Heat-resistant and acid-alkali-resistant organic silica gel

An organic silica gel, acid and alkali resistance technology, used in adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problem that acid and alkali resistance and high temperature resistance are not ideal, cannot be used in thermal power plants, heat Insufficient stability and acid and alkali resistance to achieve the effect of improving thermal stability and acid and alkali resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

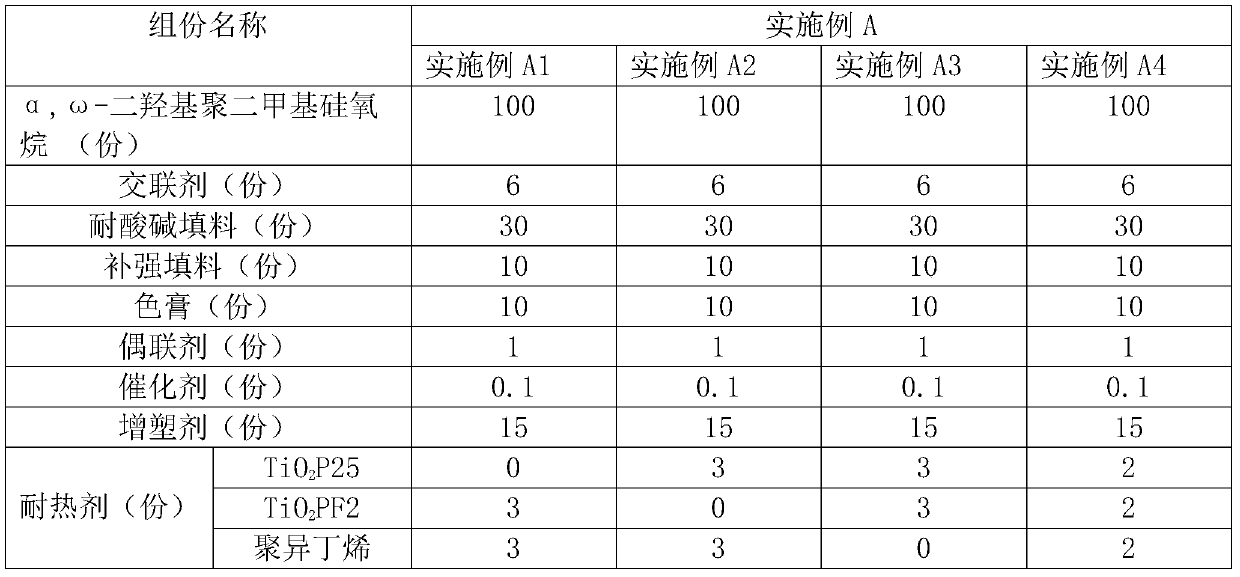

Embodiment A

[0044] Add α,ω-dihydroxy polydimethylsiloxane, color paste, heat-resistant agent and plasticizer to the planetary mixer at room temperature, stir under vacuum for 20 minutes, then add crosslinking agent, stir under vacuum for 20 minutes Minutes; add baked acid and alkali-resistant filler and grilled reinforcing filler in stages, and stir in vacuum for 20 minutes; then add coupling agent and catalyst and stir in vacuum for 25 minutes to obtain organic silica gel.

[0045]The cross-linking agent is a 1:1 combination of methyl tributylketoxime silane and methyl triacetone oximino silane; the acid and alkali resistant filler is ultrafine precipitated barium sulfate; the reinforcing filler has a specific surface area of not less than 150m 2 / g of hydrophobic fumed silica; the color paste is titanium dioxide series color paste; the coupling agent is γ-aminopropyltriethoxysilane, N-β-(aminoethyl)-γ-aminopropyltrimethoxy base silane and γ-aminopropyltrimethoxysilane in a 1:2:1 combi...

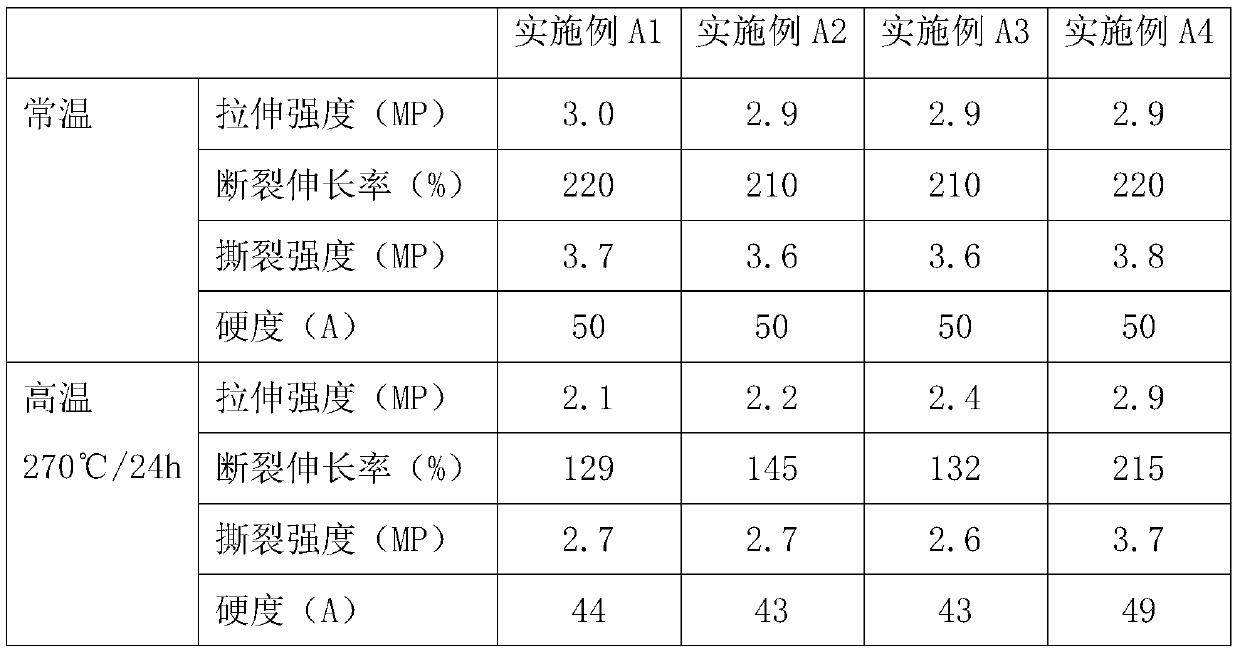

Embodiment A4

[0055] And embodiment A4, has used TiO 2 P25, TiO 2 The combination of PF2 and polyisobutylene, after 24h at 270°C, the tensile strength performance remained unchanged at 2.9MP; the elongation at break decreased from 220% to 215%, and only decreased by less than 5%; the tear strength decreased from 3.8MP Drop to 3.7MP, only drop 0.1MP; Hardness drops to 49A from 50A, only drop 1A; Through embodiment A4 alone and embodiment A1, embodiment A2 and embodiment A3 contrast can draw a conclusion, in this formulation system, and Use TiO 2 P25, TiO 2 Both PF2 and polyisobutylene cannot obtain thermal stability, while using TiO 2 P25, TiO 2 The combination of PF2 and polyisobutylene can greatly improve thermal stability, and can withstand 270°C environment for 24 hours without drastic change in performance.

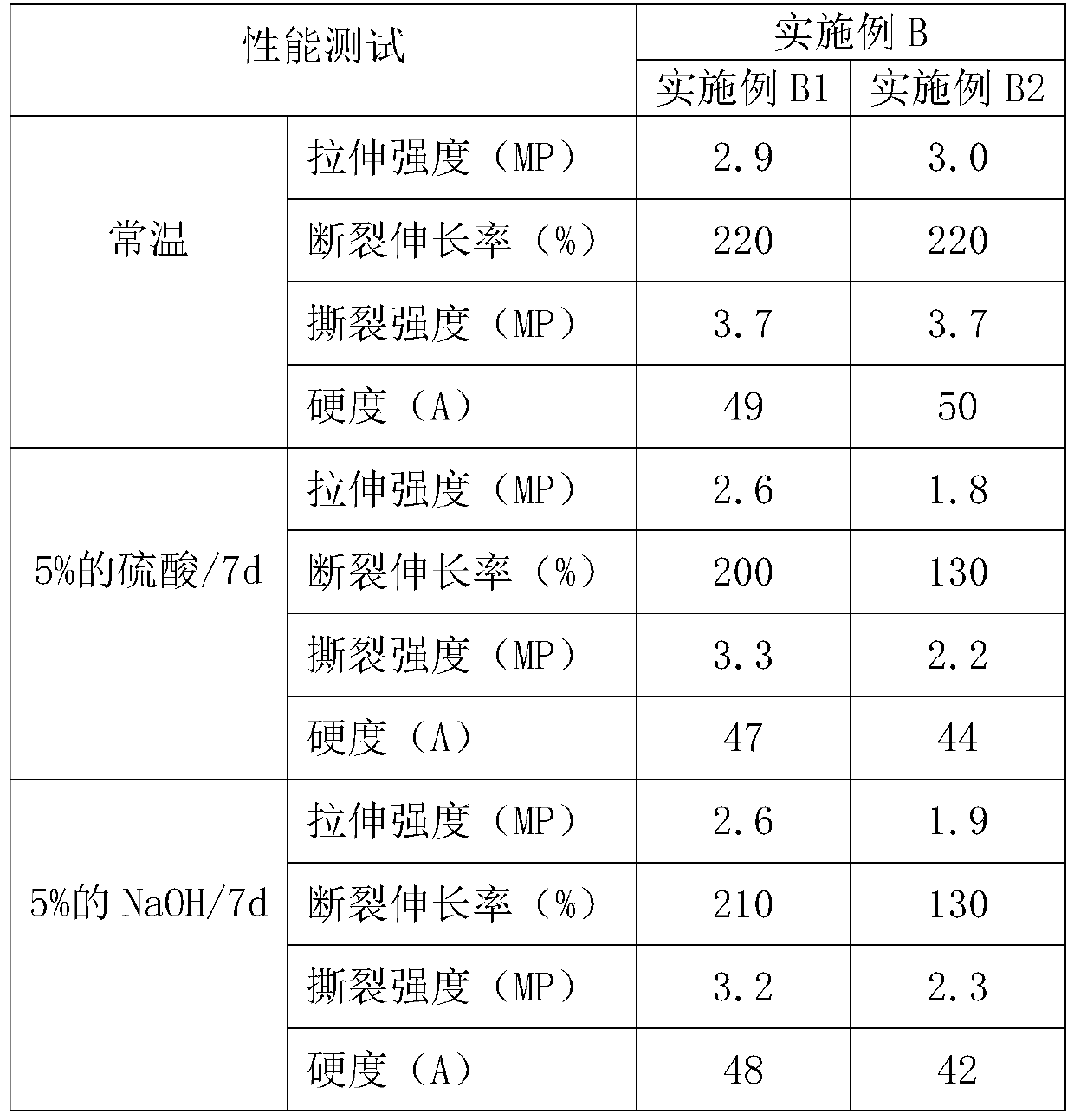

Embodiment B1

[0058] Add 100 parts of α, ω-dihydroxypolydimethylsiloxane, 10 parts of color paste, 9 parts of heat-resistant agent and 15 parts of plasticizer to the planetary mixer at room temperature, After stirring for 10 minutes under vacuum conditions, add 6 parts of cross-linking agent, and stir for 10 minutes under vacuum; add 30 parts of baked acid and alkali-resistant fillers and 10 parts of grilled reinforcing fillers, and stir for 10 minutes under vacuum; then add 1 part of coupling agent and 0.1 part of catalyst were stirred in vacuum for 15 minutes to obtain organic silica gel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com