Wet and dry joint-coating primer for heat shrinkable tape and manufacturing method thereof

A heat-shrinkable tape, wet and dry dual-use technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc. Function is not prominent and other problems, to achieve the effect of excellent storage stability, excellent constructability, excellent corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

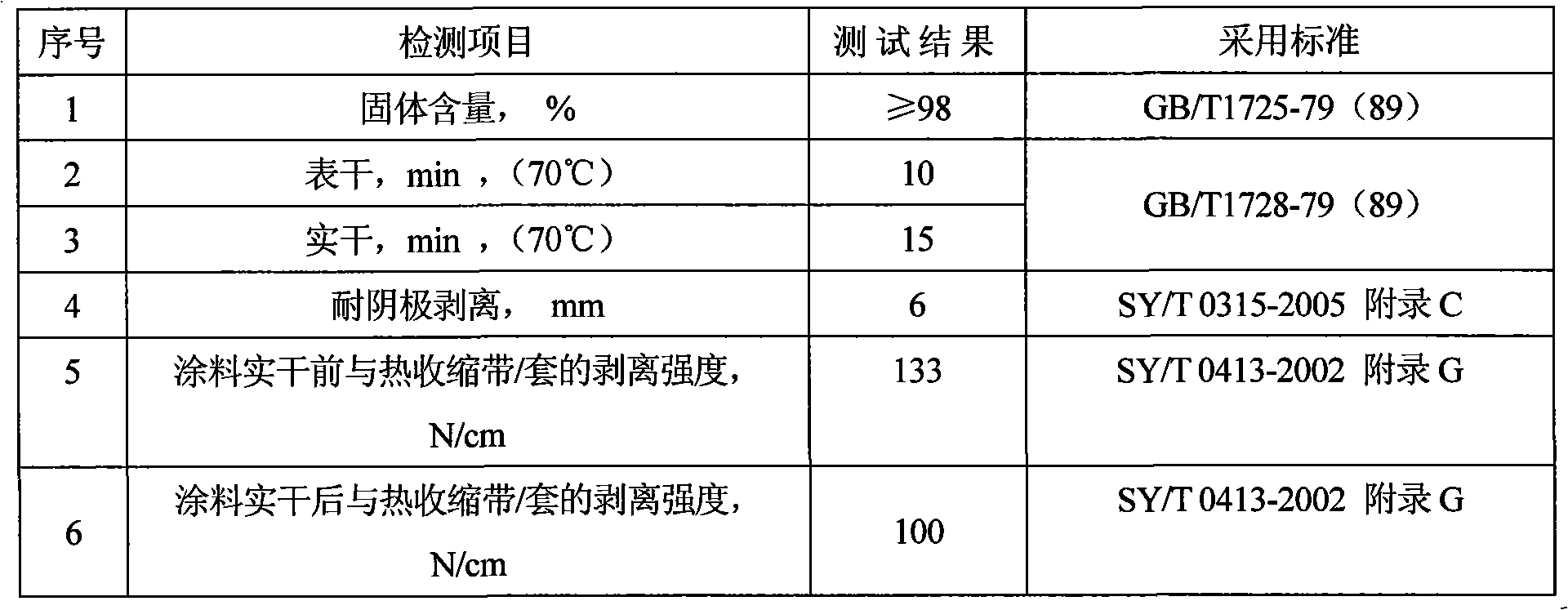

Examples

Embodiment 1

[0014] The invention discloses a manufacturing method of a heat-shrinkable sealing primer that can be used in both dry and wet conditions. In a stainless steel bucket, add 0.7 parts of bisphenol A epoxy resin, 0.3 parts of novolac epoxy resin, 0.06 parts of long-chain polyamine amide and polar acidic ester sodium salt, 0.015 parts of high molecular weight polycarboxylic acid Amine derivative solution, 0.012 parts of polyether-modified polydimethylsiloxane solution, 0.015 parts of alkyl-aryl modified dimethylsiloxane solution, heated and controlled at 25°C, Mix and stir at high speed, add 0.03 parts of fumed silica powder, 0.005 parts of carbon black, 0.12 parts of precipitated barium sulfate, 0.15 parts of mica powder, and 0.12 parts of talc powder while stirring, and stir at high speed for 0.25h Finally, use a sand mill to grind for 0.5-1h, then add 0.03 parts of γ-aminopropyltriethoxysilane solution, 0.15 parts of glass flakes and 0.04 parts of activated polyamide wax while ...

Embodiment 2

[0019] Add 0.01 part of long-chain polyamine amide and polar acidic ester sodium salt, 0.005 part of derivatization of high molecular weight polycarboxylate amine in 0.5 part of bisphenol A epoxy resin, 0.2 part of novolak epoxy resin by weight solution, 0.005 parts of polyether-modified polydimethylsiloxane solution, and 0.005 parts of alkyl-aryl-modified dimethylsiloxane solution, heated and controlled the temperature at 25 ° C, mixed, Stir at high speed, add 0.01 part of fumed silica powder, 0.002 part of carbon black, 0.05 part of precipitated barium sulfate, 0.05 part of mica powder, 0.05 part of talcum powder under the condition of stirring, stir at high speed for 0.25h and use sand Grind in a mill for 0.5 to 1 hour, then add 0.01 part of γ-aminopropyltriethoxysilane solution, 0.1 part of glass flakes and 0.01 part of activated polyamide wax under stirring, and stir at high speed for 0.25 hours to make the Liquid A in the coating; the modified alicyclic amine is liquid B...

Embodiment 3

[0022]In 0.8 part of bisphenol A epoxy resin, 0.5 part of novolac epoxy resin, add 0.1 part of long-chain polyamine amide and polar acidic ester sodium salt, 0.05 part of derivatization of high molecular weight polycarboxylate amine by weight solution, 0.05 parts of polyether-modified polydimethylsiloxane solution, and 0.05 parts of alkyl-aryl-modified dimethylsiloxane solution, heated and controlled the temperature at 25 ° C, mixed, Stir at high speed, add 0.05 parts of fumed silica powder, 0.006 parts of carbon black, 0.3 parts of precipitated barium sulfate, 0.4 parts of mica powder, 0.2 parts of talc powder under the condition of stirring, stir at high speed for 0.25h and use sand Grind in a mill for 0.5 to 1 hour, then add 0.05 parts of γ-aminopropyltriethoxysilane solution, 0.5 parts of glass flakes and 0.1 part of activated polyamide wax while stirring, and stir at high speed for 0.25 hours to make the Liquid A in the paint; 1 part by weight of modified cycloaliphatic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com