Method for recovering rhodium from homogeneous waste catalyst containing rhodium

A technology of waste catalyst and catalyst amount, applied in the direction of improving process efficiency, can solve the problems of low overall recovery rate, serious environmental pollution, low rhodium content concentration, etc., and achieve the effect of improving recovery rate, reducing dispersion and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

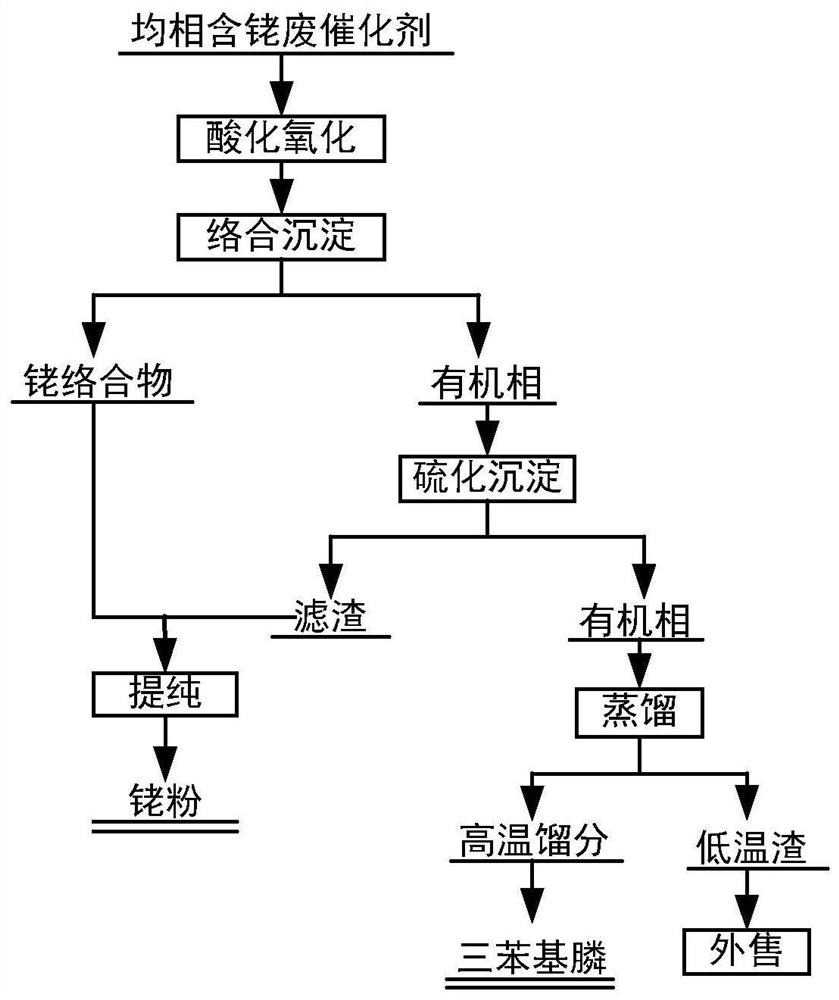

[0028] A method for recovering rhodium from a homogeneous waste catalyst containing rhodium, such as figure 1 As shown, the method includes the following steps:

[0029] Step 1: Take a certain amount of spent catalyst, and at room temperature, first add 5% hydrochloric acid with the amount of spent catalyst to the spent catalyst, and then add 3% hydrogen peroxide with the amount of spent catalyst, heat to 90°C, and keep warm and stir to react 2h;

[0030] Step 2: After step 1 is completed, add a mixed solution of 4% oxalic acid and 3% formic acid with the amount of spent catalyst, continue to keep the temperature and stir for 2.5 hours, and then cool and filter after the completion of the temperature.

[0031] Step 3: Heat the filtrate obtained from step 2 with stirring to 90°C, and add 10% Na with a mass fraction dropwise 2 S solution, add Na 2 The amount of S is 2% of the amount of spent catalyst, keep it for 3 hours, and then cool and filter after keeping it warm;

[0032] 2Rh 3+ +...

Embodiment 2

[0039] A method for recovering rhodium from a homogeneous waste catalyst containing rhodium, such as figure 1 As shown, the method includes the following steps:

[0040] Step 1: Take a certain amount of spent catalyst, at room temperature, first add 20% sulfuric acid of the spent catalyst, and then add 30% hydrogen peroxide of the spent catalyst to the spent catalyst, heat to 70°C, and keep warm and stir to react 0.5h;

[0041] Step 2: Step 1 is finished with heat preservation, then add the mixed solution of 25% oxalic acid and 18% formic acid with the amount of spent catalyst, continue to keep the temperature and stirring reaction for 1h, and then cool and filter after the completion of keeping warm;

[0042] Step 3: The filtrate obtained by filtering in step 2 is heated to 60℃ with stirring, and 30% Na with a mass fraction is added dropwise 2 S solution, add Na 2 The amount of S is 15% of the amount of spent catalyst, keep it for 1 hour, and then cool and filter after keeping it wa...

Embodiment 3

[0047] A method for recovering rhodium from a homogeneous waste catalyst containing rhodium, such as figure 1 As shown, the method includes the following steps:

[0048] Step 1: Take a certain amount of spent catalyst. At room temperature, first add 15% hydrochloric acid with the amount of spent catalyst to the spent catalyst, and then add 16% sodium chlorate with the amount of spent catalyst, heat to 80°C, and heat to react with stirring. 1h;

[0049] Step 2: After step 1 is completed, add a mixed solution of 15% oxalic acid and 10% formic acid with the amount of spent catalyst, continue the temperature keeping and stirring reaction for 2 hours, and then cool and filter after the completion of the keeping warm;

[0050] Step 3: The filtrate obtained by filtering in step 2 is heated to 75°C with stirring, and 20% Na is added dropwise. 2 S solution, add Na 2 The amount of S is 9% of the amount of spent catalyst, keep it for 2h, cool and filter after keeping it warm;

[0051] Step 4: Co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com