Preparation method of two-dimensional rhenium sulfide-molybdenum sulfide vertical heterostructure

A heterogeneous structure, rhenium sulfide technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effect of low cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

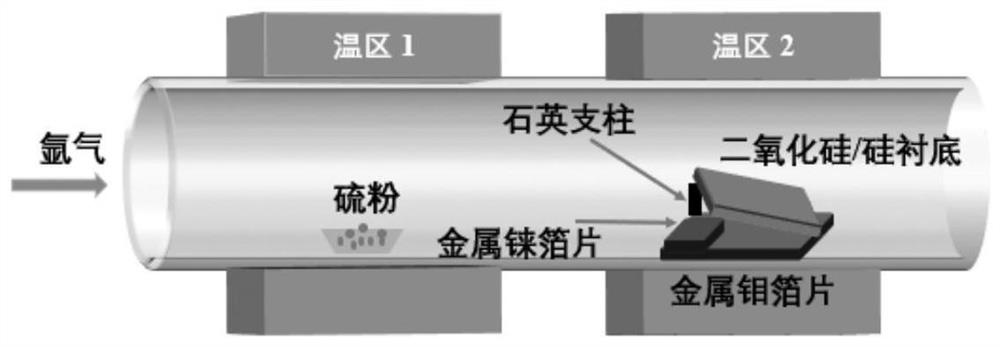

[0031] A preparation method of two-dimensional rhenium sulfide-molybdenum sulfide vertical heterostructure, using chemical vapor deposition method, with Si / SiO 2 For the deposition substrate, metal rhenium foil is used as rhenium source, and metal molybdenum foil is used as molybdenum source, which is prepared by reacting with sulfur source sulfur powder. Its preparation is carried out in a double-temperature zone horizontal tube furnace, and the schematic diagram of the device is shown in figure 1 As shown, wherein, temperature zone 1 is a sulfur source temperature zone, and temperature zone 2 is a deposition temperature zone, specifically including the following preparation steps:

[0032] S1. Choose Si / SiO that does not contain catalyst and seed layer 2 Substrate, the size of the substrate is 1cm×2cm.

[0033] S2. The double-temperature-zone horizontal tube furnace is sequentially set as the sulfur source temperature zone and the deposition temperature zone according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com