Pure-copper-imitated anti-corrosion powder coating

A powder coating, red copper technology, applied in powder coatings, anti-corrosion coatings, polyester coatings, etc., can solve problems such as difficult to achieve metal effects, and achieve excellent anti-corrosion performance and good alkali resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

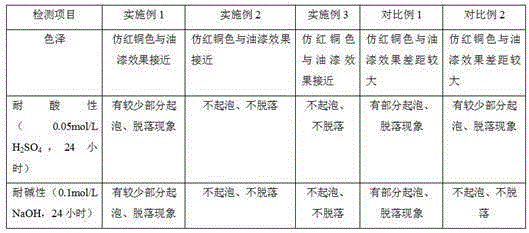

Examples

Embodiment 1

[0017] A kind of imitation red copper anticorrosion powder coating, by weight, the raw material is composed of: 40 parts of epoxy resin, 44 parts of carboxyl-terminated saturated polyester resin, 1 part of leveling agent, 13 parts of precipitated barium sulfate, 0.5 part of benzoin, 1.5 parts of polyethylene wax.

[0018] Put each component into a high-speed mixer in order to mix evenly, and then extrude through a twin-screw extruder, tablet, cool, crush, and sieve to make a powder coating base powder, and then mix 92 parts of base powder, 4 parts of pearl powder, and 4 A portion of red gold powder was put into a bonding machine, passed through a protective gas, and bonded at 65° C. at 600 rpm for 4 minutes to obtain a bonding powder.

Embodiment 2

[0020] A kind of imitation red copper anticorrosion powder coating, by weight, the raw material is composed of: 44.4 parts of epoxy resin, 43 parts of carboxyl-terminated saturated polyester resin, 1.2 parts of leveling agent, 10 parts of precipitated barium sulfate, 0.6 part of benzoin, 1.8 parts of polyethylene wax, 5 parts of nickel slag powder;

[0021] A method for preparing the above-mentioned imitation red copper anti-corrosion powder coating, each component is put into a high-speed mixer in turn to mix uniformly, and then extruded through a twin-screw extruder, pressed into tablets, cooled, crushed, and sieved to make a powder coating Base powder, then put 92 parts of base powder, 5 parts of pearl powder, 3 parts of red gold powder, and 5 parts of nickel slag powder into the bonding machine, pass in protective gas, and bond at 70°C and 500rpm for 3min to obtain bonding powder.

Embodiment 3

[0023] A kind of imitation red copper anticorrosion powder coating, by weight, the raw material is composed of: 40 parts of epoxy resin, 37.1 parts of carboxyl-terminated saturated polyester resin, 1.1 parts of leveling agent, 19 parts of precipitated barium sulfate, 0.8 part of benzoin, 2 parts of polyethylene wax, 6 parts of nickel slag powder;

[0024] A method for preparing the above-mentioned imitation red copper anti-corrosion powder coating, each component is put into a high-speed mixer in turn to mix uniformly, and then extruded through a twin-screw extruder, pressed into tablets, cooled, crushed, and sieved to make a powder coating For base powder, put 91 parts of base powder, 5 parts of pearl powder, 4 parts of red gold powder, and 6 parts of nickel slag powder into the bonding machine, pass in protective gas, and bond at 60°C and 900 rpm for 6 minutes to obtain bonding powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com