High-performance carbon-based negative electrode material of lithium ion battery and preparing method thereof

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, batteries, negative electrodes, etc., can solve the problems of hindering the large-scale application of materials, poor conductivity of electrode materials, and matching of electrode characteristics, so as to achieve excellent electrochemical performance and reduce Calcination temperature, effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

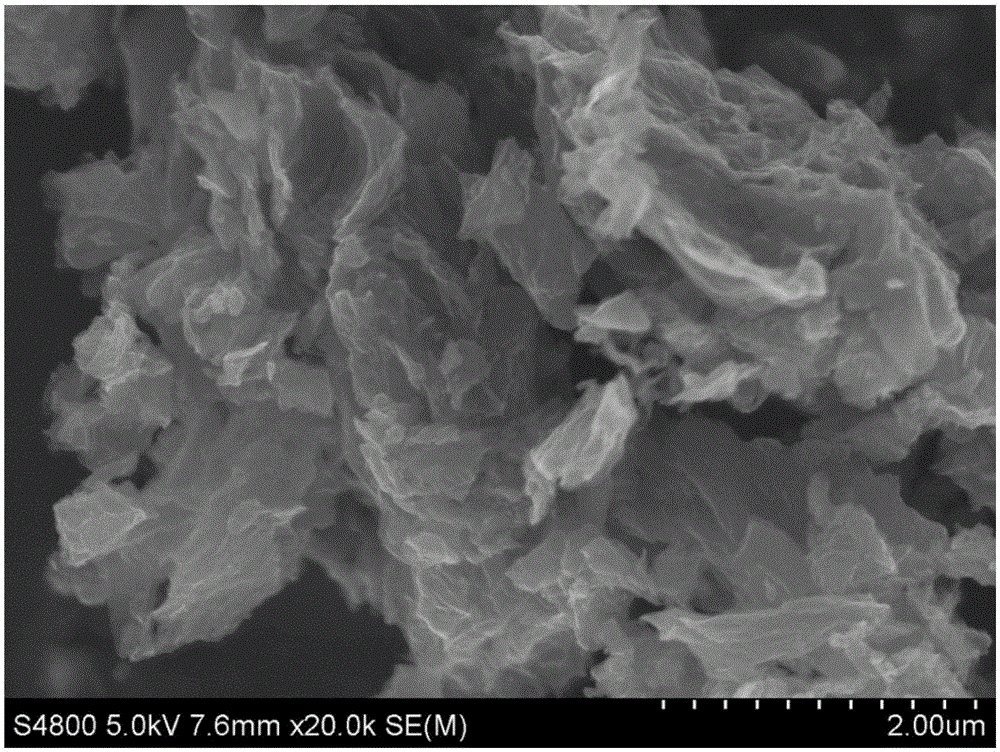

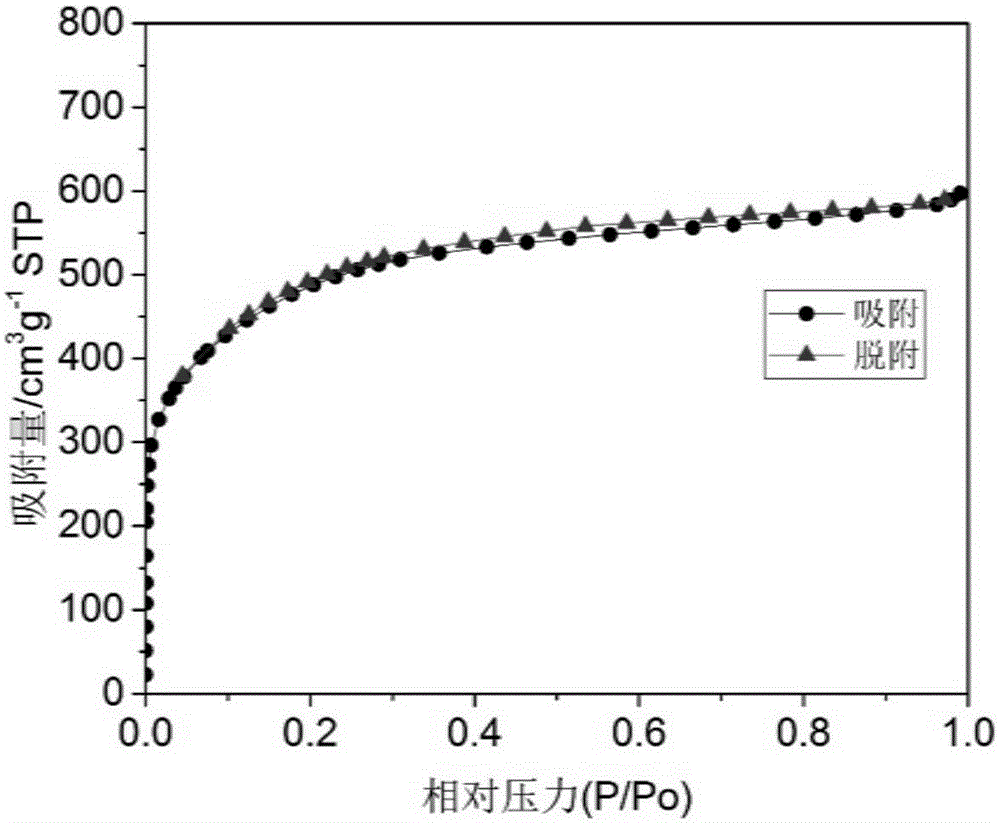

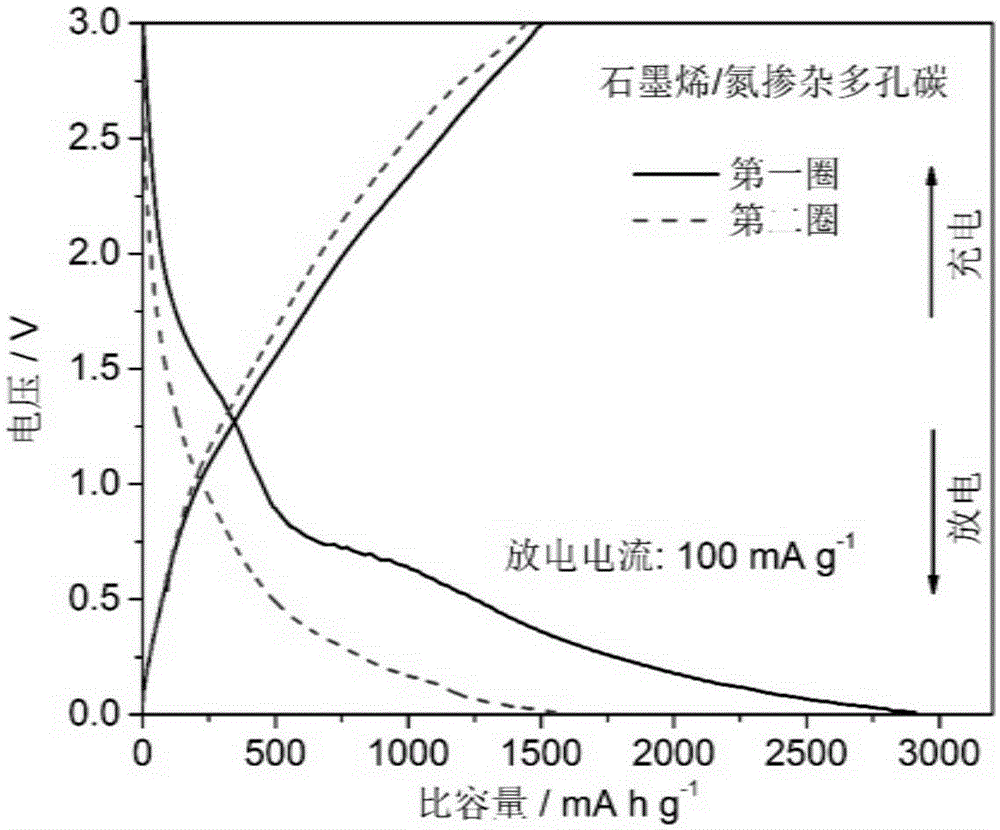

[0031] Example 1: Preparation of graphene / nitrogen-doped porous carbon and electrochemical performance test of assembled simulated battery.

[0032] 0.7g of chitosan was dissolved in 25mL of deionized water, and 5mL of 1mol / L dilute hydrochloric acid was added to help dissolve, fully stirred and dissolved to obtain light yellow clear solution A, wherein the concentration of chitosan was 2.3wt%. 50 mg of graphite oxide was uniformly dispersed in 40 mL of deionized water, and ultrasonically peeled for 2 hours to obtain graphene oxide dispersion B, wherein the concentration of graphite oxide was 0.12 wt%. The solution A and the dispersion B were uniformly mixed and stirred overnight, heated and stirred at 90°C until gelatinous, and then completely dried in a blast drying oven to obtain a precursor powder. Take 0.4g of the precursor and 4g of zinc chloride powder and mix them evenly, then bake them at 600°C for 2 hours under an argon atmosphere, and then wash them repeatedly with ...

Embodiment 2

[0034] Example 2: Preparation of carbon nanotube / nitrogen-doped carbon composite material and electrochemical performance test of assembled simulated battery.

[0035]Dissolve 0.7g chitosan in 115mL deionized water, and add 5mL of 1mol / L dilute hydrochloric acid to help dissolve, fully stir and dissolve to obtain light yellow or colorless clear solution A, wherein the concentration of chitosan is 0.58wt%. Uniformly disperse 50mg of carbon nanotubes in 40mL of deionized water to obtain dispersion B, in which the concentration of carbon nanotubes is 0.2wt%. Mix solution A and dispersion B uniformly and stir overnight, heat and stir at 80°C until gelatinous , and completely dried in a blast drying oven to obtain a precursor powder. Take 0.4g of the precursor and 4g of zinc chloride powder and mix them evenly, then bake them at 600°C for 2 hours under an argon atmosphere, and then wash them repeatedly with 1mol / L dilute hydrochloric acid and deionized water to completely remove th...

Embodiment 3

[0036] Example 3: Preparation of carbon nanotube / porous carbon composite material and electrochemical performance test of assembled simulated battery.

[0037] Dissolve 0.7 g of glucose in 50 mL of deionized water, stir and dissolve to obtain a colorless clear solution A, wherein the concentration of glucose is 1.4 wt%. Uniformly disperse 50mg of carbon nanotubes in 40mL of deionized water to obtain dispersion B, in which the concentration of carbon nanotubes is 0.12wt%. Mix solution A and dispersion B uniformly and stir overnight, heat and stir at 90°C until gel , and completely dried in a blast drying oven to obtain a precursor powder. Take 0.4g of the precursor and 6g of zinc chloride powder and mix them evenly, then bake at 700°C for 3 hours under pure nitrogen atmosphere, and then wash with 1mol / L dilute hydrochloric acid and deionized water repeatedly to completely remove the metal salt impurities in the material , and the final product was obtained after drying, with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com