A kind of flexible current collector and lithium battery made of this current collector

A technology of current collectors and positive current collectors, applied in the field of flexible lithium batteries, can solve the problem of not finding relevant patents, and achieve the effects of high mass energy density, cost reduction, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

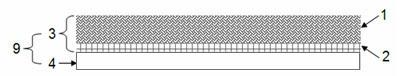

[0021] positive electrode: Using LiMn 2 o 4 As the positive electrode material 4, mix it with PVDF1 and acetylene black to prepare a positive electrode slurry, and then apply the positive electrode slurry on the aluminized polyethylene plastic 3 with an aluminum layer 2 thickness of 1 μm and an industrial plastic 1 thickness of 10 μm. 0.15mm at 120 o C drying in a vacuum oven to obtain the positive electrode sheet.

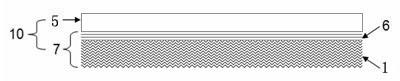

[0022] negative electrode : graphite material is used as the negative electrode material 5, mixed with PVDF and VGCF to prepare the negative electrode material, and then the negative electrode slurry is coated on the copper-coated polyethylene plastic 7 with a copper layer 6 thickness of 0.7 μm and an industrial plastic 1 thickness of 10 μm, Coating thickness is 0.08mm, at 100 o C drying in a vacuum oven to obtain the negative electrode sheet.

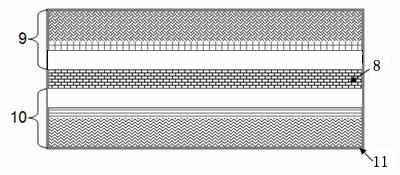

[0023] The above-mentioned positive pole piece 9, negative pole piece 10 and PE separator 8 are according to i...

Embodiment 2

[0033] positive electrode: Using LiCoO 2 As a positive electrode material, mix it with PVDF and Super-P to prepare a positive electrode slurry, and then apply the positive electrode slurry to an aluminized polyvinyl chloride plastic with an aluminum layer thickness of 2 μm and a plastic thickness of 20 μm, with a coating thickness of 0.18mm , at 100 o C drying in a vacuum oven to obtain the positive electrode sheet.

[0034] negative electrode : Graphite material is used as the negative electrode material, mixed with PTFE and acetylene black to prepare the negative electrode material, and then the negative electrode slurry is coated on copper-coated polyvinyl chloride plastic with a copper layer thickness of 1.5 μm and a plastic thickness of 20 μm. 0.12mm at 120 o C drying in a vacuum oven to obtain the negative electrode sheet.

[0035] The above-mentioned positive pole piece, negative pole piece and PE diaphragm are according to image 3 Laminated in the same way, af...

Embodiment 3

[0045] Positive electrode preparation: Using LiMn 2 o 4 As the positive electrode material, the positive electrode slurry was prepared by mixing with PVDF and VGCF, and then the positive electrode slurry was coated on the aluminized polypropylene plastic with an aluminum layer thickness of 1.5 μm and a plastic thickness of 15 μm, with a coating thickness of 0.15 mm. 120 o C drying in a vacuum oven to obtain the positive electrode sheet.

[0046] Negative electrode preparation : Graphite material is used as the negative electrode material, mixed with PVDF and acetylene black to prepare the negative electrode material, and then the negative electrode slurry is coated on the copper-plated polypropylene plastic with a copper layer thickness of 1.0 μm and a plastic thickness of 22 μm. The coating thickness is 0.13mm at 100 oC drying in a vacuum oven to obtain the negative electrode sheet.

[0047] The above-mentioned positive pole piece, negative pole piece and PP diaphragm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com