A kind of synthetic method for uv-led cured terminal vinyl water-based flame-retardant polyester

A UV-LED and flame-retardant polyester technology, which is applied in the direction of polyester coatings, coatings, fire-resistant coatings, etc., can solve the problems of hydrolysis resistance, coating film performance and poor flame-retardant performance, and achieve low cost and weaken hydrogen Bonding effect, effect of high grafting rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

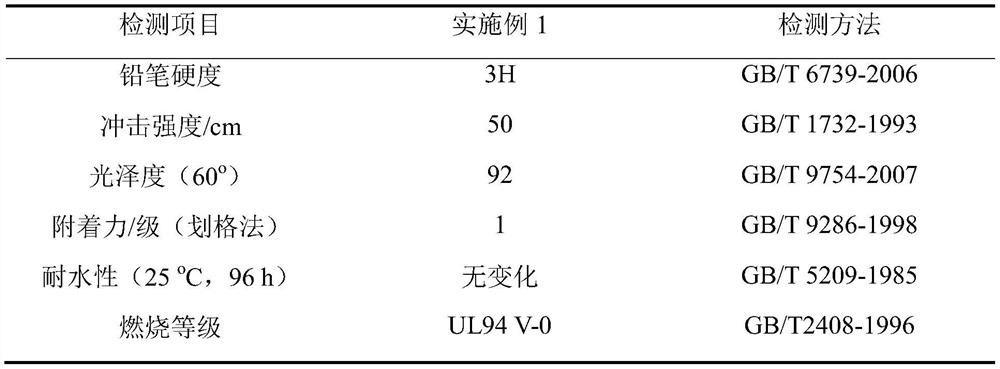

Examples

Embodiment 1

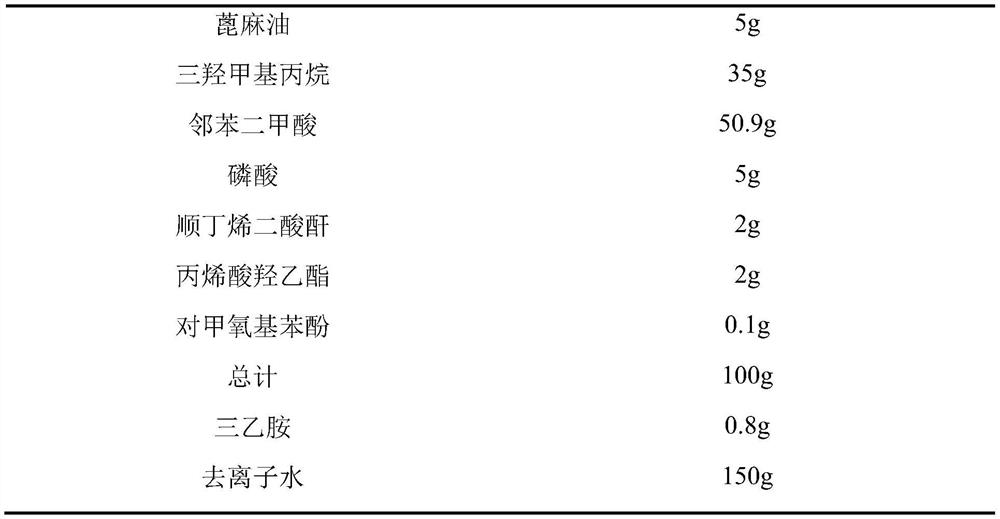

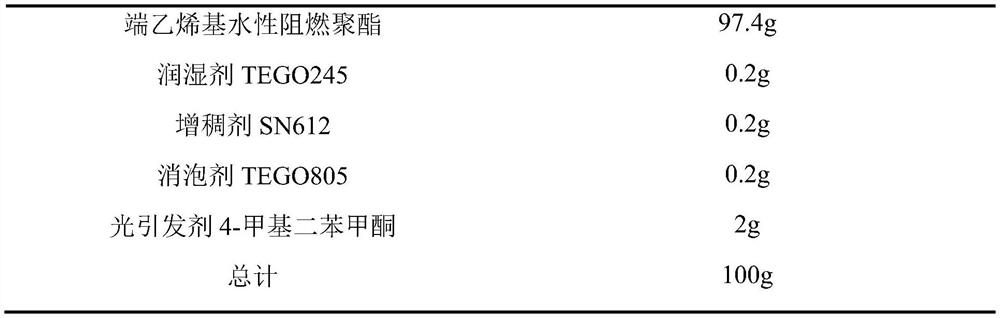

[0031] A kind of synthesis that is used for UV-LED curing terminal vinyl water-based flame retardant polyester, the raw material type and consumption of each component are shown in Table 1 (xylene is used as water-carrying agent):

[0032] Table 1:

[0033]

[0034] Preparation process: in parts by mass, add 50.9g phthalic acid, 35g trimethylolpropane, 5g castor oil and 5g phosphoric acid into the reaction kettle, add xylene as water-carrying agent, and raise the temperature under the protection of nitrogen to 190°C, reflux reaction until the acid value is 9mgKOH / g, extract xylene under reduced pressure; cool down to 130°C, extract water-carrying agent xylene under reduced pressure at a vacuum degree of 0.04-0.1MPa, add 2g maleic anhydride, React for 3 to 5 hours; keep the temperature of the system constant, add 2g of hydroxyethyl acrylate and 0.1g of p-methoxyphenol, react for 4 hours, and obtain an adduct containing a hydrophilic group and a vinyl group; cool down to 50°C...

Embodiment 2

[0045] A kind of synthesis that is used for UV-LED curing terminal vinyl water-based flame-retardant polyester, the raw material type and consumption of each component are shown in Table 4 (xylene is used as water-carrying agent):

[0046] Table 4:

[0047]

[0048]

[0049] Preparation process: in parts by mass, add 50.9g phthalic acid, 5g phosphoric acid, 35g trimethylolpropane and 5g hydroxylated tung oil with multiple double bonds into the reactor, add xylene as water-carrying agent, Under protection, raise the temperature to 190°C, reflux to react to an acid value of 8 mgKOH / g, cool down to 130°C, extract the water-carrying agent xylene under reduced pressure at a vacuum degree of 0.04-0.1 MPa; add 2g of maleic anhydride, and react for 3 hours; Keep the temperature of the system constant, add 2g hydroxyethyl acrylate and 0.1g p-methoxyphenol, react for 4 hours, and obtain an adduct containing hydrophilic groups and vinyl groups; cool down to 50°C, add 0.8g triethyla...

Embodiment 3

[0059] A kind of synthesis that is used for UV-LED curing terminal vinyl water-based flame-retardant polyester, the raw material type and consumption of each component are shown in Table 7 (xylene is used as water-carrying agent):

[0060] Table 7:

[0061]

[0062] Preparation process: In parts by mass, 51.8g of phthalic acid, 6g of phosphoric acid, 30g of pentaerythritol and 6g of castor oil were added to the reaction kettle, xylene was added as a water-carrying agent, and the temperature was raised to 190°C under the protection of nitrogen. Reflux reaction until the acid value is lower than 10mgKOH / g, extract the xylene under reduced pressure; cool down to 130°C, extract the water-carrying agent xylene under reduced pressure at a vacuum degree of 0.04-0.1MPa, add 3g of maleic anhydride, and react for 3- 5h; keep the temperature of the system constant, add 3g hydroxypropyl acrylate and 0.2g p-methoxyphenol, react for 3~5h, and get the adduct containing hydrophilic group a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com