Method for preparing Ni/CeO2 composite hydrogen evolution electrode

A hydrogen evolution electrode and electrodeposition technology, applied in electrodes, electrolytic coatings, electrolytic processes, etc., can solve problems such as hindering metal ions, affecting the performance and stability of catalytic hydrogen evolution, and micro-cracks, improving hydrogen evolution performance, and overcoming conventional composite electrodes. effect of deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Pretreatment of substrate

[0031] Before electrodeposition, the metal copper foil substrate is subjected to mechanical grinding, alkali washing to degrease, weak acid etching, and then washed and dried for use.

[0032] (2) Preparation of plating solution

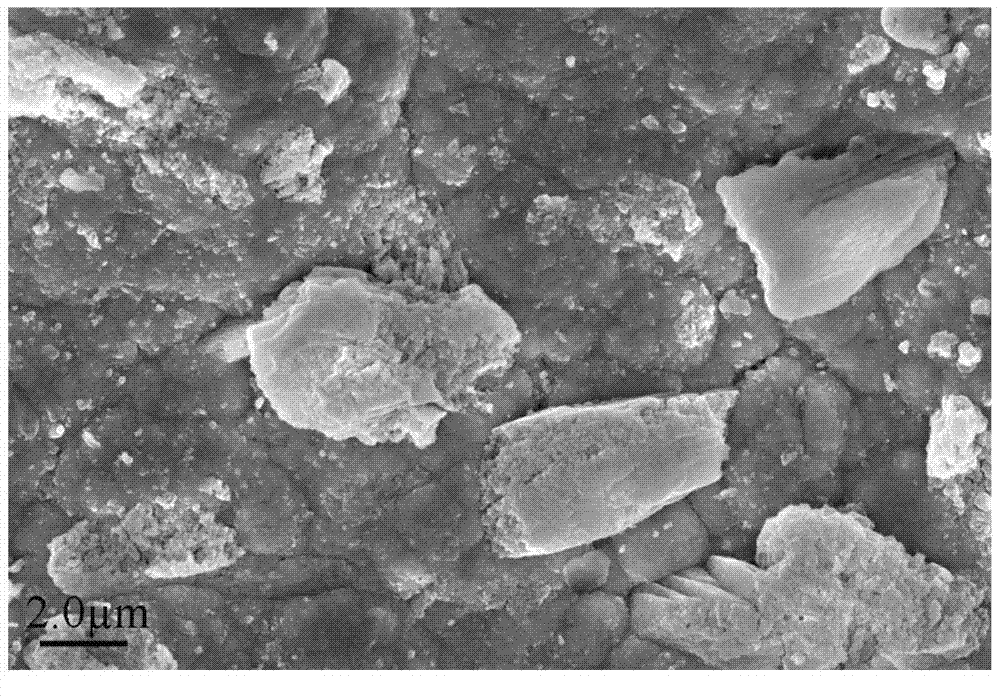

[0033] Each liter of plating solution contains 350g of nickel sulfamate, 20g of nickel chloride, 30g of ammonium chloride, 0.1g of sodium lauryl sulfate, and CeO with a particle size of 5 μm 2 The particles are 9g, and the pH value of the plating solution is 3.5.

[0034] (3)CeO 2 particle dispersion

[0035] CeO 2 The particles were added to the plating solution, then sonicated for 3 h, followed by stirring with a magnetic stirrer at 600 rpm for 24 h to make the CeO 2 Particles are evenly dispersed in the bath to reduce agglomeration.

[0036] (4) Preparation of Ni / CeO by high-gravity electrodeposition 2 Compound electrode

[0037] The high-gravity electrodeposition process is carried out in a cylindric...

Embodiment 2

[0041] (1) Pretreatment of substrate

[0042] Before electrodeposition, the metal copper foil substrate is subjected to mechanical grinding, alkali washing to degrease, weak acid etching, and then washed and dried for use.

[0043] (2) Preparation of plating solution

[0044] Each liter of plating solution contains 350g of nickel sulfamate, 20g of nickel chloride, 30g of ammonium chloride, 0.1g of sodium lauryl sulfate, and CeO with a particle size of 5 μm 2 The particles are 9g, and the pH value of the plating solution is 3.5.

[0045] (3)CeO 2 particle dispersion

[0046] CeO 2 The particles were added to the plating solution, then sonicated for 3 h, followed by stirring with a magnetic stirrer at 600 rpm for 24 h to make the CeO 2 Particles are evenly dispersed in the bath to reduce agglomeration.

[0047] (4) Preparation of Ni / CeO by high-gravity electrodeposition 2 Compound electrode

[0048] The high-gravity electrodeposition process is carried out in a cylindric...

Embodiment 3

[0052] (1) Pretreatment of substrate

[0053] Before electrodeposition, the metal copper foil substrate is subjected to mechanical grinding, alkali washing to degrease, weak acid etching, and then washed and dried for use.

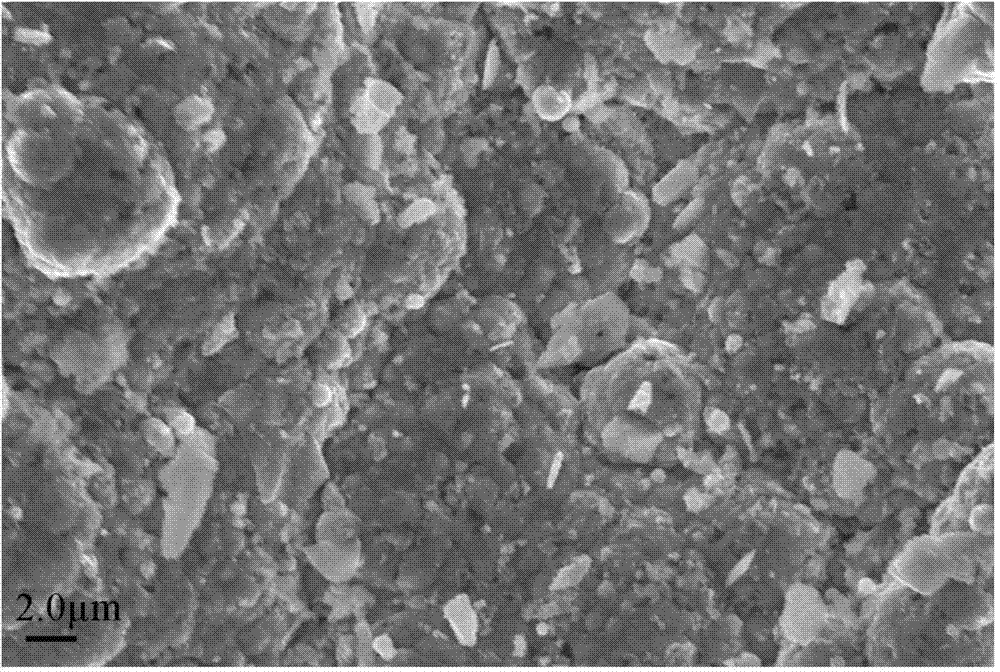

[0054] (2) Preparation of plating solution

[0055] Each liter of plating solution contains 350g of nickel sulfamate, 20g of nickel chloride, 30g of ammonium chloride, 0.1g of sodium lauryl sulfate, and CeO with a particle size of 2μm 2 Particles 7g, pH value of the plating solution is 3.5.

[0056] (3)CeO 2 particle dispersion

[0057] CeO 2 The particles were added to the plating solution, then sonicated for 3 h, followed by stirring with a magnetic stirrer at 600 rpm for 24 h to make the CeO 2 Particles are evenly dispersed in the bath to reduce agglomeration.

[0058] (4) Preparation of Ni / CeO by high-gravity electrodeposition 2 Compound electrode

[0059] The high-gravity electrodeposition process is carried out in a cylindrical reactor with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com