Two-component impervious environment-friendly material for pipeline and preparation method thereof

An environmentally friendly material and two-component technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of product quality, decline, and impact of production shutdowns in production enterprises, and achieve improved application performance, high elongation, and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

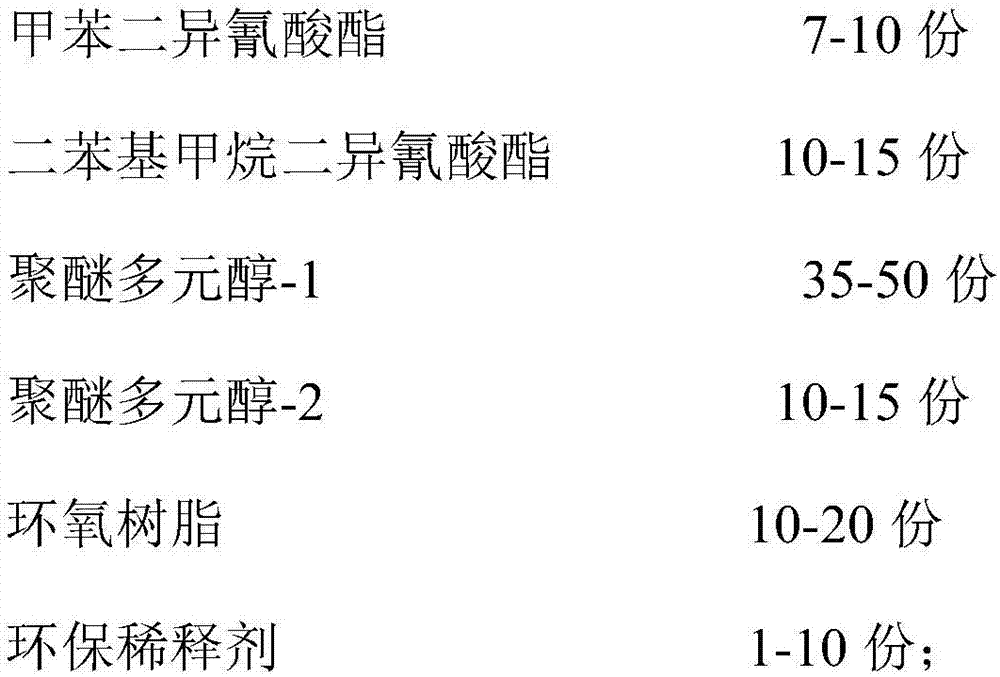

[0037] A two-component anti-seepage environmental protection material for pipelines, which is formed by mixing components A and B at a weight ratio of 1:1, wherein component A is composed of the following parts by weight:

[0038]

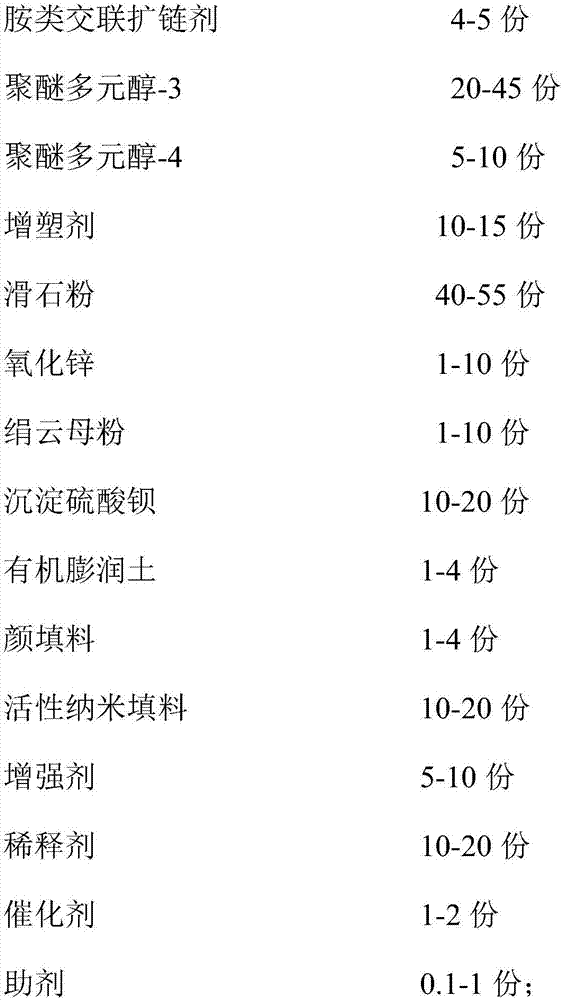

[0039] Component B consists of the following parts by weight:

[0040]

[0041] The active nanometer filler is mixed with nanometer calcium carbonate powder into ester or ketone solvent containing coupling agent and mixed thoroughly, and then the solvent is removed by drying equipment for subsequent use.

[0042] The polyether polyol-1 is a type of polyether polyol with a functionality of 2 and a molecular weight of 1000-6000; the polyether polyol-2 is a type of polyether polyol with a functionality of 2-3 and a molecular weight of 1000-3000; Polyether polyol-3 is a type of polyether polyol with a functionality of 2 and a molecular weight of 1000-3000; polyether polyol-4 is a type of polyether polyol with a functionality of 2 and a molecular ...

Embodiment 2

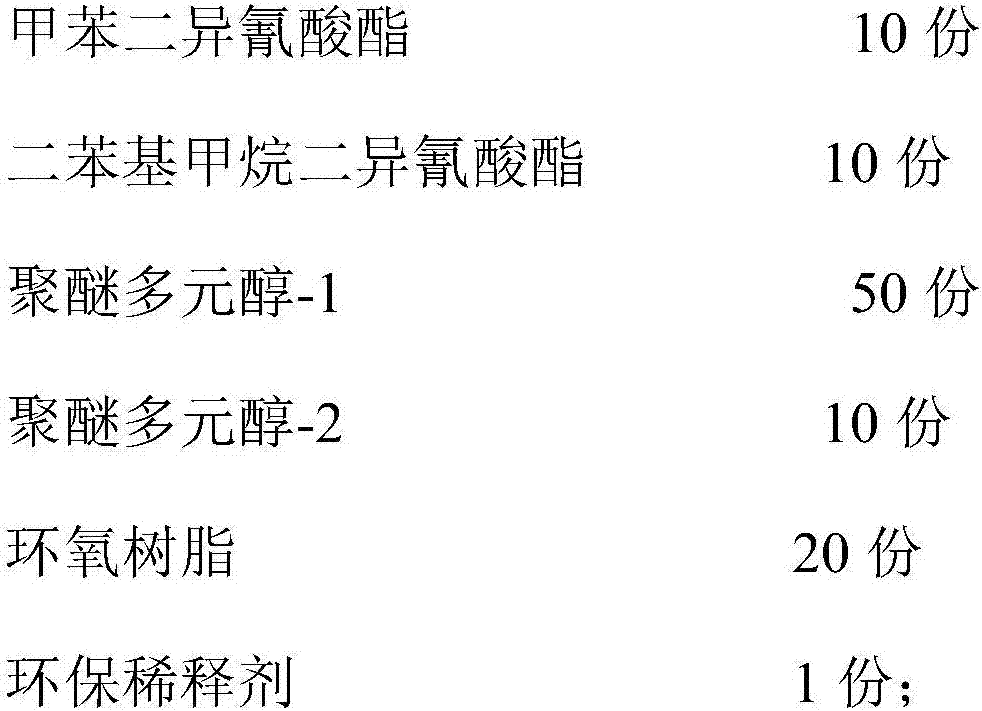

[0050] A two-component anti-seepage environmental protection material for pipelines, which is formed by mixing components A and B at a weight ratio of 1:2, wherein component A is composed of the following parts by weight:

[0051]

[0052]

[0053] Component B consists of the following parts by weight:

[0054]

[0055] The active nanometer filler is mixed with nanometer calcium carbonate powder into ester or ketone solvent containing coupling agent and mixed thoroughly, and then the solvent is removed by drying equipment for subsequent use.

[0056]The polyether polyol-1 is a type of polyether polyol with a functionality of 2 and a molecular weight of 1000-6000; the polyether polyol-2 is a type of polyether polyol with a functionality of 2-3 and a molecular weight of 1000-3000; Polyether polyol-3 is a type of polyether polyol with a functionality of 2 and a molecular weight of 1000-3000; polyether polyol-4 is a type of polyether polyol with a functionality of 2 and a...

Embodiment 3

[0064] A two-component anti-seepage environmental protection material for pipelines, which is formed by mixing components A and B at a weight ratio of 1:3, wherein component A is composed of the following parts by weight:

[0065]

[0066] Component B consists of the following parts by weight:

[0067]

[0068]

[0069] The active nanometer filler is mixed with nanometer calcium carbonate powder into ester or ketone solvent containing coupling agent and mixed thoroughly, and then the solvent is removed by drying equipment for subsequent use.

[0070] The polyether polyol-1 is a type of polyether polyol with a functionality of 2 and a molecular weight of 1000-6000; the polyether polyol-2 is a type of polyether polyol with a functionality of 2-3 and a molecular weight of 1000-3000; Polyether polyol-3 is a type of polyether polyol with a functionality of 2 and a molecular weight of 1000-3000; polyether polyol-4 is a type of polyether polyol with a functionality of 2 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com