Sterilization treatment device for aseptic packaging system and sterilization treatment method

A disinfection and packaging system technology, applied in the direction of packaging sterilization, packaging, packaging machines, etc., can solve the problems of fracture, brittleness, high energy consumption, etc., and achieve the effect of not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

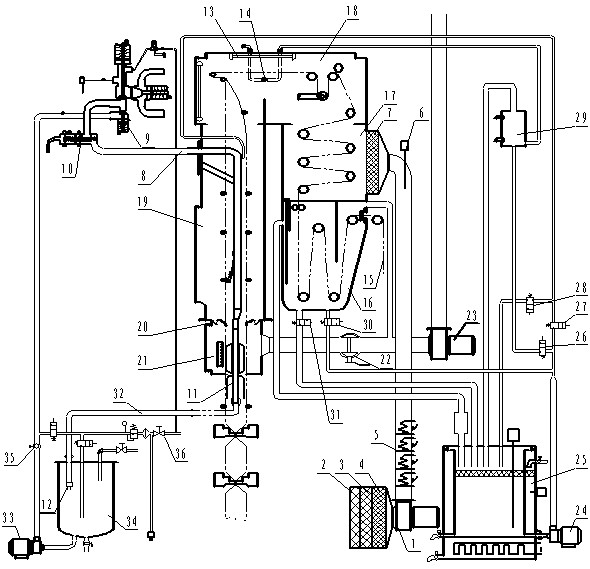

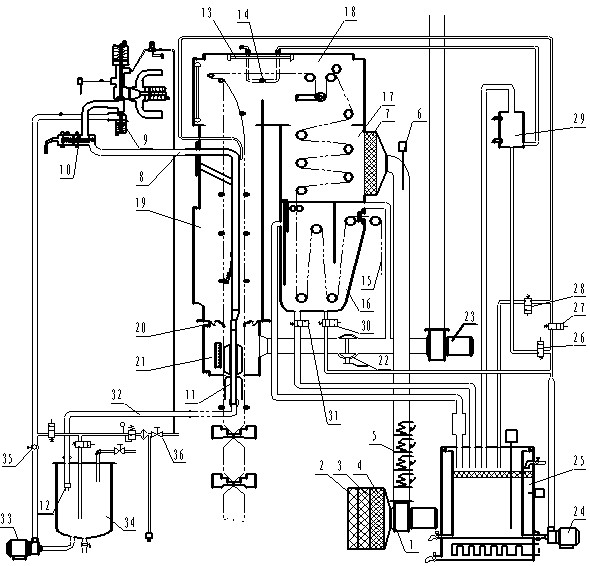

[0031] The sterile air required for sterilization and material filling before aseptic packaging operations is obtained by filtration. A set of three-stage filters consisting of primary filter 2, intermediate filter 3 and fine filter 4 is installed at the air inlet of fan 1, and multiple sets of conical and spiral heaters 5 and temperature sensors 6 are installed in the air supply pipe. An ultra-fine filter 7 is installed at the air outlet of the fan 1, the filtration accuracy is 0.1-0.2 μm, the temperature of the sterile air at the outlet is 45°C, and the flow of the fan is controlled by frequency conversion to achieve multi-stage control to ensure that the sterile room is in a positive pressure state and improve the aseptic condition. Indoor security.

[0032] The sterilization of the machine before aseptic packaging includes two parts: one is steam sterilization of the filling pipe 8, flow control valve 10, and filling parts 11 of the machine. During sterilization, the lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com