Automobile hub (HUB) and manufacturing method thereof

A technology of automobile wheel hub and manufacturing method, which is applied in the direction of wheels, vehicle parts, transportation and packaging, etc., to achieve the effect of improving mechanical properties and saving material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

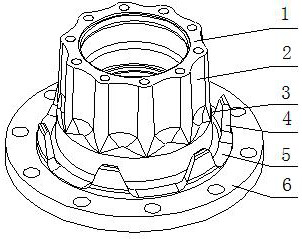

[0042] Such as figure 1 As shown, the appearance structure of the automobile wheel hub (HUB) of the present invention is exactly the same as the macroscopic structure of the automobile wheel hub (HUB) in the prior art. Such as figure 1 As shown, its main body is a sleeve-shaped structure, and the central round hole is used to connect with the automobile half shaft. The main structure is in the shape of a "T", and the small end thereof is provided with a screw hole as a small flange 1, which is used for threaded connection with the dust cover during installation. The big end is provided with a screw hole, which is used as a big flange 6 to be connected with a wheel and a brake hub during installation. The main body sleeve 2 is used for torque transmission and support, and keeps the overall structure stable.

[0043] On the periphery of the main body sleeve 2, close to the inside of one end of the large flange 6, a plurality of connecting blocks 4 are arranged in the coaxial ...

Embodiment 2

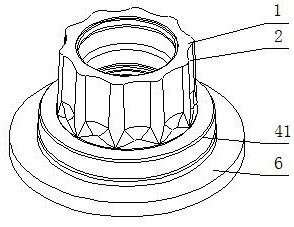

[0060] Embodiment 2: as figure 1 The wheel hub with the structure shown in this embodiment is basically the same as that of Embodiment 1, the difference is that the connecting block 4 is not formed by spinning after forging, but is formed by milling, cutting and finishing after forging, but the connection The clamping block 4 has structural features formed by forging. The specific production process is as follows: image 3 Semi-finished shape shown. An annular platform 41 is formed in the semi-finished product, and then the annular platform 41 is milled to form the structure of the annular groove 3 . The cutting operation is performed again to form the notch 5 , and then the connecting block 4 is formed. Although the product of this method and structure cannot reach the mechanical strength of the spinning part of Example 1, it basically meets the characteristics and mechanical strength of the forging structure, which is higher than that of the product formed by casting.

...

Embodiment 3

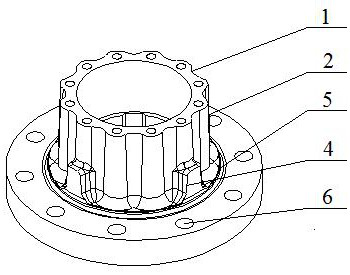

[0062] Embodiment 3: The structure of the forged automobile hub (HUB) of this embodiment is as follows figure 2 As shown, the structure is basically the same as that of Embodiment 1, the difference is that there is no annular groove 3 between the connecting block 4 and the outer wall 2 of the main body sleeve, which is a solid connection state, which is formed during the forging process. formed in one. Products with this structure can also achieve the mechanical properties of forged products, but the weight of the product is slightly increased, and the weight of the finished product is 14.5 kg. The product of this embodiment is also formed through material selection and three-step forging.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com