Manufacturing method of micro lens array mold

A technology of a microlens array and a manufacturing method, which is applied in the direction of the photoplate-making process of the lens and the pattern surface, and the coating equipment of the photo-plate-making process, which can solve the problems of high requirements and easy formation of undercuts on the concave surface, and achieve low cost and good quality. Surface smoothness, increase the effect of closeness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] The present invention will be described in further detail below with reference to the drawings and specific embodiments.

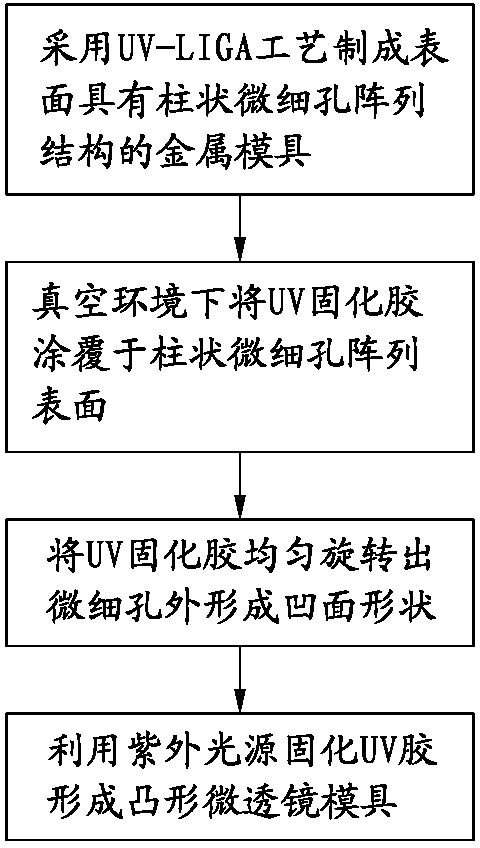

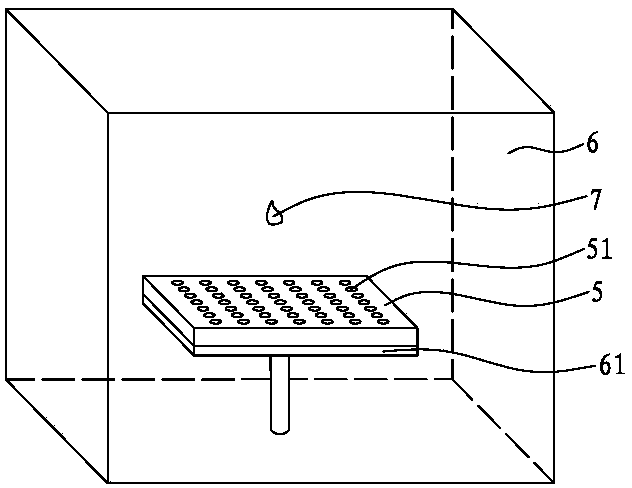

[0060] The invention discloses a method for manufacturing a micro lens array mold, such as figure 1 As shown, including the following steps:

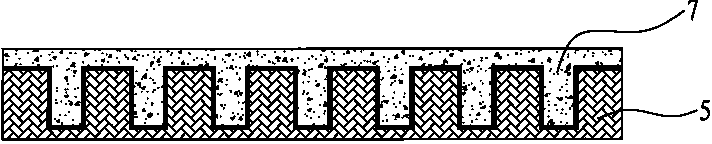

[0061] Step 1: Use the UV-LIGA process to make a metal nickel mold with a columnar micro-hole array structure on the surface;

[0062] 1. Fabrication of SU8 glue micro-pillar array.

[0063] (1) Cleaning and baking of silicon substrate;

[0064] The following cleaning methods can be used: First, use concentrated sulfuric acid to clean: put the silicon wafer (silicon substrate) into a beaker, pour an appropriate amount of concentrated sulfuric acid, and place it on the electric stove in the exhaust cabinet, turn on the exhaust fan, and heat for 10-15 minutes. After the concentrated sulfuric acid smokes, unplug the plug; after cooling for half an hour, pour the concentrated sulfuric acid into the waste liquid bottle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com