Preparation method and application of monodisperse hydrothermal carbon spheres

A hydrothermal carbon, monodisperse technology, applied in the field of materials, can solve problems such as difficult to achieve industrialization and green environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Prepare a glucose solution with a concentration of 0.25M (V 水 :V 乙醇 =30:1);

[0042] 2) Take 60 mL of the glucose solution with the above concentration, put it into an autoclave, seal it, heat it to 180°C for 8 hours, and cool it down to room temperature naturally after the reaction to obtain a glucose hydrothermal carbon sphere solution.

[0043] 3) The above solution is separated by gradient centrifugation at 25,000r / min to 3,000r / min, and repeatedly ultrasonically dispersed with absolute ethanol and deionized water, and centrifugally washed until the supernatant is clear, transparent and colorless.

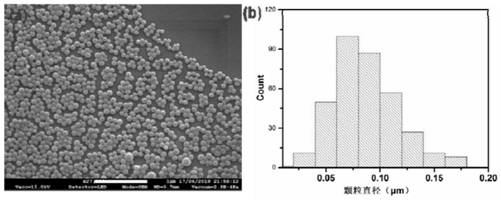

[0044] Conclusion: if figure 1 As shown, through gradient centrifugation, the particle size distribution range of carbon spheres with a size of 0.45-0.71 μm can be obtained, the statistical average size is 0.60 μm, and the surface of carbon spheres is relatively rough.

Embodiment 2

[0046] 1) Prepare a glucose solution with a concentration of 0.25M (V 水 :V 乙醇 =30:1);

[0047] 2) Take 60 mL of the glucose solution with the above concentration, put it into an autoclave, seal it, heat it to 180°C for 8 hours, and cool it down to room temperature naturally after the reaction to obtain a glucose hydrothermal carbon sphere solution.

[0048] 3) The above solution was separated by gradient centrifugation at 6000r / min, and repeatedly ultrasonically dispersed with absolute ethanol and deionized water, and centrifugally washed until the supernatant was clear, transparent and colorless.

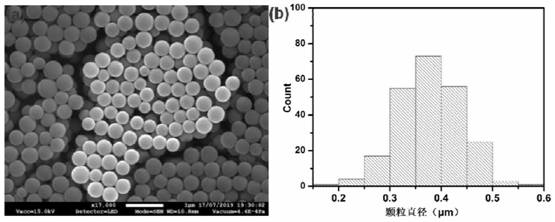

[0049] Conclusion: if figure 2 As shown, the particle size distribution range of carbon spheres with a size of 0.2-0.6 μm can be obtained, the statistical average size is 0.33 μm, and the surface of carbon spheres is relatively rough. Compared with Example 1, it can be seen that hydrothermal carbon spheres of different sizes can be separated by controlling the centrifugation ra...

Embodiment 3

[0051] 1) Prepare a glucose solution with a concentration of 0.25M (V 水 :V 乙醇 =15:1);

[0052] 2) Take 60 mL of the glucose solution with the above concentration, put it into an autoclave, seal it, heat it to 180°C for 8 hours, and cool it down to room temperature naturally after the reaction to obtain a glucose hydrothermal carbon sphere solution.

[0053] 3) The above solution was separated by gradient centrifugation at 6000r / min, and repeatedly ultrasonically dispersed with absolute ethanol and deionized water, and centrifugally washed until the supernatant was clear, transparent and colorless.

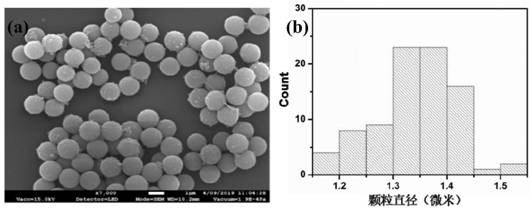

[0054] Conclusion: if image 3 As shown, the particle size distribution range of carbon spheres with a size of 0.15-0.5 μm can be obtained, the statistical average size is 0.38 μm, and the surface of carbon spheres is relatively rough. Compared with Example 2, it can be found that the size and particle size distribution of hydrothermal carbon spheres can be changed when only the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com