Preparation of Ag/CNTs/GO compound with sandwich structure

A sandwich structure and sandwich technology, which is applied in the field of Ag/CNTs/GO composites with sandwich structure and their preparation, can solve the problems of limiting wide application, reducing bacteriostatic properties, easy oxidation, etc., achieving simple process and improving dispersibility. , easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

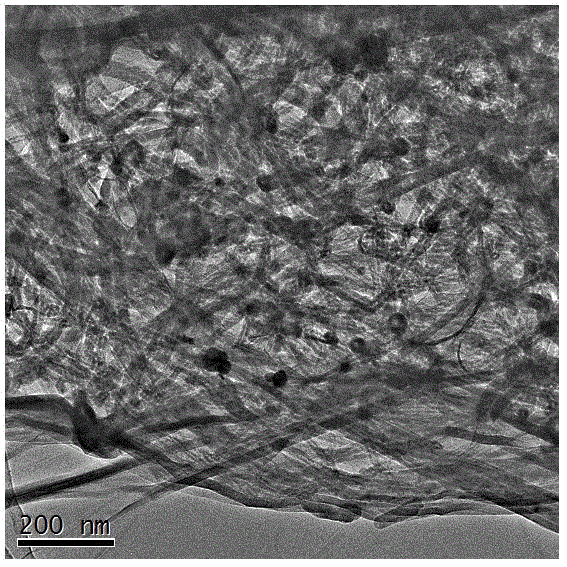

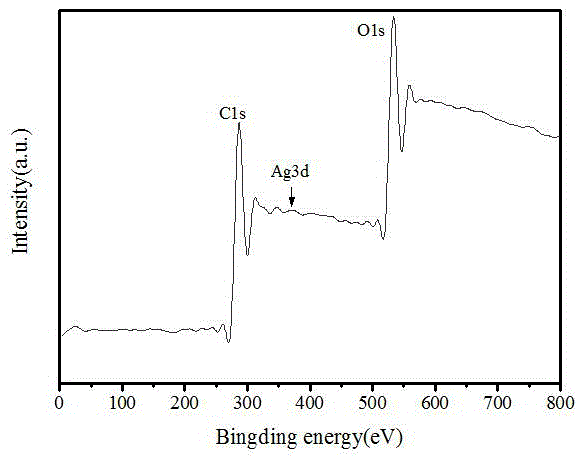

[0027] (1) Prepare 100ml of dopamine hydrochloride (DPA) solution with a concentration of 1mg / ml, add 0.1g of carbon nanotubes (CNTs), and stir magnetically at room temperature for 15 hours for the first time;

[0028] (2) Centrifuge the stirred product, wash it with distilled water, add it to 250ml of graphene oxide (GO) aqueous solution with a concentration of 2mg / ml, and magnetically stir for the second time at room temperature for 1h;

[0029] (3) Add 80ml of 1mM silver nitrate solution and 80ml of 1mM sodium borohydride solution in turn to the solution obtained in (2), and stir at room temperature for 20 hours for the third time;

[0030] (4) The stirred product was centrifuged, washed with water and alcohol for 3 times, and dried in vacuum at room temperature for 24 hours to obtain a silver nanoparticle / carbon nanotube / graphene oxide nanocomposite (Ag / CNTs / GO) with a sandwich structure .

Embodiment 2

[0032] (1) Prepare 100ml of dopamine hydrochloride (DPA) solution with a concentration of 2mg / ml, add 0.3g of carbon nanotubes (CNTs), and stir magnetically at room temperature for 16 hours for the first time;

[0033] (2) Centrifuge the stirred product, wash it with distilled water, add it to 250ml of graphene oxide (GO) aqueous solution with a concentration of 4mg / ml, and magnetically stir for the second time at room temperature for 1.5h;

[0034] (3) Add 80ml of 2mM silver nitrate solution and 80ml of 2mM sodium borohydride solution in turn to the solution obtained in (2), and stir at room temperature for 22 hours for the third time;

[0035] (4) The stirred product was centrifuged, washed with water and alcohol for 3 times, and dried in vacuum at room temperature for 24 hours to obtain a silver nanoparticle / carbon nanotube / graphene oxide nanocomposite (Ag / CNTs / GO) with a sandwich structure .

Embodiment 3

[0037] (1) Prepare 100ml of dopamine hydrochloride (DPA) solution with a concentration of 3mg / ml, add 0.5g of carbon nanotubes (CNTs), and stir magnetically at room temperature for 17h for the first time;

[0038] (2) Centrifuge the stirred product, wash it with distilled water, add it to 250ml of graphene oxide (GO) aqueous solution with a concentration of 6mg / ml, and magnetically stir for the second time at room temperature for 2h;

[0039] (3) Add 80ml of 3mM silver nitrate solution and 80ml of 3mM sodium borohydride solution in turn to the solution obtained in (2), and stir at room temperature for the third time for 24 hours;

[0040] (4) The stirred product was centrifuged, washed with water and alcohol for 3 times, and dried in vacuum at room temperature for 24 hours to obtain a silver nanoparticle / carbon nanotube / graphene oxide nanocomposite (Ag / CNTs / GO) with a sandwich structure .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com