Foam nickel-loaded nanometer flower spherical carbon and sulfur composite lithium-sulfur battery positive electrode material and preparation method thereof

A carbon-sulfur composite, cathode material technology, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of surface morphology and microscopic characteristics of sulfur cathodes, weakened contact between materials and substrates, and shortened cycle life. Achieving good electron transmission channels, slowing down the decay of capacity, and increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 0.6g of zinc nitrate hexahydrate, 0.6g of urea and 0.15g of ammonium fluoride and dissolve them in 80ml of deionized water, stir until completely dissolved to a transparent state, and prepare a homogeneous solution. Put the homogeneous solution formed above into a polytetrafluoroethylene high-pressure hydrothermal tank, and put a piece of foamed nickel substrate in advance. The hydrothermal tank was sealed in a high-pressure reactor, and the hydrothermal reaction was carried out in an oven at 90° C. for 6 hours. After the reaction is complete, cool to room temperature 25° C., wash with deionized water three times, and place in an oven to dry. Afterwards, it was calcined at 500° C. for 1 hour in argon, and cooled naturally to room temperature 25° C. to prepare zinc oxide nanosheets supported by nickel foam.

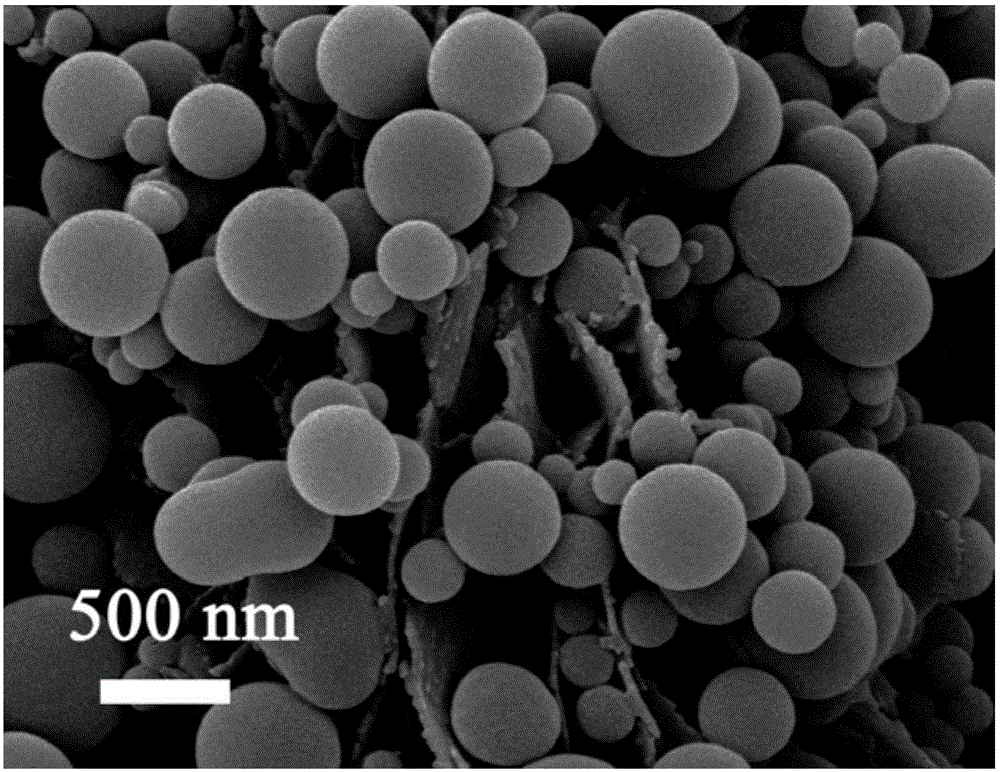

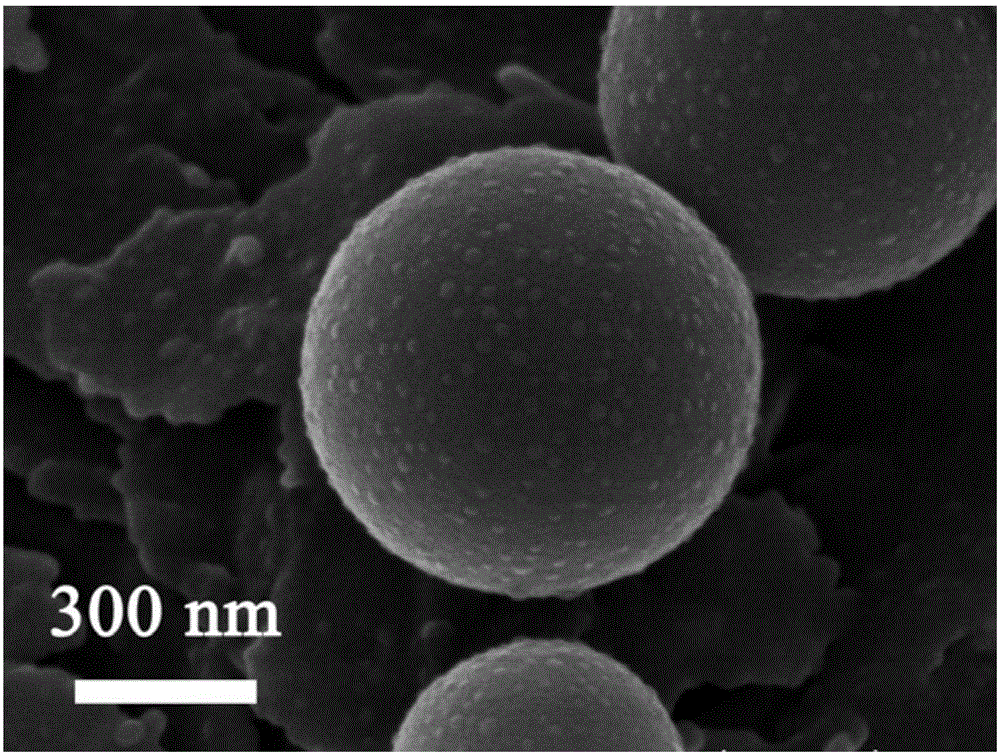

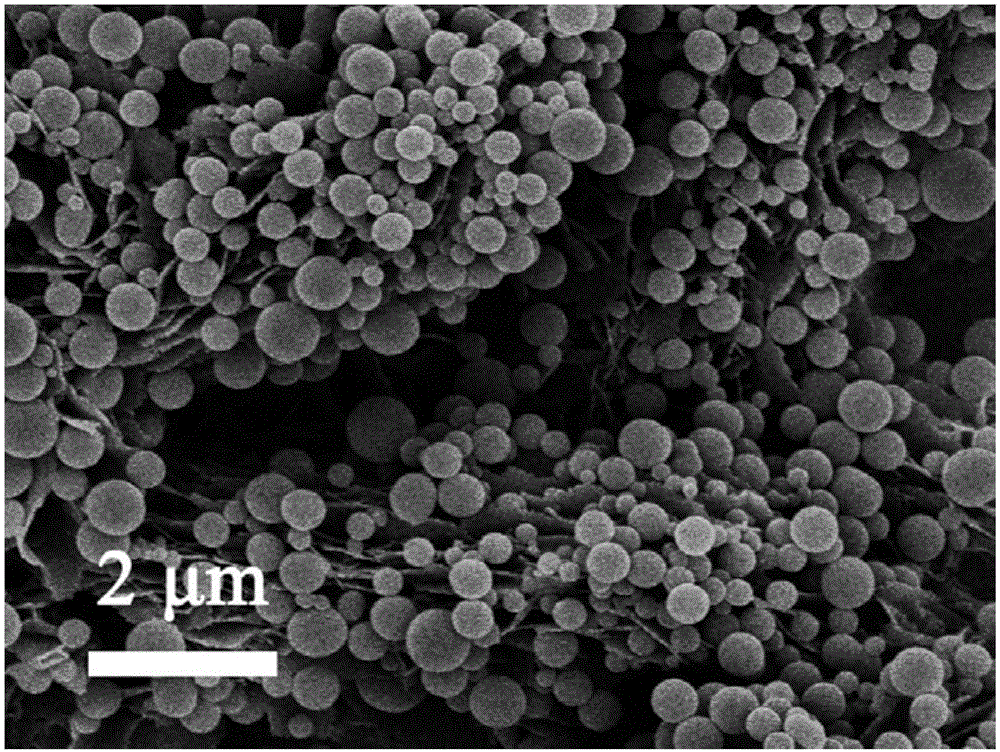

[0037] Put 80ml of glucose aqueous solution with a molar concentration of 0.1mol / L into a polytetrafluoroethylene high-pressure hydrothermal tank, and put zi...

Embodiment 2

[0040] Weigh 1.2g of zinc nitrate hexahydrate, 1.2g of urea and 0.3g of ammonium fluoride, dissolve them in 80ml of deionized water, stir until completely dissolved to a transparent state, and prepare a homogeneous solution. Put the homogeneous solution formed above into a polytetrafluoroethylene high-pressure hydrothermal tank, and put a piece of foamed nickel substrate in advance. The hydrothermal tank was sealed in a high-pressure reactor, and the hydrothermal reaction was carried out in an oven at 130° C. for 7.5 hours. After the reaction is complete, cool to room temperature, wash with deionized water three times, and place in an oven to dry. Afterwards, it was calcined at 650° C. for 2 hours in argon, and cooled naturally to room temperature 25° C. to prepare zinc oxide nanosheets supported by nickel foam.

[0041] Put 80ml of glucose aqueous solution with a molar concentration of 1mol / L into a polytetrafluoroethylene high-pressure hydrothermal tank, and put zinc oxide ...

Embodiment 3

[0044] Weigh 1.8 g of zinc nitrate hexahydrate, 1.8 g of urea and 0.45 g of ammonium fluoride and dissolve them in 80 ml of deionized water, stir until completely dissolved to a transparent state, and prepare a homogeneous solution. Put the homogeneous solution formed above into a polytetrafluoroethylene high-pressure hydrothermal tank, and put a piece of foamed nickel substrate in advance. The hydrothermal tank was sealed in a high-pressure reactor, and the hydrothermal reaction was carried out in an oven at 150° C. for 9 hours. After the reaction is complete, cool to room temperature, wash with deionized water three times, and place in an oven to dry. Afterwards, it was calcined in argon at 800° C. for 3 hours, and cooled naturally to room temperature of 25° C. to prepare zinc oxide nanosheets supported by nickel foam.

[0045] Put 80ml of glucose aqueous solution with a molar concentration of 2mol / L into a polytetrafluoroethylene high-pressure hydrothermal tank, and put zi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com