Current collector, pole piece and battery

A current collector and pole piece technology, which is applied in the field of batteries, can solve problems such as explosion, combustion of combustible substances such as electrolytes, and battery heating, and achieve the effects of increasing energy density, preventing thermal runaway, and reducing metal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The difference from Comparative Example 1 is:

[0058] Preparation of positive electrode sheet:

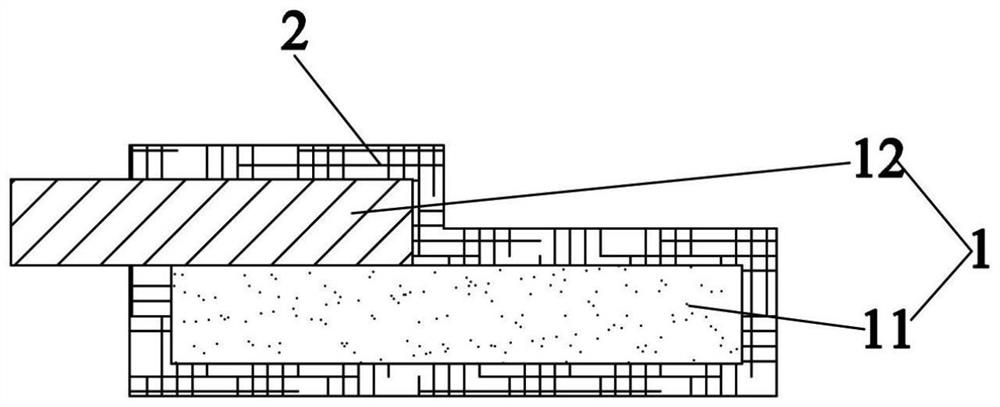

[0059] 1) Partially bond an aluminum foil (metal material layer) with a thickness of 9 μm on one surface of a PET film (polymer layer) with a thickness of 12 μm to form a base layer, and grow on the surface of the PET film and part of the aluminum foil surface by vacuum evaporation An aluminum coating (conductive layer) with a thickness of 2 μm is obtained as figure 1 The positive current collector shown;

[0060] 2) Mix NCM523 powder, SP conductive carbon black, VGCF carbon nanofiber and PTFE at a ratio of 92:3:3:2, dissolve in a solvent and stir evenly to form a positive electrode slurry, and coat the positive electrode slurry on the positive electrode current collector On the aluminum coating layer, dry and roll to form a pole piece with a thickness of 120μm, in which the coating amount of the positive electrode slurry per unit area is 17.8mg / cm 2 .

[0061] The rest...

Embodiment 2

[0063] The difference from Comparative Example 1 is:

[0064] Preparation of positive electrode sheet:

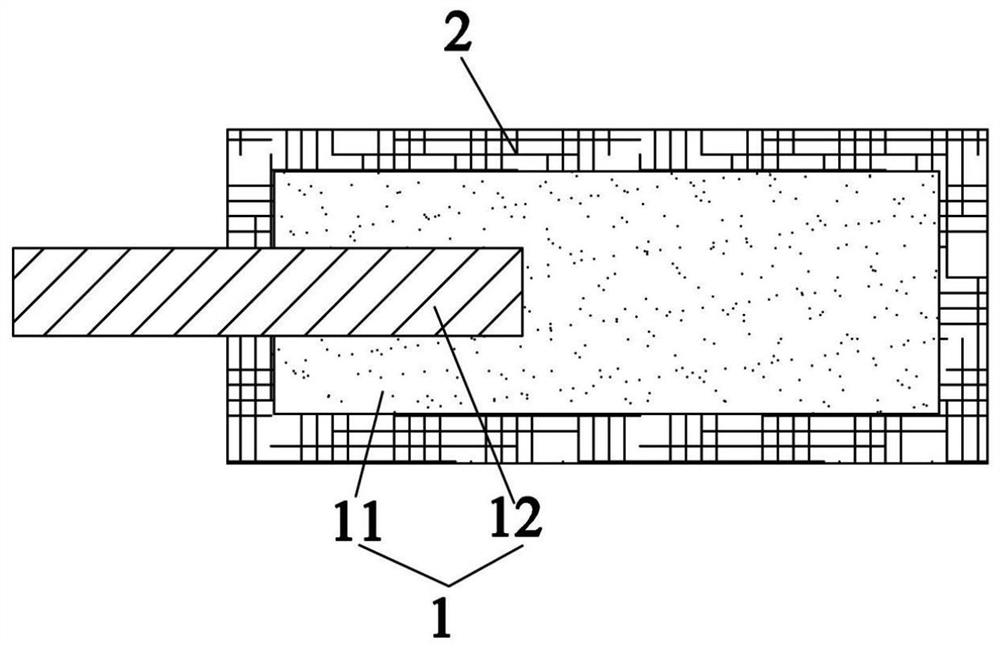

[0065] 1) Take an aluminum foil (metal material layer) with a thickness of 9 μm, and cover a part of its surface with a PET polymer layer with a thickness of 12 μm, so that the aluminum foil is partially embedded in the end of the PET polymer layer to form a base layer. The plating method grows an aluminum coating with a thickness of 2 μm on the surface of the PET polymer layer and the surface of some aluminum foils to obtain the following: figure 2 The positive current collector shown;

[0066] 2) Mix NCM523 powder, SP conductive carbon black, VGCF carbon nanofiber and PTFE at a ratio of 92:3:3:2, dissolve in a solvent and stir evenly to form a positive electrode slurry, and coat the positive electrode slurry on the positive electrode current collector On the aluminum coating layer, dry and roll to form a pole piece with a thickness of 120μm, in which the coating amount...

Embodiment 3

[0069] The difference from Comparative Example 1 is:

[0070] Preparation of positive electrode sheet:

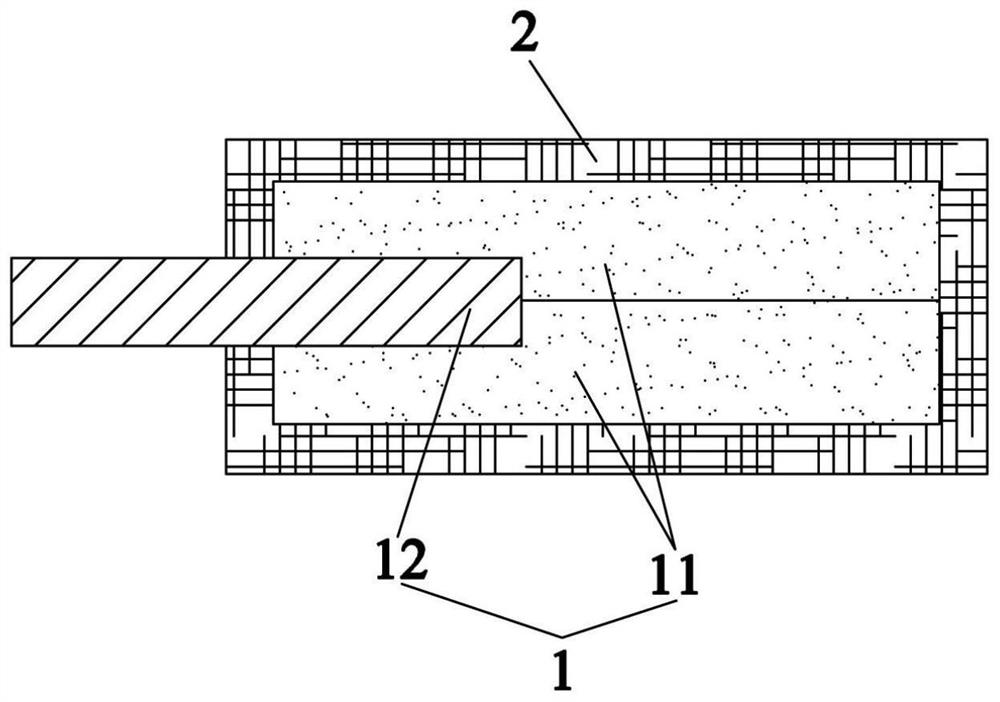

[0071] 1) A part of aluminum foil (metal material layer) with a thickness of 9 μm is sandwiched between two PET films (polymer layer) with a thickness of 5 μm to form a base layer, and the surface and part of the PET film are formed by vacuum evaporation. An aluminum coating with a thickness of 2 μm is grown on the surface of the aluminum foil to obtain the following image 3 The positive current collector shown;

[0072] 2) Mix NCM523 powder, SP conductive carbon black, VGCF carbon nanofiber and PTFE at a ratio of 92:3:3:2, dissolve in a solvent and stir evenly to form a positive electrode slurry, and coat the positive electrode slurry on the positive electrode current collector On the aluminum coating layer, dry and roll to form a pole piece with a thickness of 120μm, in which the coating amount of the positive electrode slurry per unit area is 17.8mg / cm 2 .

[0073] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com