Nanometer titania photocatalyst for degrading VOC and preparation method of nanometer titania photocatalyst for degrading VOC

A nano-titanium dioxide and photocatalyst technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, separation methods, etc., can solve the problems of complex preparation process and low concentration of benzene degradation, and achieve simple process operation, low cost, Ease of promoting the effect of the application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

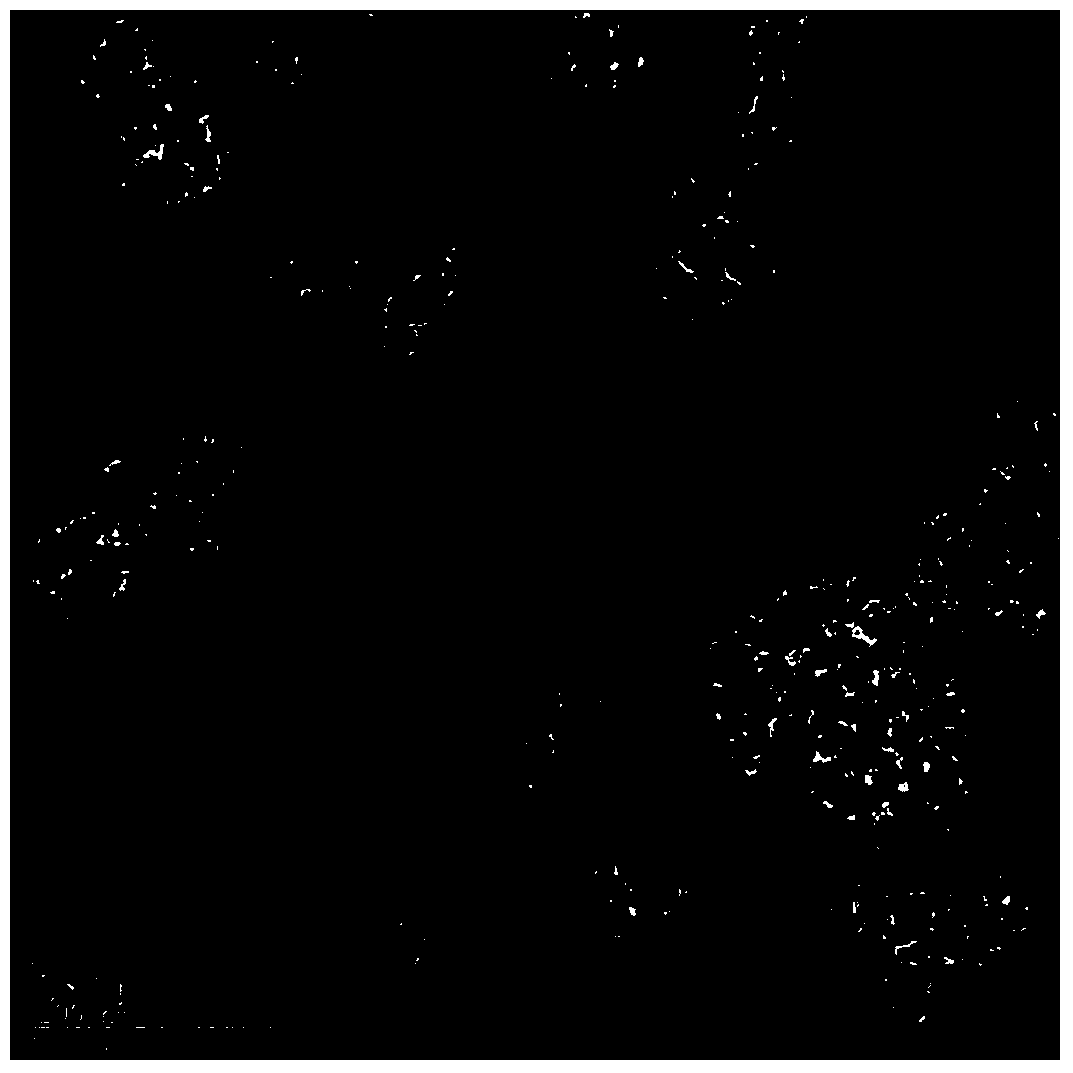

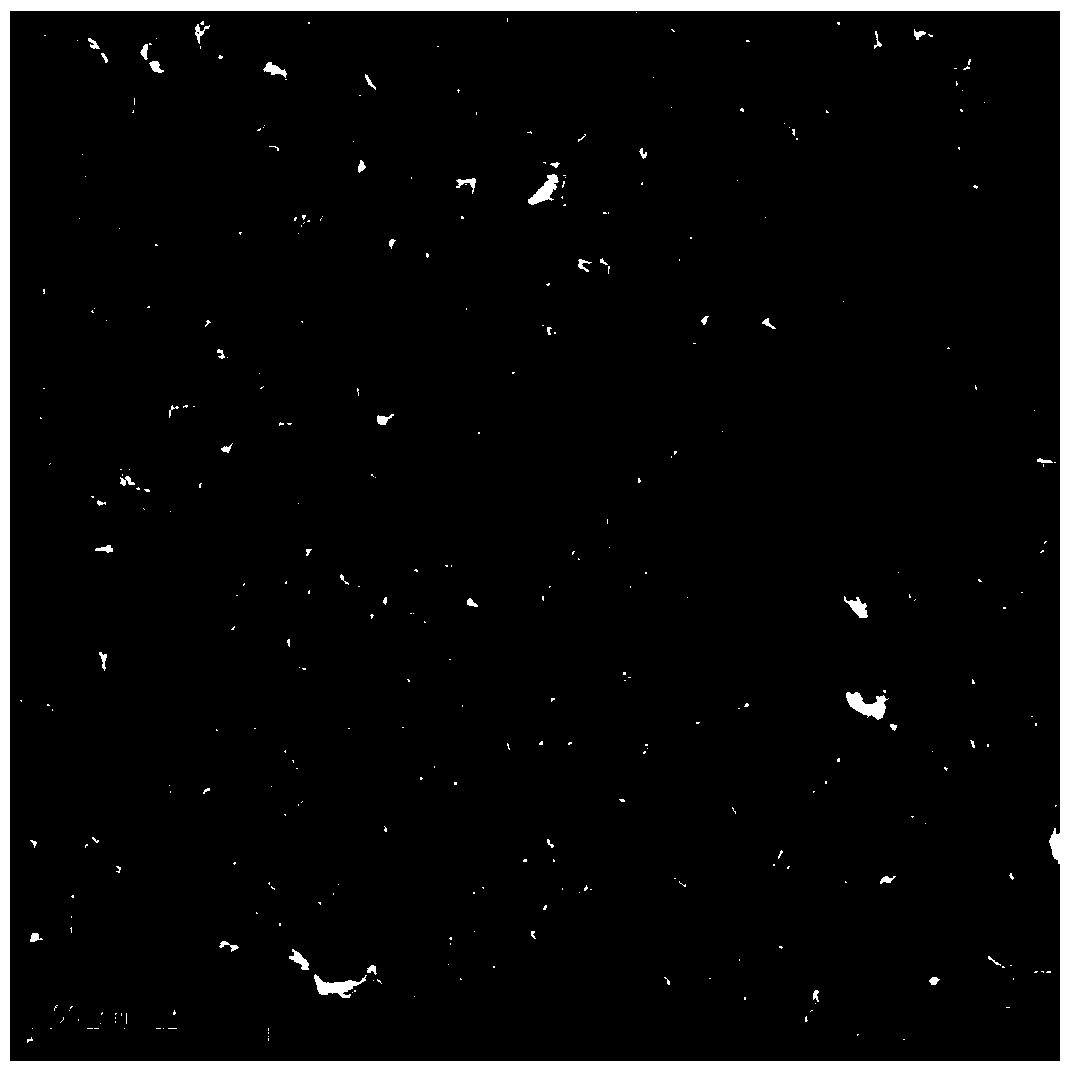

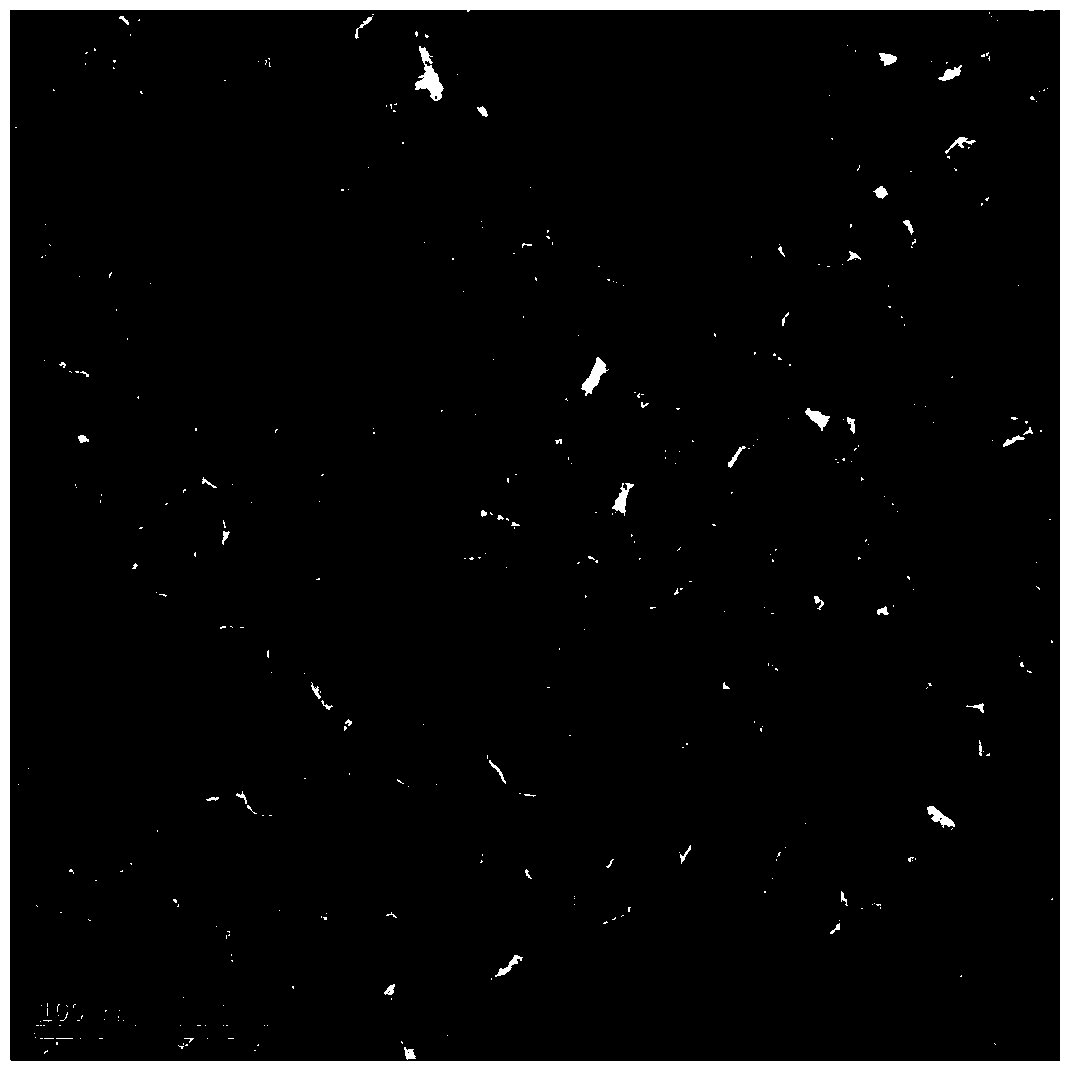

Image

Examples

Embodiment 1

[0031] S1: Place the sample, in which the nano-sized titanium dioxide prepared by the hydrothermal method is first put into the tube furnace to spread as much as possible on the ark where the sample is placed, and the thickness does not exceed 0.1 cm. The model of the tube furnace is tube OTF-1200X, with a maximum power of 2.5KW. The particle size of the nano titanium dioxide is 10 nm, and the nano titanium dioxide is prepared by hydrothermally using tetrabutyl titanate as a precursor at 160° C. for 12 hours. Blow in ammonia gas with a purity of 99.9% for 30 minutes, and the flow rate of ammonia gas is 100mL / min, at this time all the air in the tube furnace is discharged;

[0032] S2: Atmospheric calcination, in which the heating program of the tube furnace is set first, and the furnace body is raised to 550°C at a heating rate of 4°C / min and kept for 2 hours. The process is continuously fed with ammonia gas, and the flow rate of ammonia gas is 100mL / min;

[0033] S3: Vacuum cal...

Embodiment 2

[0036] The steps in this embodiment are the same as those in embodiment 1, except that:

[0037] In S1, the particle size of nano titanium dioxide is 13 nm, and ammonia gas with a purity of 99.99% is introduced.

[0038] In S2, the heating rate of the tube furnace is 6°C / min, the furnace body is heated to 600°C and kept for 4 hours, and the flow rate of ammonia gas is 200mL / min;

[0039] In S3, the vacuum degree of heat preservation is 50KPa, the heat preservation time is 3 hours, the heat preservation temperature is 600℃, and the flow rate of ammonia gas is 200mL / min;

[0040] In S4, the vacuum degree is maintained at 50KPa, and the sample is taken out to obtain the nano titanium dioxide photocatalyst.

Embodiment 3

[0042] The steps in this embodiment are the same as those in embodiment 1, except that:

[0043] In S1, the particle size of nano titanium dioxide is 15 nm, and ammonia gas with a purity of 99.999% is introduced.

[0044] In S2, the heating rate of the tube furnace is 7°C / min, the furnace body is heated to 650°C and kept for 3 hours, and the flow rate of ammonia gas is 350mL / min;

[0045] In S3, the vacuum degree of heat preservation is 20KPa, the heat preservation time is 4 hours, the heat preservation temperature is 650℃, and the flow rate of ammonia gas is 350mL / min;

[0046] In S4, the vacuum degree is maintained at 20Kpa, and the sample is taken out to obtain the nanometer titanium dioxide photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Average particle size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com