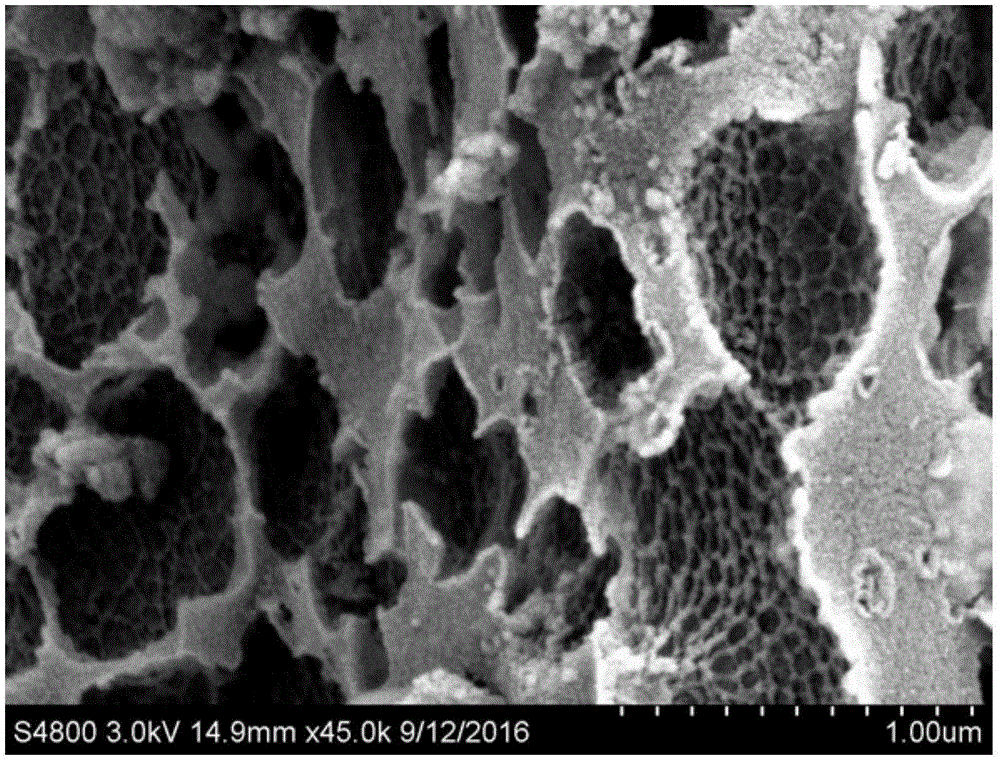

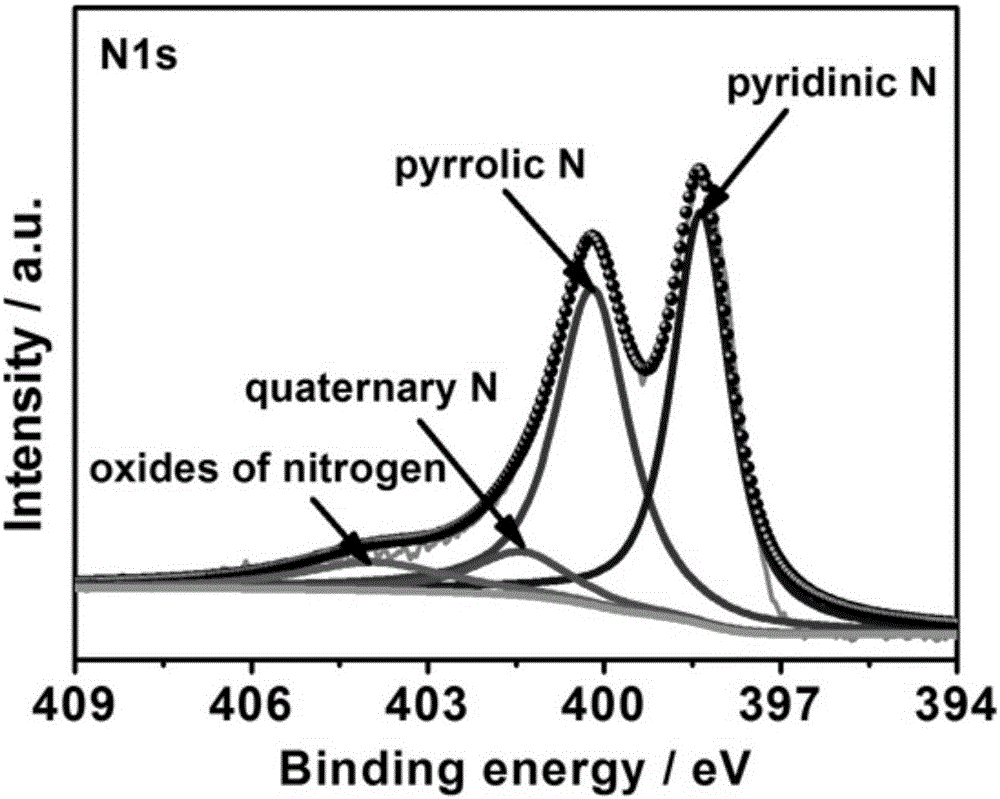

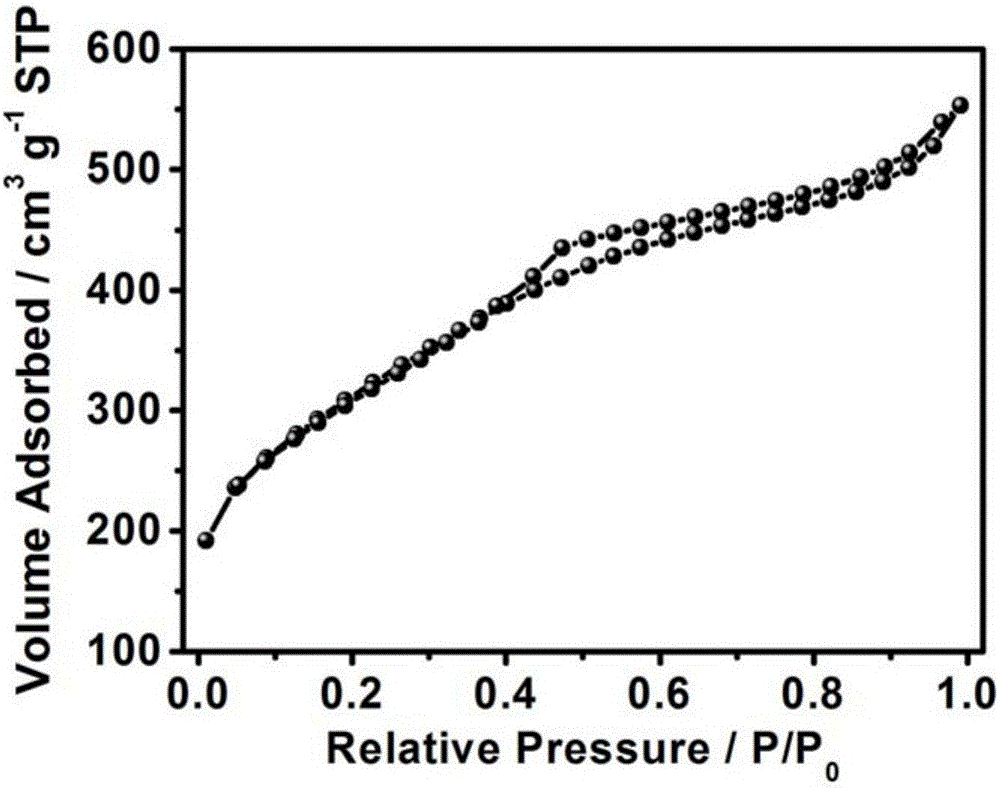

Nitrogen-doped porous carbon and preparation method as well as application of nitrogen-doped porous carbon to super-capacitor electrode material

A technology of porous carbon and nitrogen doping, which is applied in the field of supercapacitor electrodes, preparation, and nitrogen-doped porous carbon. It can solve the problems of limiting the application value of porous carbon reagents, low energy density, etc., and achieve improved pore utilization and high specific capacitance. and energy density, the effect of high electric double layer capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037](1) Take the natural waste peanut shells, wash them in deionized water, dry them in the air, and pre-crumble them with a tissue grinder; then, use deionized water as a dispersant, and use a planetary ball mill to further grind the pre-crushed peanut shells For processing, the rotating speed is 500 rpm, and the ball milling time is 12 hours.

[0038] (2) The slurry after ball milling is sieved through a 250-mesh screen cloth, and the filtrate is centrifuged at a speed of 8000 rpm to obtain a precipitate, which is repeatedly ultrasonically washed 3 times with absolute ethanol and deionized water, and the centrifugal precipitate is subjected to Obtain pretreated peanut shell powder after drying at 50 degrees centigrade.

[0039] (3) Weigh 0.5 grams of peanut shell powder and 1 gram of melamine, grind them evenly, then add 1 gram of potassium hydroxide and 5 milliliters of deionized water to the system, continue to grind until uniform, and transfer them to a drying oven at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com