Low-temperature direct preparation method of graphene under double-temperature-zone control, and double-temperature-zone tube furnace

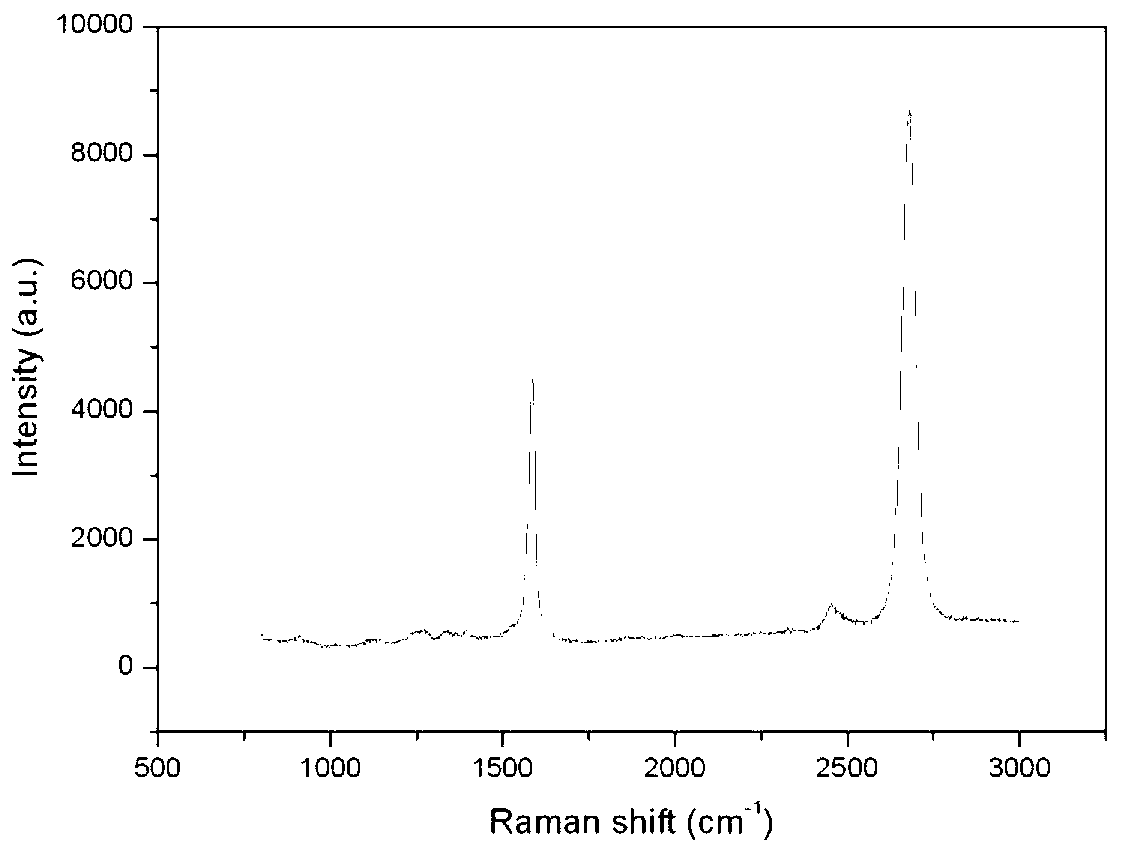

A dual-temperature zone and graphene technology, which is used in the dual-temperature zone to control low temperature to directly prepare graphene. The dual-temperature zone tube furnace field can solve the problem that the carbon source gas cannot be fully cracked, and it is difficult to grow large-area and high-quality graphite. ene thin films, etc., to achieve the effect of large-area growth, simple growth process and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

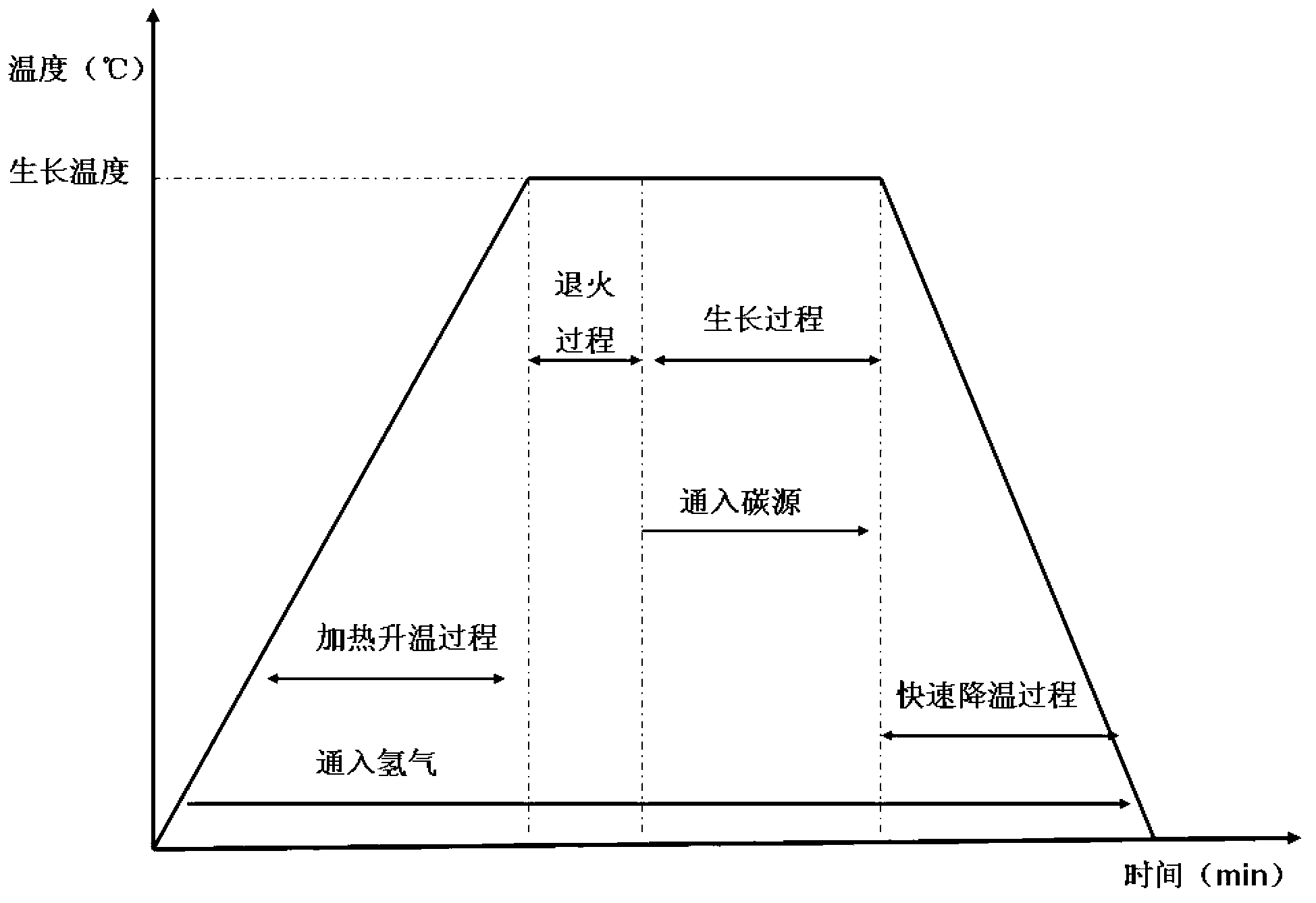

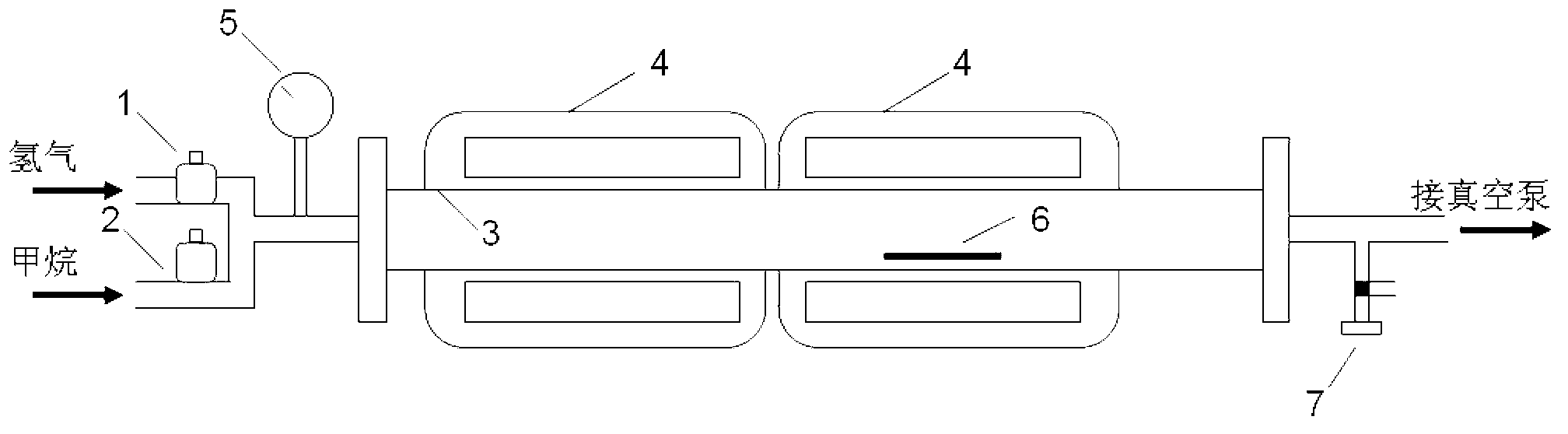

[0048] Through the chemical vapor deposition method, dual temperature zone control directly prepares graphene at low temperature on quartz, such as figure 1 shown, including the following preparation steps

[0049] 1. Take the quartz substrate 6 and place it in the low temperature zone of the quartz tube 3; take the copper foil with a size of 6cm×8cm and place it in the high temperature zone;

[0050] 2. Turn on the vacuum pump to pump the air pressure of the quartz tube 3 to the ultimate vacuum state of 3×10-6 Torr;

[0051] 3. Keep vacuum 3×10 -6 After Torr for 15 minutes (the function of vacuum for 15 minutes is to remove impurities, air, etc. inside the quartz tube to ensure that the reaction chamber is clean), raise the air pressure of the quartz tube 3 to 3×10 -3 Torr;

[0052] 4. Set the hydrogen flow meter 1 to 100 sccm, inject hydrogen into the vacuum chamber;

[0053] 5. Raise the temperature of the temperature zone where the substrate is placed in the dual tempe...

Embodiment 2

[0062] Through the chemical vapor deposition method, dual temperature zone control directly prepares graphene on silicon at low temperature, including the following preparation steps:

[0063] 1. Take the silicon substrate 6 and place it in the quartz tube 3;

[0064] 2. Turn on the vacuum pump to pump the air pressure of the quartz tube 3 to the ultimate vacuum state of 3×10 -6 Torr;

[0065] 3. Keep vacuum 3×10 -6 After Torr for 15 minutes, increase the air pressure of the quartz tube 3 to 3×10 -3 Torr;

[0066] 4. Set the hydrogen flow meter 1 to 100 sccm, inject hydrogen into the vacuum chamber;

[0067] 5. Raise the temperature of the temperature zone where the substrate is placed in the dual temperature zone tube furnace to 450 degrees Celsius, and raise the temperature of the other temperature zone to 1050 degrees Celsius;

[0068] 6. After obtaining the predetermined temperature in the dual-temperature zone tube furnace, anneal at a constant temperature for 20 min...

Embodiment 3

[0075] Through the chemical vapor deposition method, dual temperature zone control directly prepares graphene at low temperature on the glass sheet, including the following preparation steps:

[0076] 1. Take the glass sheet substrate 6 and place it in the quartz tube 3;

[0077] 2. Turn on the vacuum pump to pump the air pressure of the quartz tube 3 to the ultimate vacuum state of 3×10 -6 Torr;

[0078] 3. Keep vacuum 3×10 -6 After Torr for 15 minutes, increase the air pressure of the quartz tube 3 to 3×10 -3 Torr;

[0079] 4. Set the hydrogen flow meter 1 to 100 sccm, inject hydrogen into the vacuum chamber;

[0080] 5. Raise the temperature of the temperature zone where the substrate is placed in the dual temperature zone tube furnace to 450 degrees Celsius, and raise the temperature of the other temperature zone to 1050 degrees Celsius;

[0081] 6. After obtaining the predetermined temperature in the dual-temperature zone tube furnace, anneal at a constant temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com