Treatment method for improving spinnability and whiteness of linen fiber

A flax fiber and processing method technology, which is applied in the processing field of improving the spinnability and whiteness of flax fiber, can solve the problems of large dosage of reagents, poor fiber quality and spinnability, long processing time, etc., so as to improve the spinnability, The effect of increasing fiber whiteness, reducing usage and emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

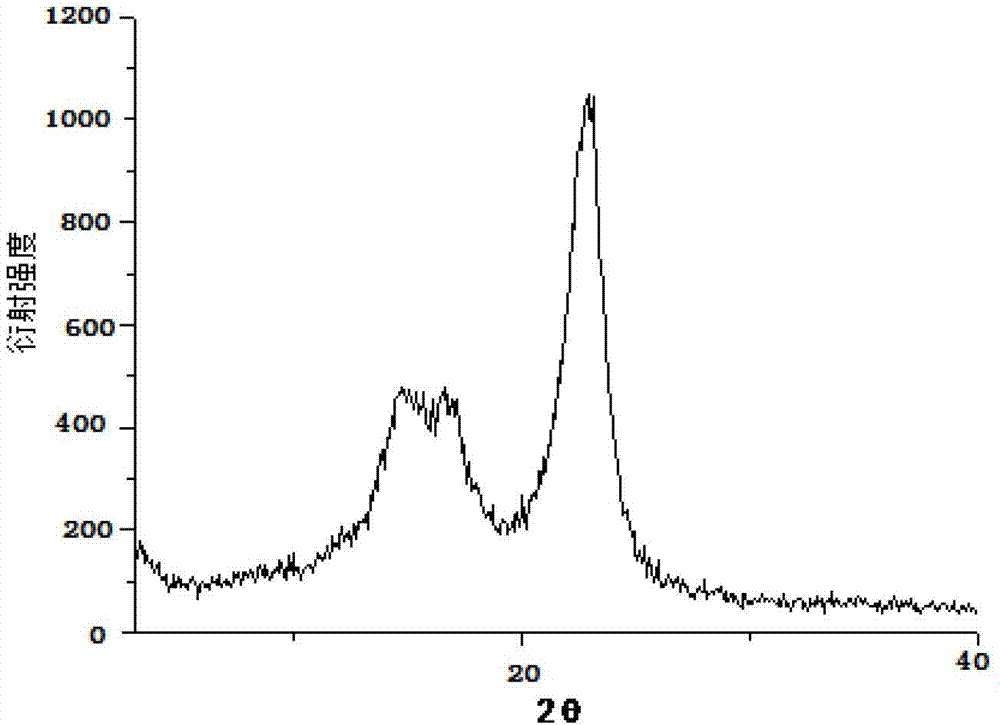

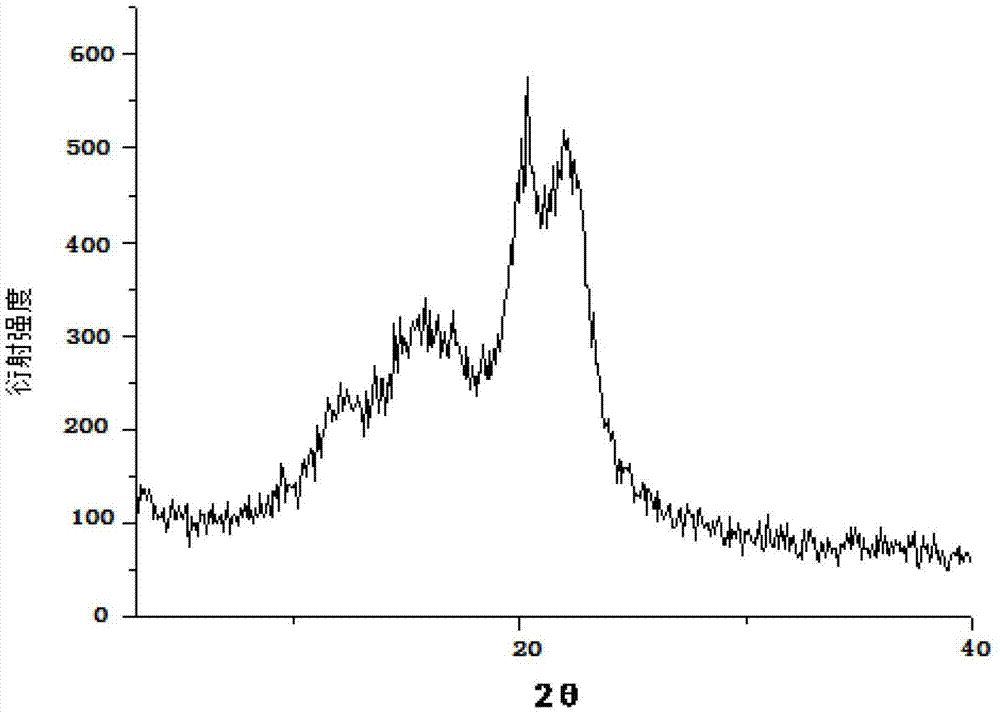

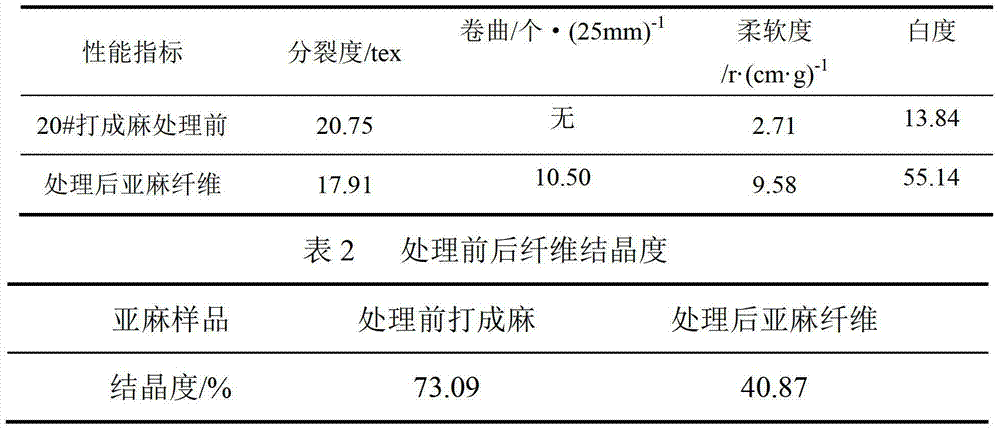

[0072] The flax fibers are pretreated to be loosened into fibers and impurities are removed at the same time; under ultrasonic conditions, the obtained fibrous flax fibers are immersed in a NaOH solution with a temperature of 50°C and a mass concentration of 10%. Alkali soaking treatment was carried out for 30 minutes, wherein, the bath ratio of flax fiber and NaOH solution was 1:10, and the frequency of ultrasonic waves was 28KHz; put the flax fiber after alkali soaking treatment into a centrifugal dehydrator for dehydration treatment for 3-5 minutes , to remove the lye; then immerse the dehydrated flax fibers into a mixture of sulfuric acid mass-volume concentration of 10g / L, sodium sulfate mass-volume concentration of 60g / L and zinc sulfate mass-volume concentration of 15g / L The acid bath treatment is carried out in the solution for 10 minutes, wherein, the bath ratio of the flax fiber to the mixed solution is 1:10, and the acid bath treatment temperature is 40-50°C; the fla...

Embodiment 2

[0077] The flax fibers are pretreated, loosened into fibers, and impurities are removed at the same time; under ultrasonic conditions, the obtained fibrous flax fibers are immersed in a NaOH solution with a temperature of 20°C and a mass concentration of 15%. Alkali soaking treatment was carried out for 45 minutes, wherein, the bath ratio of flax fiber and NaOH solution was 1:20, and the frequency of ultrasonic waves was 40KHz; put the flax fiber after alkali soaking treatment into a centrifugal dehydrator for dehydration treatment for 3-5 minutes , to remove the lye; then immerse the dehydrated flax fiber into a mixture of sulfuric acid mass-volume ratio of 15g / L, sodium sulfate mass-volume ratio of 90g / L and zinc sulfate mass-volume ratio of 20g / L Perform acid bath treatment in the solution for 10 minutes, wherein the bath ratio of the flax fiber to the mixed solution is 1:20, and the acid bath treatment temperature is 40°C; inject clean water into the acid bath treated flax ...

Embodiment 3

[0079] The flax fibers are pretreated, loosened into fibers, and impurities are removed at the same time; under ultrasonic conditions, the obtained fibrous flax fibers are immersed in a NaOH solution with a temperature of 80°C and a mass concentration of 20%. Alkali soaking treatment was carried out for 15 minutes, wherein, the bath ratio of flax fiber and NaOH solution was 1:20, and the frequency of ultrasonic waves was 28KHz; put the flax fiber after alkali soaking treatment into a centrifugal dehydrator for dehydration treatment for 3-5 minutes , to remove the lye; then immerse the dehydrated flax fibers into a mixture of sulfuric acid mass-volume ratio of 25g / L, sodium sulfate mass-volume ratio of 90g / L and zinc sulfate mass-volume ratio of 25g / L The acid bath treatment is carried out in the solution for 15 minutes, wherein, the bath ratio of the flax fiber to the mixed solution is 1:20, and the acid bath treatment temperature is 40-50°C; the flax fiber treated by the acid ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com