A kind of wrinkled graphene and its controllable preparation method

A graphene and wrinkle technology, applied in the field of graphene with wrinkled structure and its controllable preparation, can solve problems such as randomness and uncontrollability, and achieve the effects of simple equipment, large-scale preparation, and strong controllability and operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

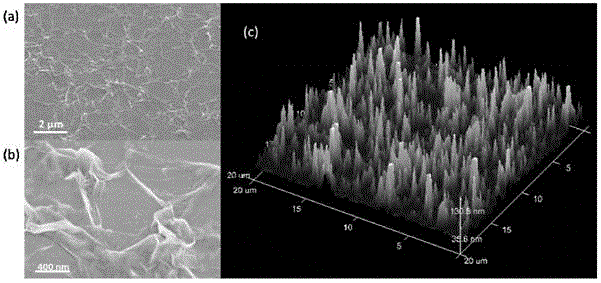

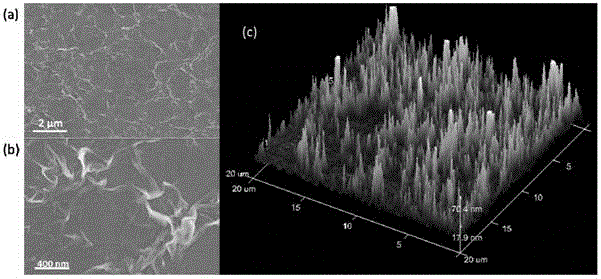

[0034] The invention uses a liquid phase method to controlly prepare graphene with a wrinkled structure. The preparation method of this wrinkled graphene comprises the steps:

[0035] 1) Put the copper-based graphene prepared by chemical vapor deposition on the iron trichloride (FeCl 3 ) on the surface of the solution;

[0036] 2) After 30-60 minutes, the copper substrate is completely etched away by the ferric chloride solution, and the graphene floating on the surface of the ferric chloride solution is transferred to deionized water with a glass slide for cleaning;

[0037] 3) After 3-10 minutes, use a glass slide to transfer the graphene floating on the surface of deionized water to another clean deionized water for cleaning again, and cycle 2-10 times;

[0038] 4) transfer the graphene floating on the surface of deionized water to a petri dish equipped with an organic solution with a glass slide; the volume ratio of organic solvent / deionized water in the organic solution...

Embodiment 1

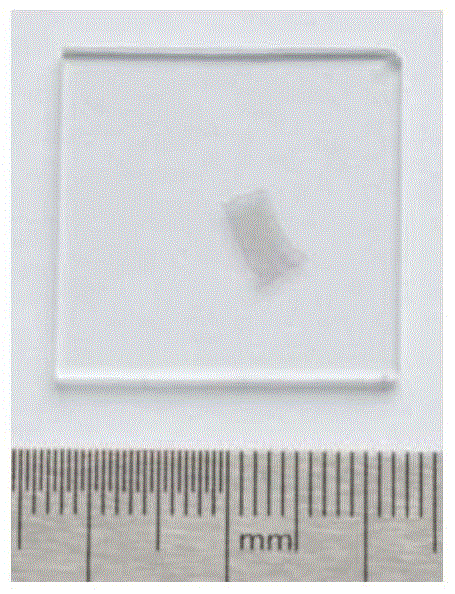

[0044] Prepare a ferric chloride solution with a concentration of 0.5mol / L and pour it into a glass petri dish. Take a piece of copper-based graphene prepared by chemical vapor deposition with a size of 15mm×10mm, place it in the previously prepared ferric chloride solution, and make it float on the surface of the ferric chloride solution. After 30 minutes, it can be observed that part of the copper substrate is etched by the ferric chloride solution; after another 15 minutes, it can be observed that the copper substrate is completely etched by the ferric chloride solution, leaving graphene floating on the ferric chloride solution. on the solution.

[0045] Use a clean glass slide to transfer the graphene floating on the ferric chloride solution to clean deionized water, make it float on the surface of the deionized water for cleaning; after 5min, use a clean glass slide to transfer the graphene floating on the surface of the deionized water The graphene on the deionized wate...

Embodiment 2

[0050] Prepare a ferric chloride solution with a concentration of 0.8mol / L and pour it into a glass petri dish. Take a piece of copper-based graphene prepared by chemical vapor deposition with a size of 15mm×10mm, place it in the previously prepared ferric chloride solution, and make it float on the surface of the ferric chloride solution. After 30 minutes, it can be observed that part of the copper substrate is etched by the ferric chloride solution; after another 15 minutes, it can be observed that the copper substrate is completely etched by the ferric chloride solution, leaving graphene floating on the ferric chloride solution. on the solution.

[0051] Use a clean glass slide to transfer the graphene floating on the ferric chloride solution to clean deionized water, make it float on the surface of the deionized water for cleaning; after 5min, use a clean glass slide to transfer the graphene floating on the surface of the deionized water The graphene on the deionized wate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com