Biological mass-energy fuel boiler and its burning method

A technology of biomass energy and combustion method, which is applied to boilers burning biomass fuel and its combustion field, and can solve problems such as high cost and difficulty in realizing comprehensive utilization of ash and slag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

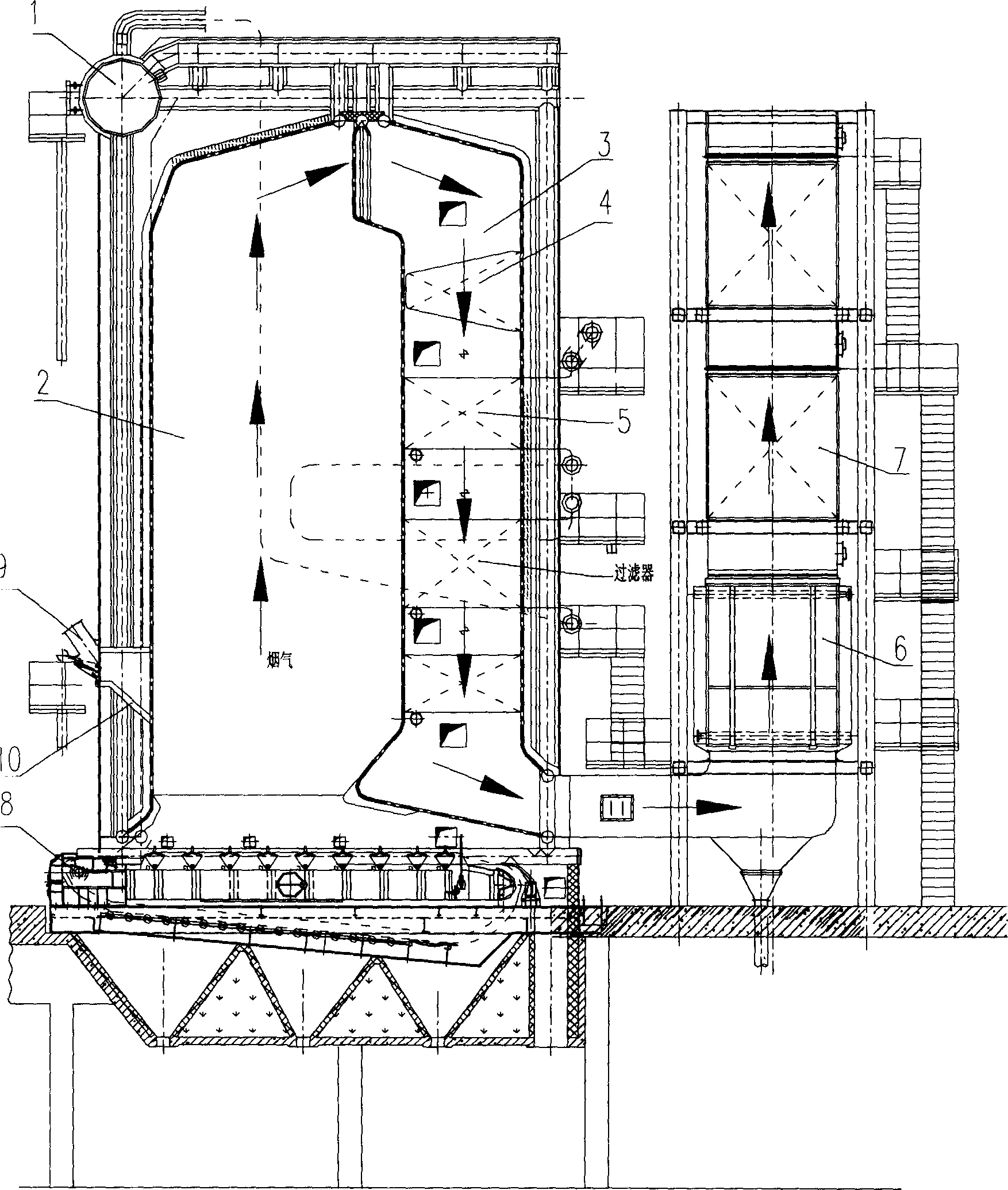

[0011] Such as figure 1 As shown, the boiler used in the present invention adopts a natural circulation form with a drum 1 . Furnace 2 adopts membrane water wall structure. The evaporating heating surface 4 and the superheater 5 are arranged in the flue 3, the evaporating heating surface 4 adopts the layout form of a flag-type heating surface, and the superheater 5 adopts the form of a serpentine tube. There is an economizer 6 and an air preheater 7 in the tail flue, the economizer 6 is in the form of a smooth tube serpentine tube, and the air preheater 7 is in the form of a horizontal bare tube.

[0012] Fire grate 8 adopts scale-type chain grate and equal-pressure air chamber. The primary air of the boiler enters the furnace 2 after being regulated by several groups of small dampers distributed along the length of the grate. and the demands of the embers.

[0013] Each blanking port 9 is angle-adjustable, and below it is a secondary air duct 10. Its function is: (1) use w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com