Cloth drying room capable of automatically draining water based on water pressure

A technology for automatic drainage and fabric drying, which is applied in the processing of textile materials, equipment configuration for processing textile materials, textiles and papermaking, etc. Improving drainage and avoiding water backflow in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The following examples are for illustrative purposes only and are not intended to limit the scope of the invention.

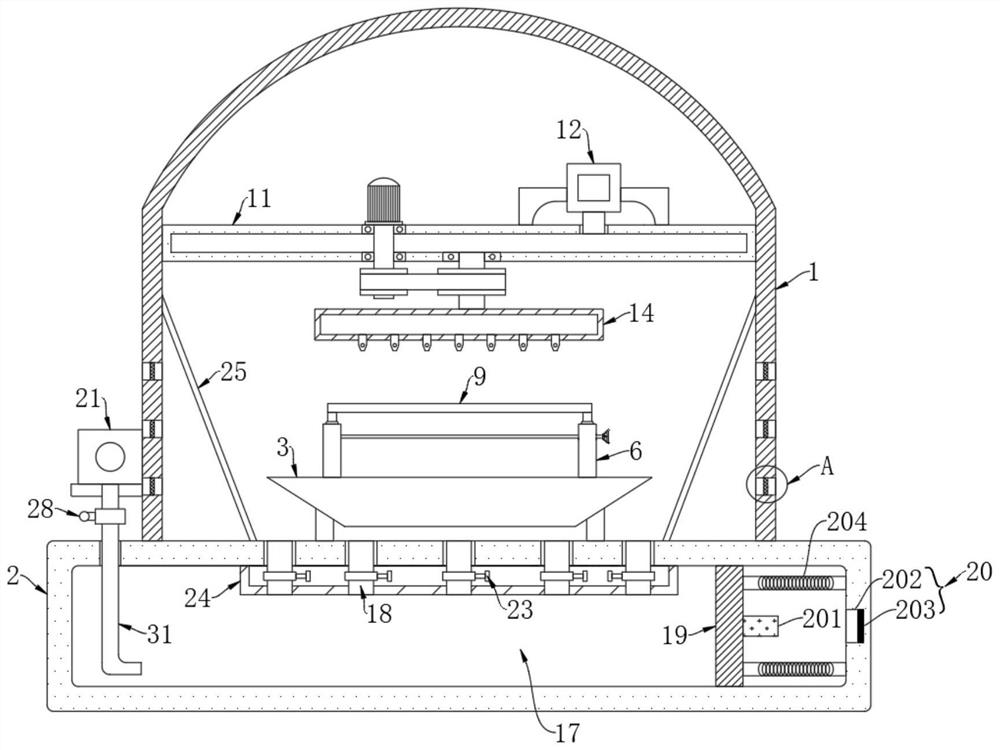

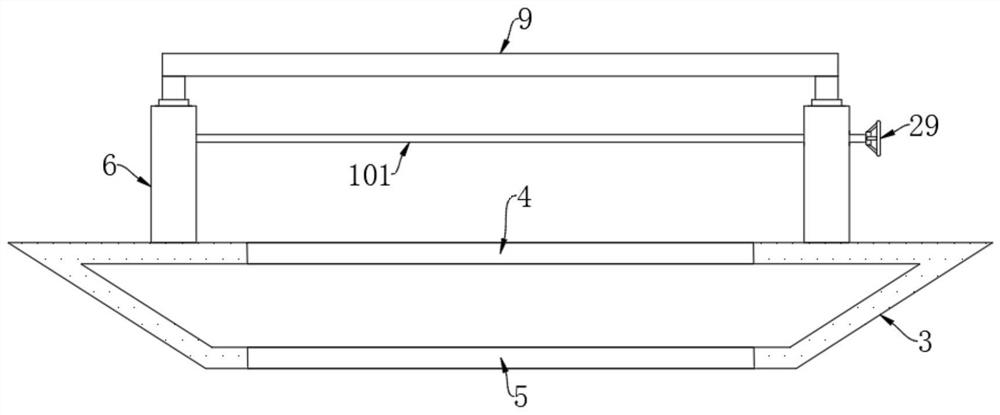

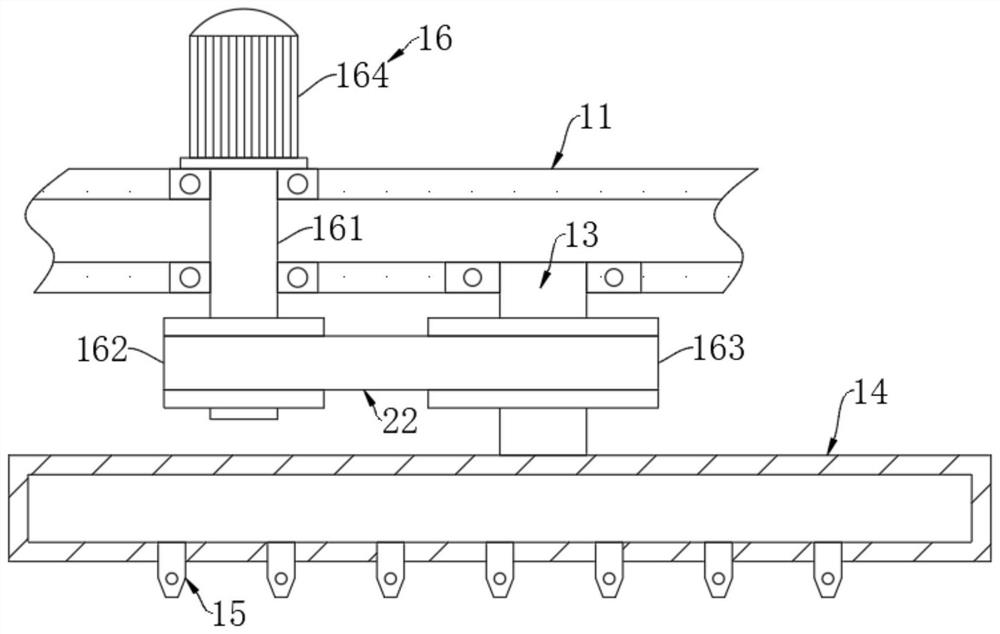

[0028] like Figure 1-5 As shown, a cloth drying room with automatic drainage based on water pressure includes a room body 1, and condensation deflectors 25 are installed on both sides of the room body 1, and the condensation deflectors 25 are made of copper materials. , the room body 1 is provided with a plurality of air holes 26 matched with the condensation deflector 25, and a filter screen 27 is embedded in the air hole 26. The water vapor can be in contact with the condensation guide plate 25, so that the water vapor is converted from a gaseous state to a liquid state, and is discharged through the condensation deflector 25 to the water inlet pipe 18, reducing the possibility of cloth contacting water vapor and improving the drying efficiency of the cloth. The condensation deflector 25 Copper material can be used to improve its own heat dissipation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com