Base plate bearing device

A technology for carrying devices and substrates, which is applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of substrate deformation and falling off, and achieve the effects of low deformation, solving deformation and falling off, and stable and firm fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

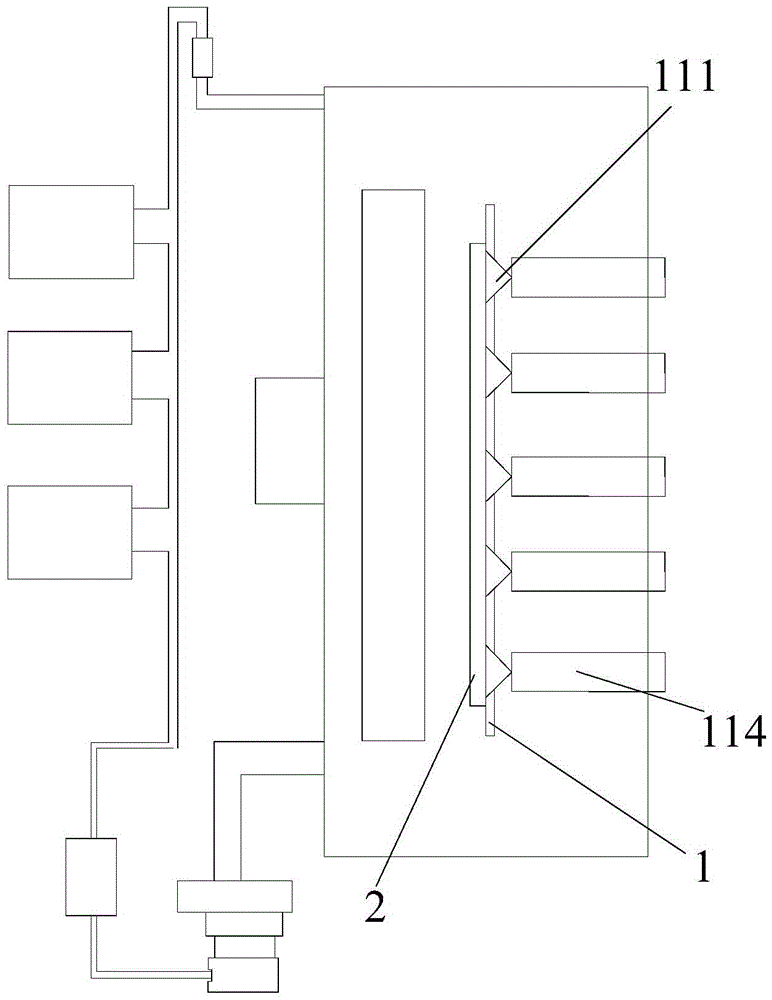

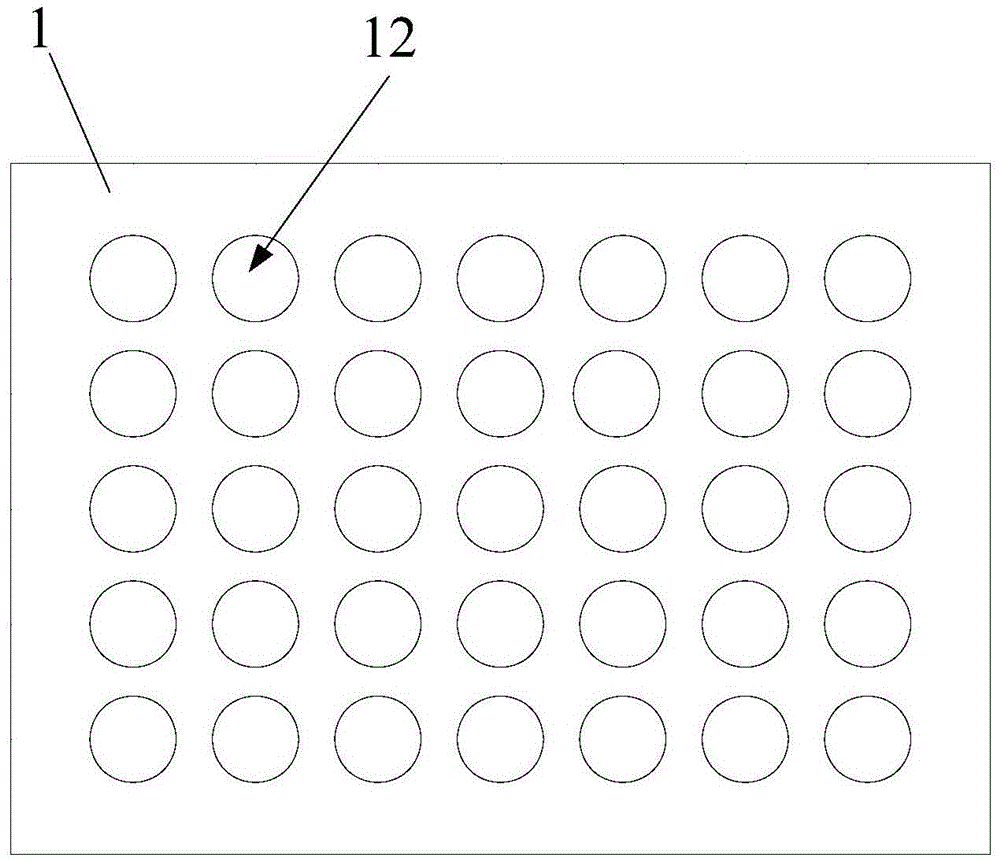

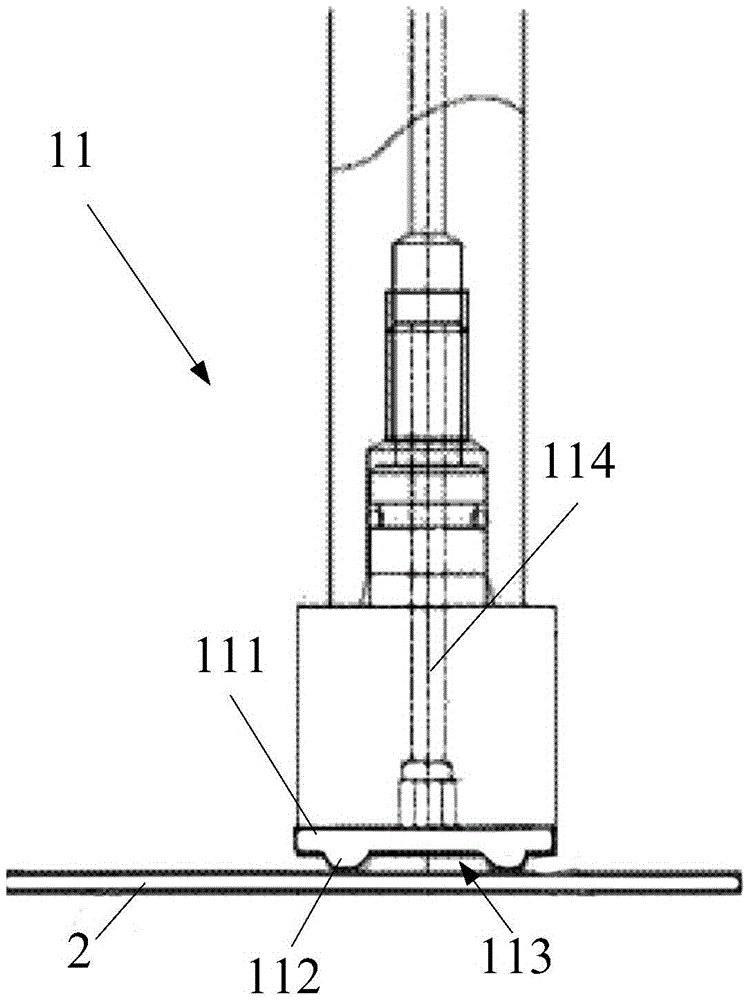

[0037] Such as figure 1 As shown, this embodiment provides a substrate carrying device, including a base 1 and a press-fit adsorption mechanism and a viscous adsorption mechanism arranged on the base 1. The press-fit adsorption mechanism is a vacuum adsorption component. , only the sputtering process is carried out in a vacuum state; for example, the vacuum adsorption can still be used to fix the substrate in the process of transportation, so in this embodiment, the vacuum adsorption assembly is used as the pressing mechanism, and the mechanical arm is used at the beginning. The substrate is placed on the base 1. At this time, the vacuum adsorption component adsorbs and fixes the substrate on the base 1, and at the same time makes the substrate press the viscous adsorption mechanism. At this time, the vacuum adsorption mechanism and the viscous adsorption work at the same time. The substrate is adsorbed; of course, the vacuum adsorption mechanism can also stop working after pr...

Embodiment 2

[0041] Such as Figure 4 As shown, this embodiment provides a substrate carrying device, including a base 1 and a press-fit adsorption mechanism and a viscous adsorption mechanism arranged on the base 1. The press-fit adsorption mechanism is a vacuum adsorption component. In the sputtering process, only the sputtering process is carried out in a vacuum state; for example, the vacuum adsorption can still be used to fix the substrate in the process of transportation, so in this embodiment, the vacuum adsorption assembly is also used as the pressing mechanism. The robotic arm places the substrate on the base 1. At this time, the vacuum adsorption component adsorbs and fixes the substrate on the base 1. At the same time, the substrate is pressed against the viscous adsorption mechanism. At this time, the vacuum adsorption mechanism and the viscous adsorption are simultaneously work together to adsorb the substrate; of course, it is also possible that the vacuum adsorption mechanis...

Embodiment 3

[0045] Such as Figure 5 As shown, the substrate carrying device provided in this embodiment includes a base 1 and a press-fit adsorption mechanism and a viscous adsorption mechanism disposed on the base 1, wherein the viscous adsorption mechanism is a second viscous adsorption mechanism disposed on the base 1. Adsorption layer 14, the press-fit adsorption mechanism is an electrostatic adsorption layer 141 arranged between the base 1 and the second viscous adsorption layer 14; the original vacuum adsorption mechanism is replaced by setting the electrostatic adsorption layer 141, optionally, The electrostatic adsorption layer 141 is made of a metal electrode material; its principle is that the metal electrode is energized, and due to the phenomenon of electrostatic induction, the end close to the metal electrode induces a charge opposite to that of the metal electrode, and is attracted and attached to the metal electrode. ; During use, the electrostatic adsorption layer 141 app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com